For forensic toxicology use only.

This is an Application Brief and does not contain a detailed Experimental section.

This work compares Waters Otto SPEcialist, a semi-automated positive pressure sample preparation device, to the Hamilton Microlab STAR, a fully automated, vacuum equipped system, for a previously validated solid-phase extraction (SPE) application. This broadly applicable method involves the use of the Otto Software technology which provides comparable recovery to a fully automated system, and accurate, reproducible quantification of controlled drugs from urine samples in support of research in forensic toxicology.

Sample preparation is an integral part of a workflow process that is used to extract, purify, and concentrate samples prior to instrument analysis. Most often it is considered a rate limiting step and a source of errors in an overall bioanalysis workflow.1 The use of SPE, a common technique for sample preparation, can be implemented using either positive pressure with a nitrogen stream to push sample through a sorbent bed, or negative pressure with a vacuum to pull sample through a sorbent bed. There are reasons to choose one type of SPE process over another; for example, most positive pressure devices do not support processing large sample volumes so the use of a vacuum manifold is necessary. However, the use of a vacuum can have its disadvantages such as irregularities of pressure applied for individual wells and slower flow rates due to maximum pressure limits of a vacuum device.2 Another concern is the need to manually adjust pressure settings during the extraction process which introduces the possibility of human error. To mitigate this issue, there are fully automated sample preparation and extraction devices available on the market, but they can be expensive and cumbersome in size. However, the need to reduce human errors is critical for the improvement of an SPE workflow.3-6

The Otto SPEcialist, a compact and semi-automated sample preparation device, combines the more efficient use of positive pressure with software that autonomously changes the applied pressure to a sorbent bed through every step of the SPE process. This revolutionary device provides an overarching solution for improving analytical consistency during sample preparation and extraction without the extra cost. Additionally, unlike most other positive pressure manifolds it can process a wide range of sample volumes whether it be on the 96-well µElution scale, or a 6 cc cartridge format. The following work encapsulates the reliability that this new and seamless technology can provide when executing a solid-phase extraction method using the Otto SPEcialist Positive Pressure Manifold.

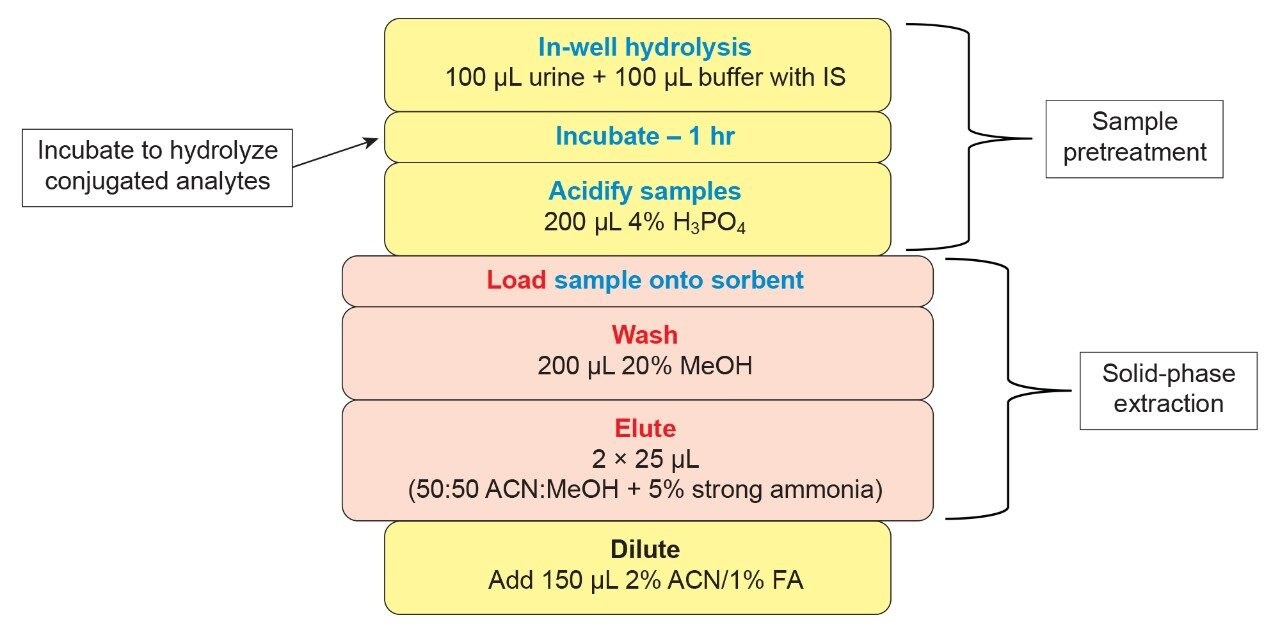

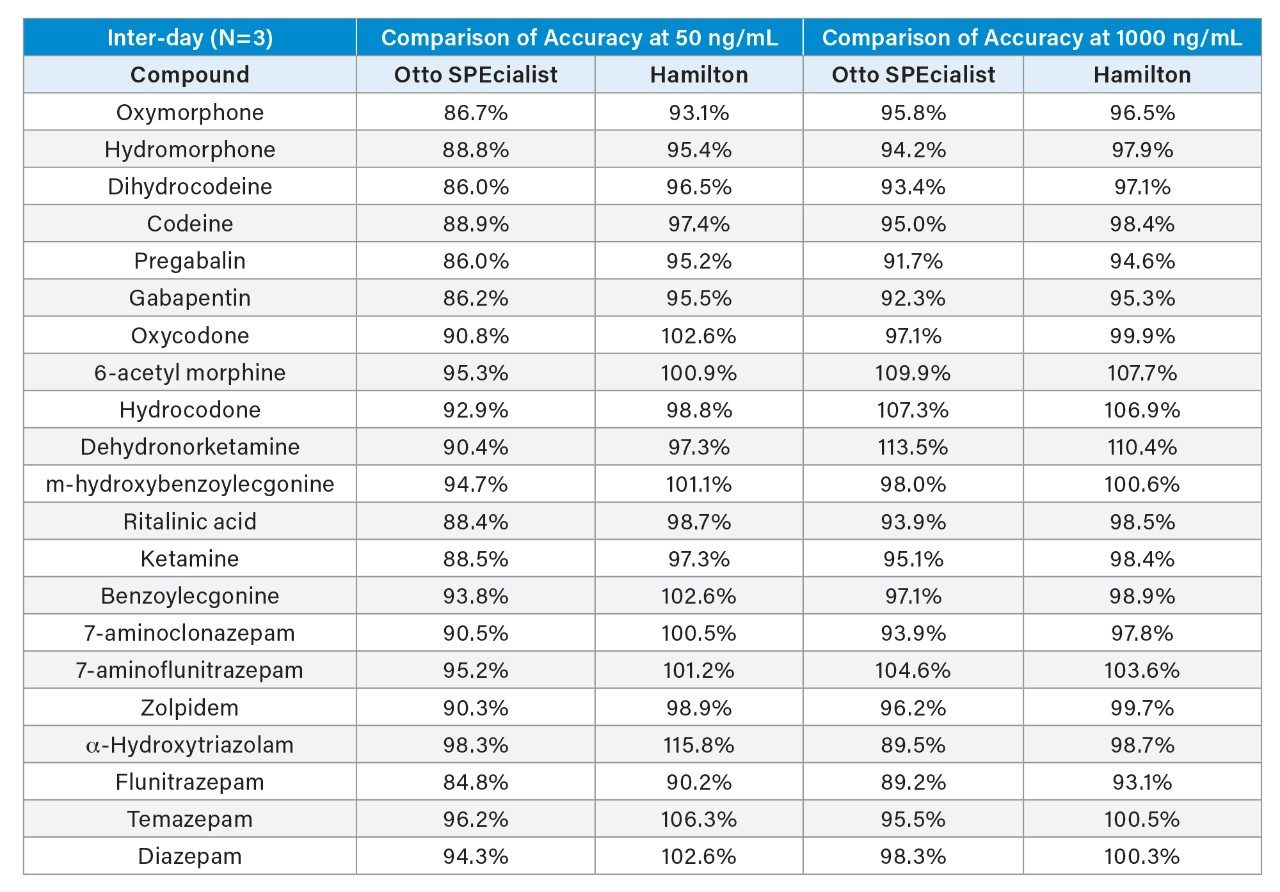

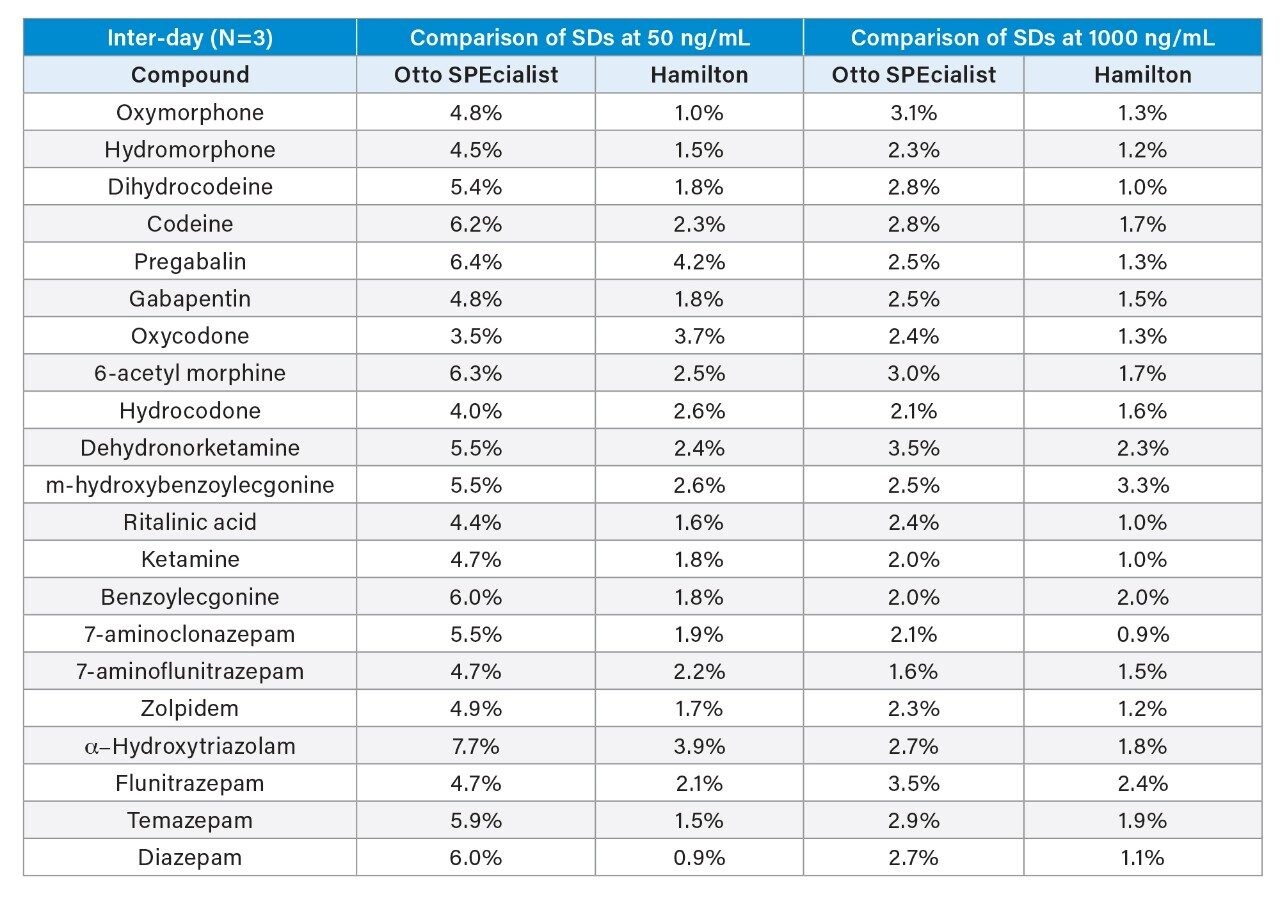

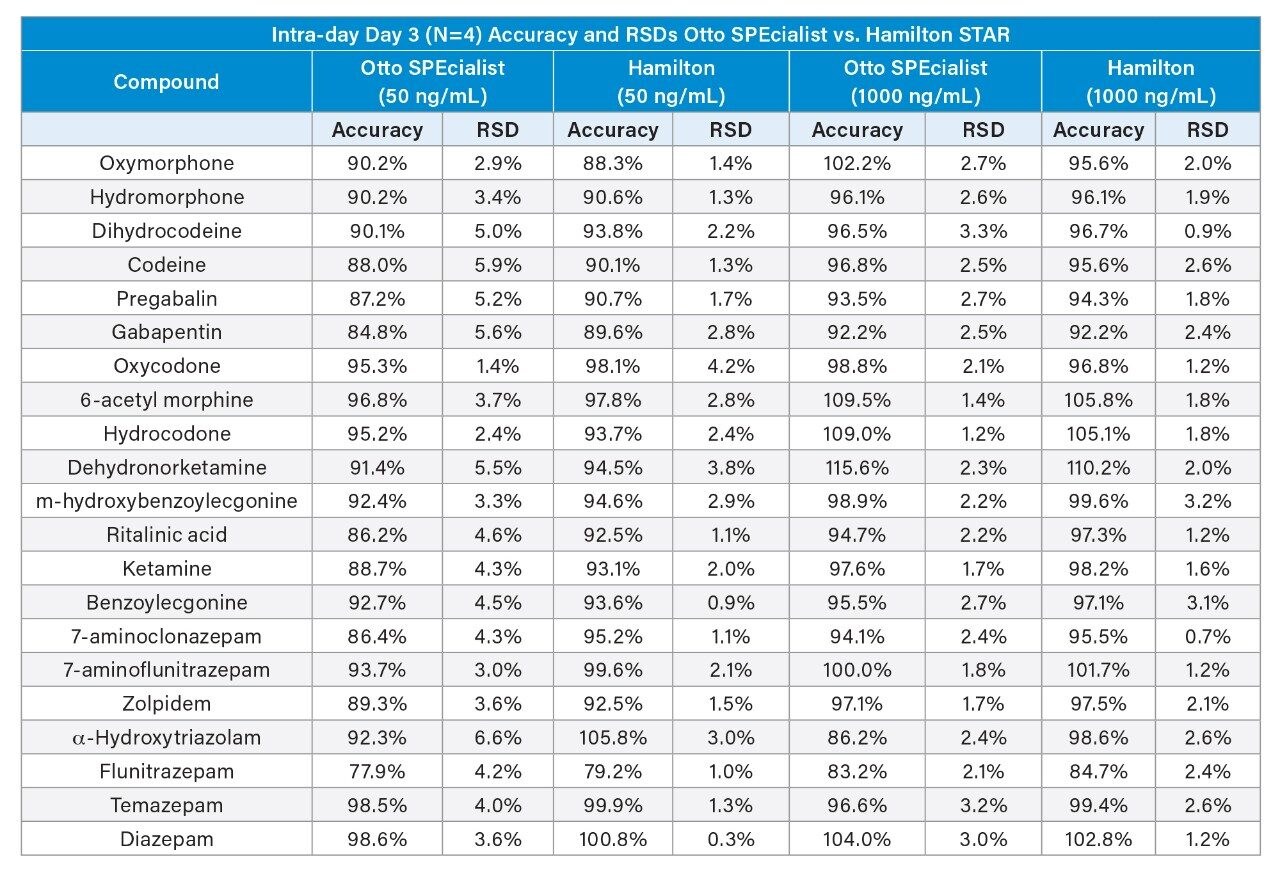

A panel of 21 drugs in pooled urine samples, spiked at a low (50 ng/mL) and a high (1000 ng/mL) concentration, were extracted in three batches over three days, with an N=4 per concentration in each batch. A detailed graphic of the sample preparation process can be seen in Figure 1. All samples were prepared manually in urine prior to extraction. A recovery experiment was conducted on two different sample processing platforms. All individual samples were extracted twice for every batch. One aliquot of each recovery sample was processed using the Otto SPEcialist and the other using the Hamilton Microlab STAR. For the Otto, samples were loaded, and wash and elution solutions were added manually by the user, while the manifold applied a positive pressure ramp using a pre-programmed method. The STAR carried out all liquid handling steps and SPE autonomously. Comparison of percent recoveries for the Otto to the fully automated system were comparable with inter-day recoveries for the low and high concentrations ranging from 85–98% and 89–113%, respectively; and standard deviations below 7.7% and 3.5%, respectively. The comparison of inter-day recoveries and SDs can be seen in Appendices 1 and 2, respectively. Intra-day (Day 3) recoveries of the Otto at low and high concentrations are between 78–99%, and 83–116%, respectively with RSDs below 6.6% and 3.3%, respectively. The comparison of intraday recoveries and RSDs can be seen in Appendix 3. More information on the full panel of analytes along with a thorough experimental section and validated method can be found in the Waters Application Note 720006187EN.7

This work demonstrates the reliability of the Otto SPEcialist Positive Pressure Manifold to perform an SPE that will give acceptable and comparable recoveries compared to a fully automated platform that involves virtually no human intervention. The Otto achieved robust and reproducible results across three days and three batches with total accuracies between 85–115% and SDs <8%.This semi-automated positive pressure device has an easy-to-use software interface, and a sleek and compact manifold that fits easily on a bench or under a hood. Methods can be transferred between devices to reduce user-to-user, and batch-to-batch errors. Unlike most fully automated systems that are costly and require a lot of time to learn how to program a method, the Otto is significantly less expensive, and its software is easy to learn for even the most novice of users. Overall, the Otto SPEcialist offers a simple and easy semi-automated approach to SPE.

720007067, November 2020