This is an Application Brief and does not contain a detailed Experimental section.

To increase the yield of γ-tocopherol from walnuts by systematically optimizing the SFE process, including extraction time, pressure, and temperature, using a Waters MV-10 ASFE System.

The MV-10 ASFE System, with its multi-vessel extraction capability and automated control software, is the only SFE system ideally suited for SFE method development and optimization.

Supercritical fluid extraction (SFE) has long been used for the extraction of neutraceuticals and bioactive compounds from various matrices. Leveraging the high diffusivity and liquid-like solvation strength of supercritical CO2, SFE generally offers a faster and more selective extraction, reduced organic solvent usage, and shorter dry down time by employing liquid CO2 as the main extraction solvent.

γ-tocopherol (γ-T) is found in many plant seeds, nuts and their oils, and is the major form of vitamin E consumed in the diet. Recent studies have shown that γ-T possesses unique antioxidant and anti-inflammatory properties. In addition, there is a significant inverse correlation between the intake of γ-T and prostate cancer. As a result, there is an increasing demand in supplementing γ-T fortified vitamins in diets.

The low polarity of γ-T (LogP =10.4) makes it an ideal candidate for SFE. Since process variables, such as temperature and pressure, could have a profound impact on the extraction yield, we describe a systematic optimization on the extraction of γ-T from walnuts by SFE.

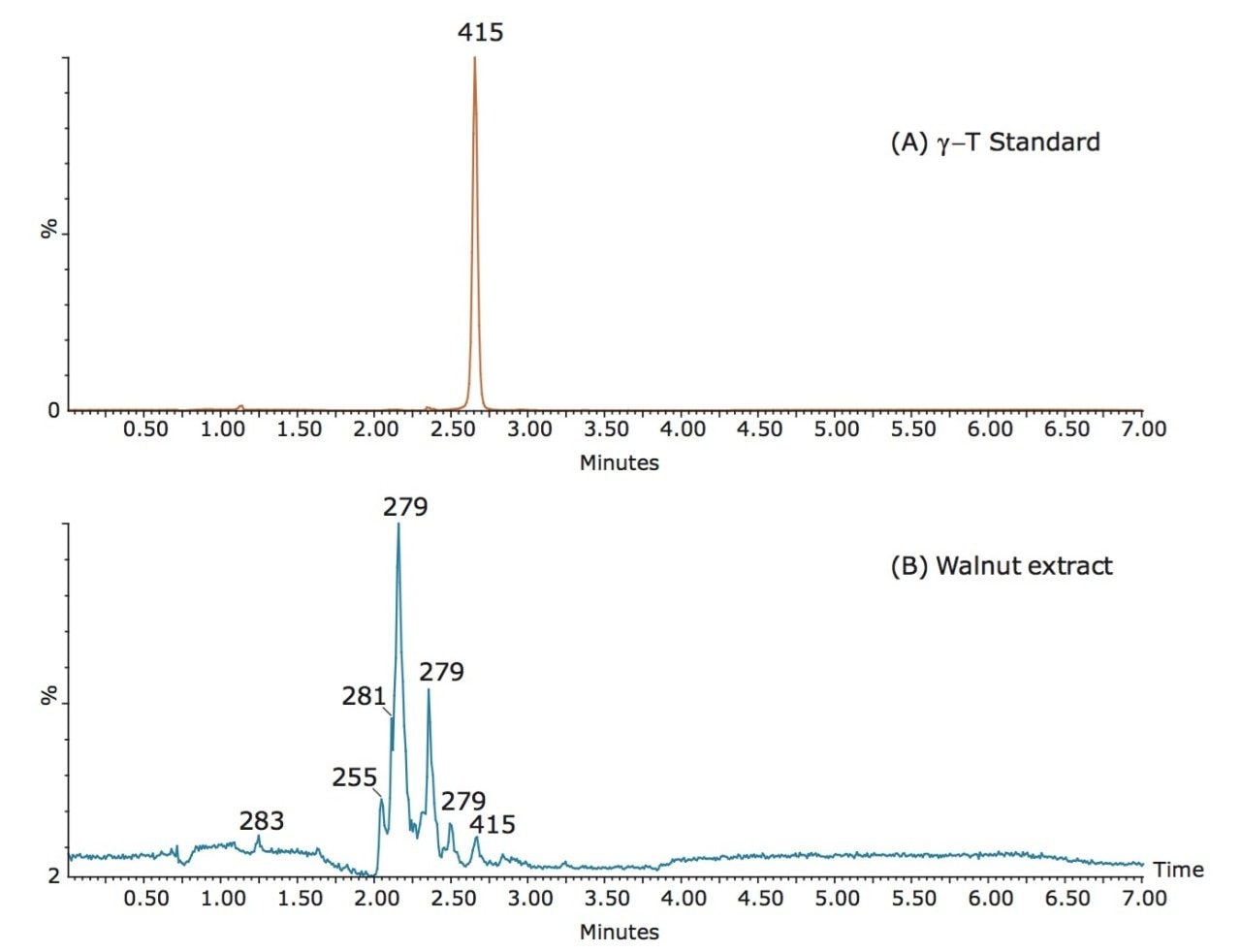

In order to quantify the extraction yield, a SFC-MS method was developed for the extract analyses, as shown in Figure 1.

All extraction experiments were performed on an MV-10 ASFE System. Three key extraction variables including time, pressure, and temperature were tested at different levels. For each extraction, a total of 10 g of minced walnuts was loaded onto a 25-mL finger-tight extraction vessel. The extract was then diluted in ethanol, and subject to SFC-MS analysis.

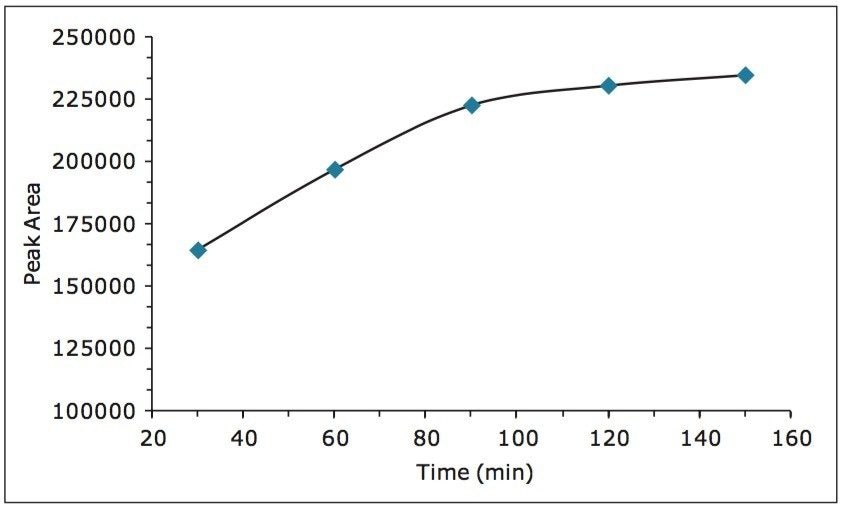

Figure 2 summarizes the effect of time on extraction yield. Clearly, the extraction yield started to plateau after 90 min, and longer extraction time led to small gain in yield. For example, a 60 min extraction of fresh walnuts could produce 16 times more γ-T than those additional gain by extending extraction time from 90 to 150 min. The results suggest that an extraction time between 90 and 120 min is a good compromise between yield and overall productivity.

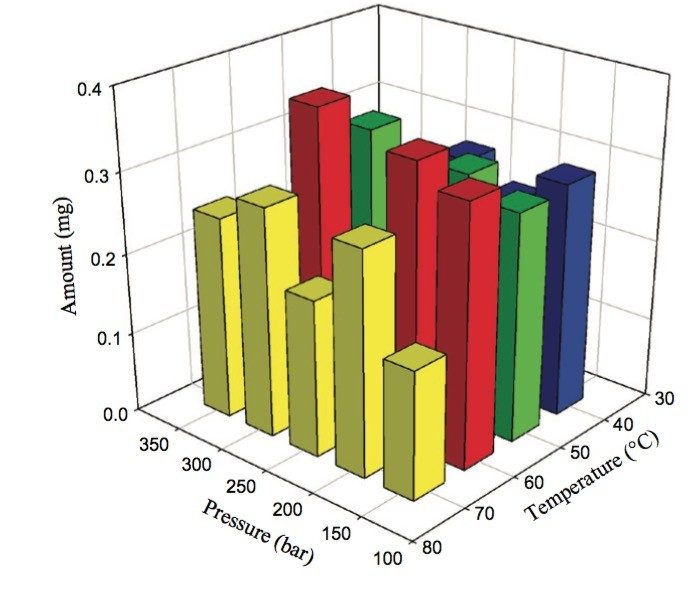

Next, four temperatures and five pressure settings were tested. Multiple extraction vessels were loaded with sample and placed in the MV-10 ASFE System multi-vessel column oven. The sequence was then run in an automated fashion using ChromScope Software. Since the main purpose of this step is to find the optima for both temperature and pressure, an extraction time of 30 min was used for all experiments to expedite the optimization. The effects of temperature and pressure on extraction yield are summarized in Figure 3. In terms of temperature, the yields reached their maximum between 50 and 60 °C. Increasing temperature to 70 °C led to decreased yield across all tested pressure settings. This is most likely due to the thermal degradation of the γ-T. The effect of pressure, on the other hand, is less straightforward. Nonetheless, an extraction pressure of 300 bar led to highest extraction yields at 50 and 60 °C.

The MV-10 ASFE System with ChromScope Software makes analytical scale method development by SFE easy and productive. In this example, three process variables across multiple vessel extractions were evaluated including extraction time, temperature, and pressure in an automated manner. Subsequent analysis graphically revealed that the optimal conditions were the following: 90 to 120 min extraction time, 300 bar extraction pressure, and 50 to 60 °C extraction temperature. The scale of the MV-10 ASFE System reduced the use of the raw material, and the resulting amount of solvent consumed. In addition, the multi-vessel format and programmable software control of the system minimized operator intervention, and allowed for expedited process optimization. The MV-10 ASFE System is ideal for SFE method development and optimization where a systematic evaluation of multiple variables is required.

720004274, April 2012