This application note focuses on using the Waters ACQUITY UltraPerformance LC System to separate and compare the ink-jet ink dyes from generic and brand vendor printer cartridges.

This application note focuses on using the Waters ACQUITY UltraPerformance LC System to separate and compare the ink-jet ink dyes from generic and brand vendor printer cartridges. Chromatographic separation is the most powerful and widely used technique to assess the stability, purity, and composition of dyes for product development and competitive product deformulation.1,2 The separation and analysis of the dyes from their impurities or in product formulations by conventional HPLC can be a difficult and time-consuming task. The typical HPLC run time is approximately 20 to 30 minutes to resolve dyes with similar chemical structures.1 The UPLC system can be used to rapidly resolve acid dyes and their impurities in less than 2 minutes and enable faster deformulation of ink-jet ink dye compositions.

Dyes 1 to 5 were dissolved in D.I. water to make standard solutions (4–40 μg/mL). Cyan, magenta, and yellow ink-jet solutions (0.5–4 μL) were extracted from ink-jet printer cartridges by pipette and diluted with 1–2 mL of D.I. water prior to UPLC analysis. All the sample solutions were filtered with 25 mm GHP Acrodiscs filters (WAT 200514) and placed in UPLC Max Recovery Sample Vials (screw cap 12 x 32 mm, 186000327C) for analysis.

|

System: |

ACQUITY UPLC with an ACQUITY UV absorbance detector |

|

Column: |

ACQUITY UPLC BEH SHIELD RP18 2.1 x 50 mm, 2.1 x 100 mm |

|

Column temp.: |

50 °C |

|

Weak wash: |

95:5 Water: CH3CN (500 μL) |

|

Strong wash: |

50:50 Water: CH3CN (50 μL) |

|

Seal wash: |

90:10 Water: CH3CN (5 min) |

|

Mobile phase A: |

10 mM NH4HCO3, pH 9.8 |

|

Mobile phase B: |

CH3CN |

|

Detection: |

UV absorbance |

|

Resolution: |

1.2 nm |

|

Sampling rate: |

20 pts/s |

|

Filter response: |

0.1 s |

Data were acquired and processed using Waters Empower Chromatography Software.

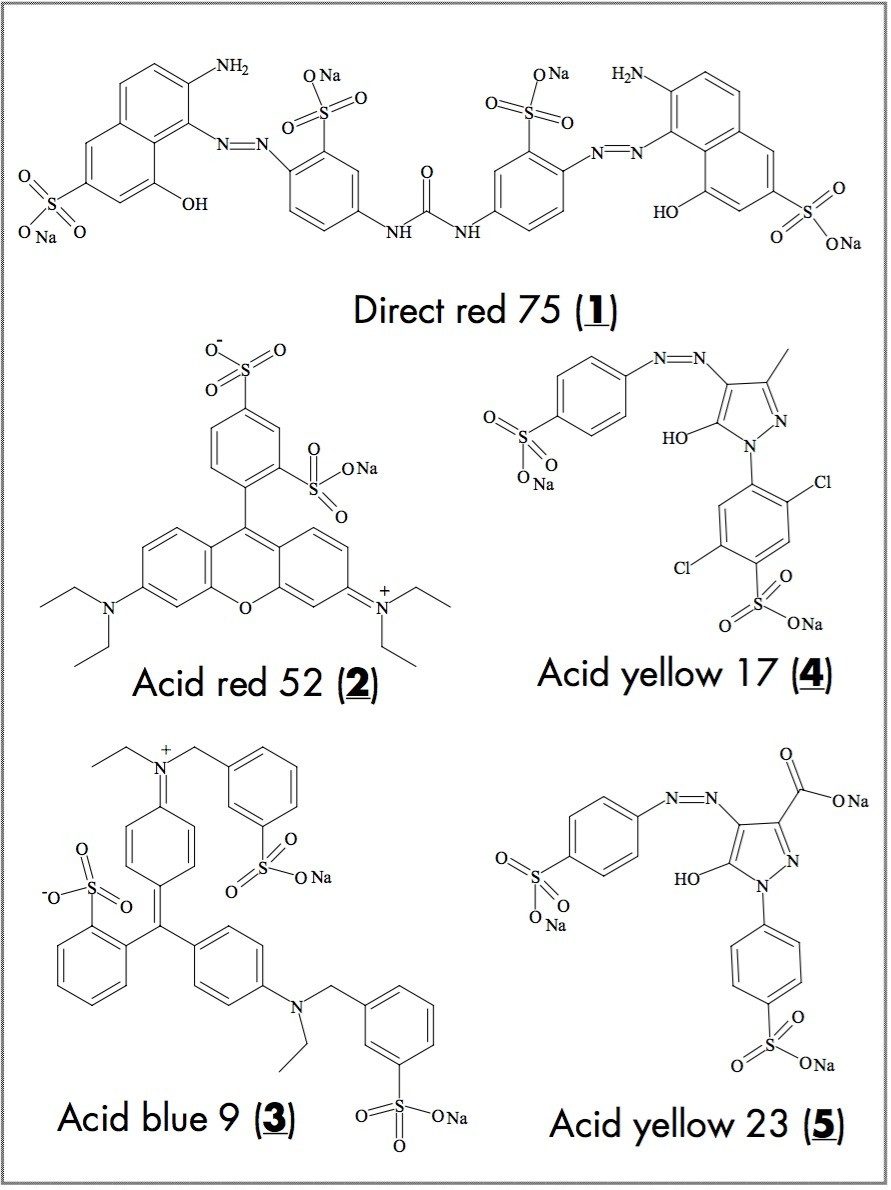

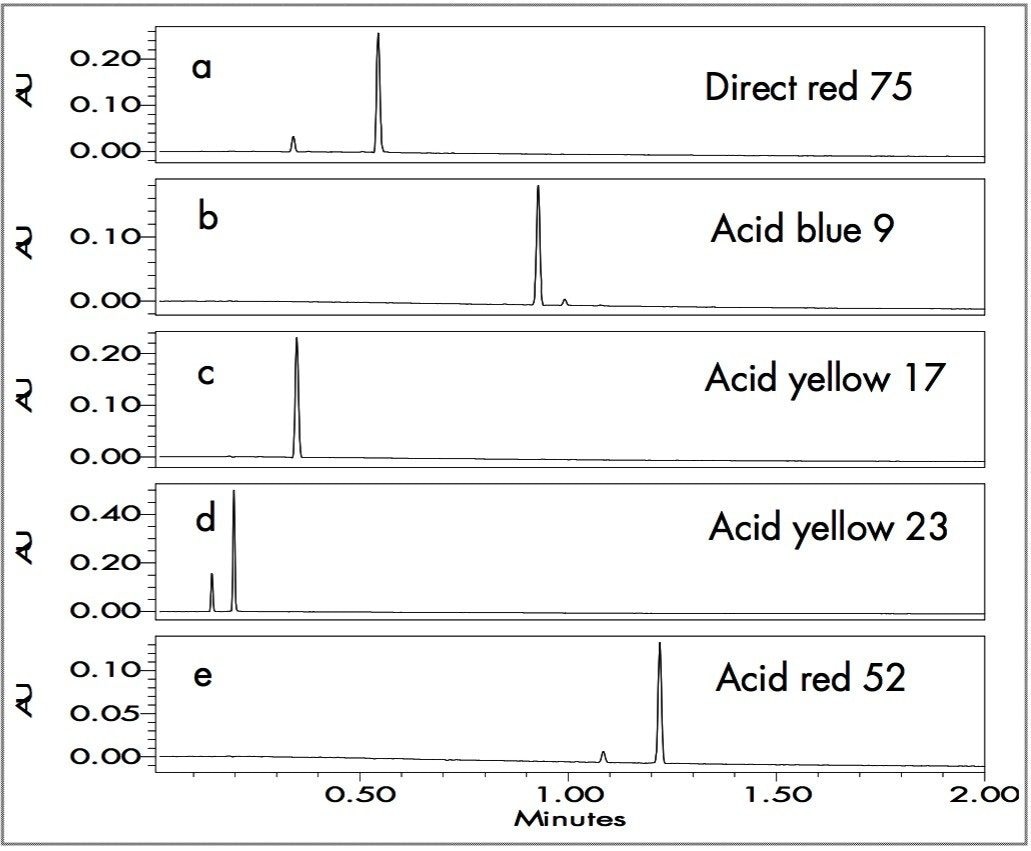

Five dyes (1 to 5, Figure 1) that are typical components in ink-jet inks were used to demonstrate the utility of UPLC for rapid identification and impurity profiling.3 Figure 2 shows that the dyes and their impurities can be rapidly resolved with a 2-minute linear gradient (5% to 55%B, 1 mL/min, 5 μL injection, and a 2.1 x 50 mm UPLC BEH SHIELD RP18 Column). The optimum separation was with pH 9.8 ammonium bicarbonate, mobile phase A.

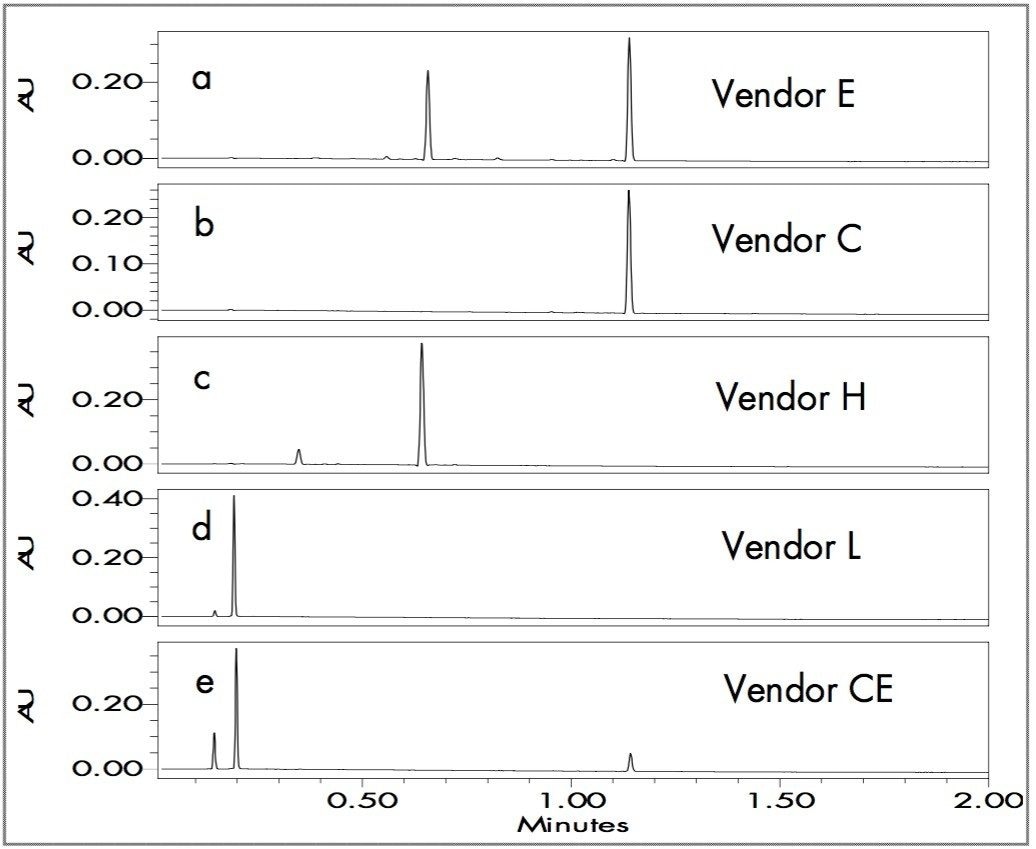

The same chromatographic conditions were used to profile dye components in yellow and magenta ink-jet ink printer cartridge solutions from five vendors. Figure 3 shows the chromatograms of yellow ink-jet inks. There are two major yellow dye components in Vendor E with retention time 0.66 and 1.14 minutes, respectively. The UPLC data show that the peak at 1.14 minutes is found in the yellow ink-jet ink formulations of Vendors C, E and CE; whereas Vendor H and Vendor E have the 0.66 minute peak dye component in their yellow ink-jet ink formulations. The first two peaks at 0.15 and 0.20 minutes in the Vendors L and CE yellow ink-jet inks are consistent with acid yellow 23 and its impurity peak.

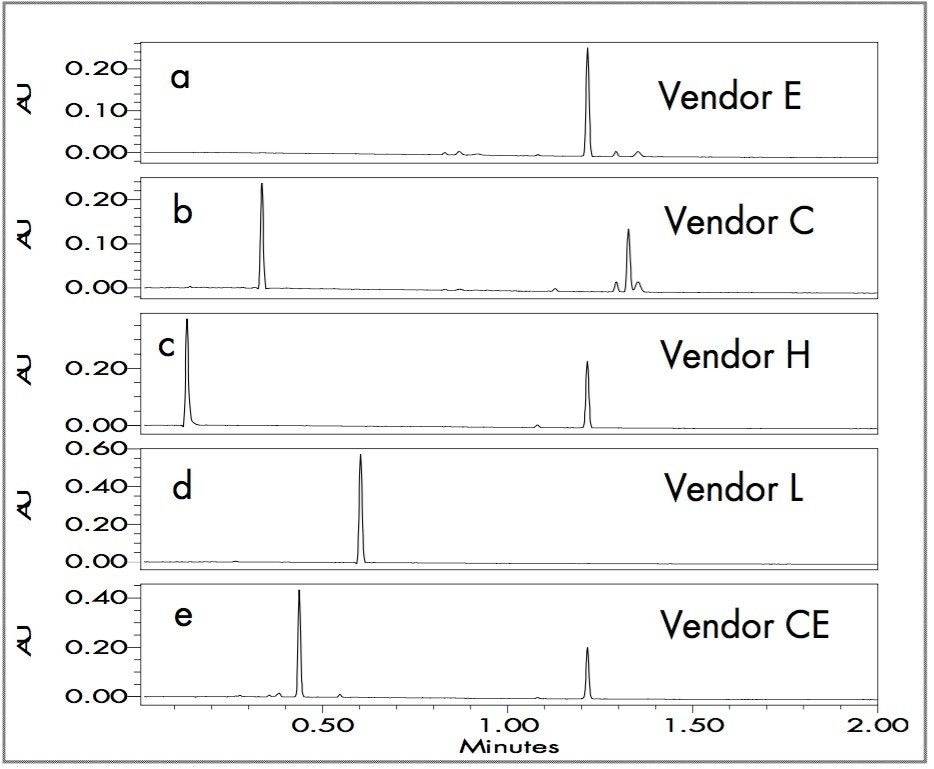

Figure 4 shows that one or two major red dye components were used to formulate magenta ink-jet inks. Acid red 52, retention time 1.22 minutes, was used by Vendors E, H, and CE.

The chromatograms of the cyan ink-jet inks are very different from the other inks. To provide more details about the cyan ink dye compositions, a 2.1 x 100 mm UPLC BEH SHIELD RP18 Column with a 10-minute linear gradient from 5% to 40%B at 0.5 mL/min (10 μL injection), was used.

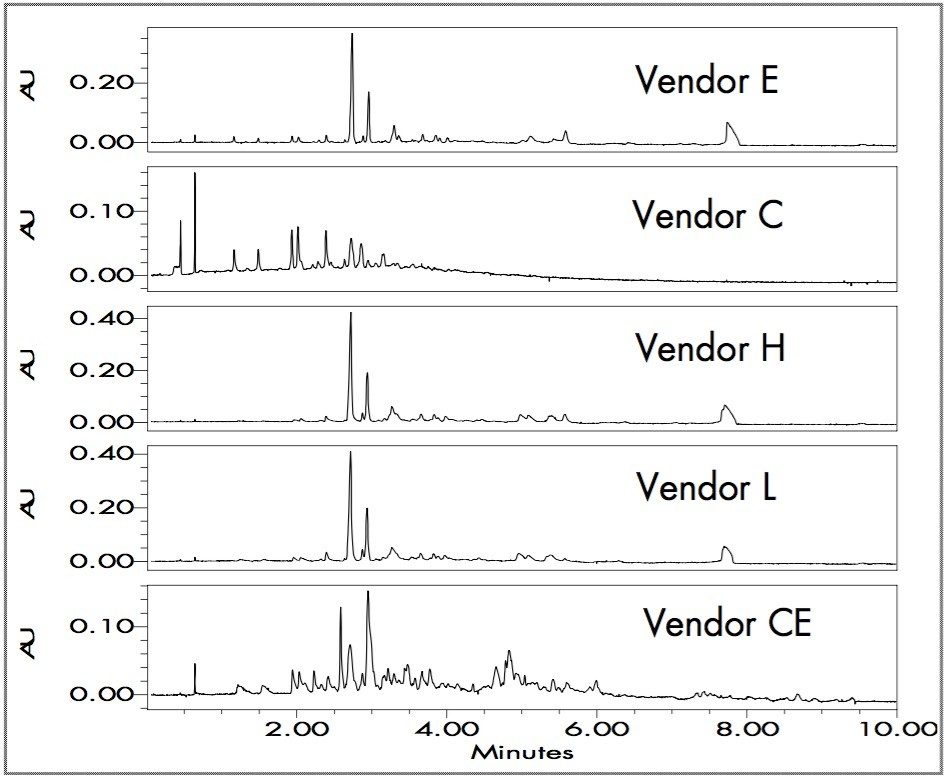

Figure 5 shows that, although the cyan ink-jet ink dye formulations are more complicated than the yellow and magenta ink dyes, the cyan color components are well resolved by UPLC. Qualitatively, the cyan ink-jet chromatograms of Vendors E, H and L are strikingly similar. All of the cyan ink-jet ink dye chromatographic profiles suggest a polymeric distribution.

It is plausible that all the products examined use chromophore-incorporated functional polymers for the cyan ink-jet inks.

For the analysis of dye components that are not in a standard mix or confirmation of chromophore-incorporated functional polymer, UPLC with an MS detector offers the potential to more easily provide additional details for competitive product analysis. Conventional analyses are time consuming.4,5

The Waters ACQUITY UltraPerformance LC System provides an easy and fast method for sensitive separation and comparison of ink-jet ink dyes. The UPLC BEH column technology enables the use of pH 9.8 for excellent selectivity and resolution power. UPLC is a powerful tool to resolve ink-jet ink dyes from printer cartridges of generic and brand vendors. Potential applications for analyzing the stability, purity and composition of dyes are product development, competitive analysis, patent infringement, quality control, and also forensic analysis.

720001334, September 2005