This application note briefly describes the use of Empower 2 Software for denatured fuel ethanol analysis and reporting.

Easy-to-use to analyze and report fuel ethanol according to ASTM D5501-04

Ethanol is becoming an increasingly important alternative fuel on a worldwide scale due to social, environmental, political and economic factors. Production from fermentation alone in the U.S. has increased from 1.6 billion gallons in 2000 to 3.4 billion gallons in 2004.1 To ensure use as a fuel product, the ethanol is denatured by the addition of alkanes before shipment. ASTM2 method D5501-04, “Determination of Ethanol Content of Denatured Fuel Ethanol by Gas Chromatography,” details the analysis.

Producer labs and analysts are busy monitoring the lengthy ethanol fermentation process. Using Waters Empower 2 Software to streamline the final denatured ethanol analysis can save time. When an analyst can automate GC column conditioning and equilibration, data processing and calculations according to ASTM D5501-04 recommendations and print a report by filling in a small amount of information and pressing a Run button, that analyst is available to do other work in the lab or plant. Record keeping is easier with Empower as well. The sample identifiers that a lab uses, such as, sample name, batch, lot number, are trackable, traceable and searchable.

This application note briefly describes the use of Empower 2 Software for denatured fuel ethanol analysis and reporting. The analytical system was comprised of an Agilent 6850 GC with an FID detector and a client server running Empower 2.

Standards were from a commercial source for the ASTM method.

|

System: |

Agilent 6850 GC with FID |

|

Software: |

Empower 2 |

|

Column: |

DB-1 100 m x 0.25 μ film |

|

Conditions: |

ASTM D5501–04 |

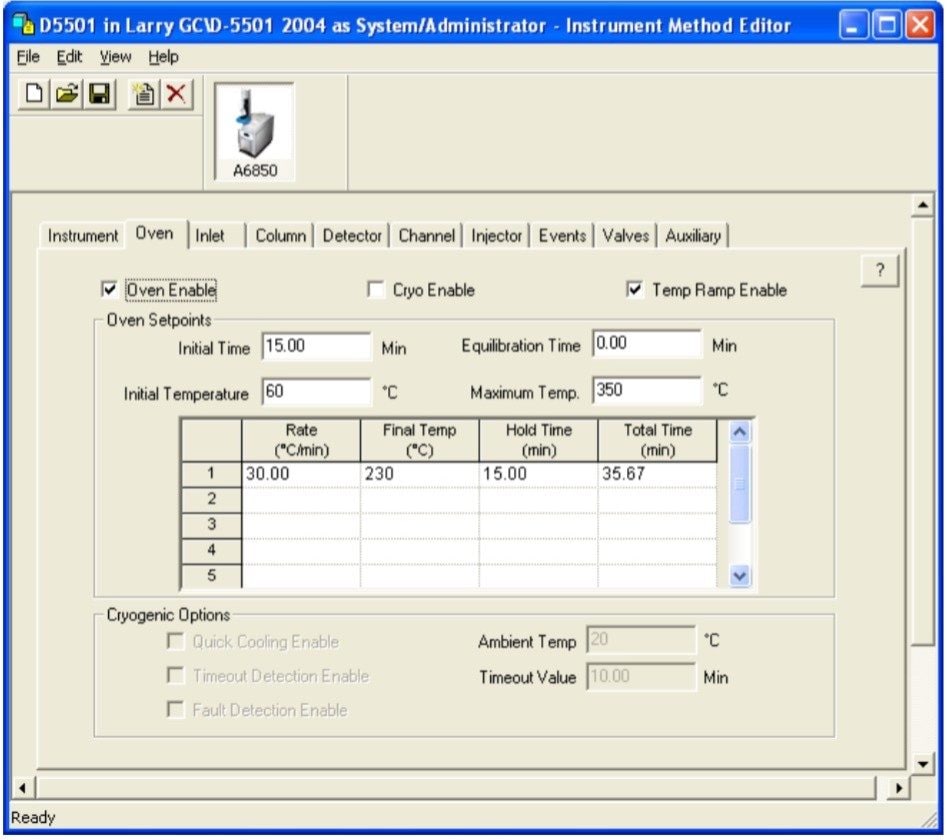

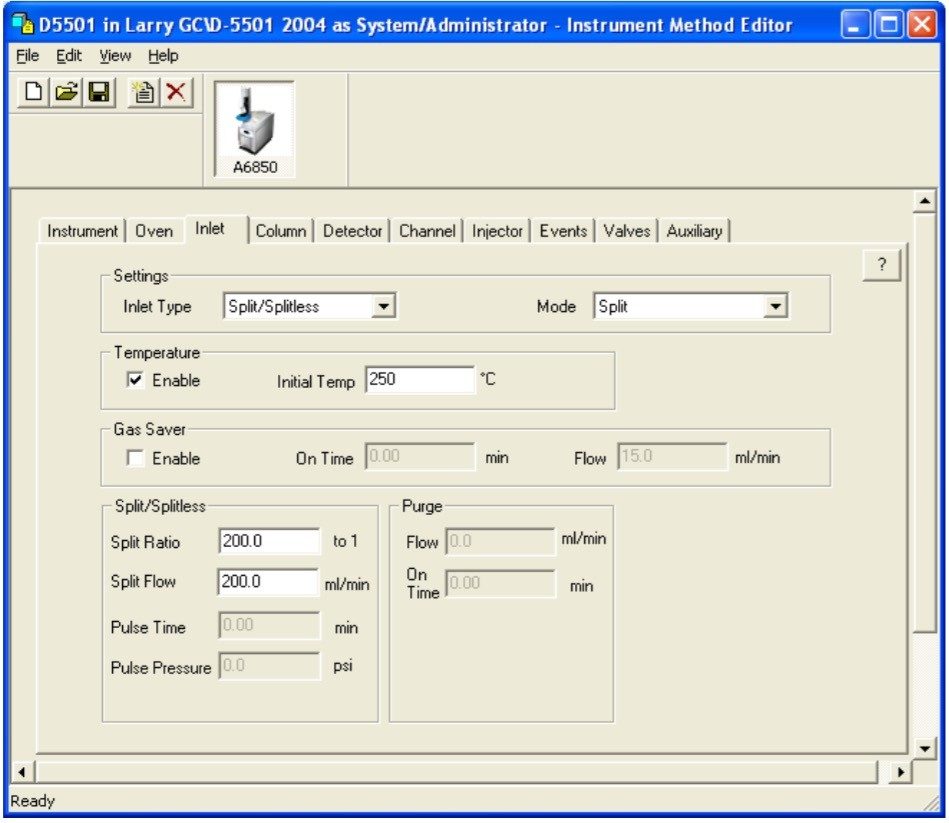

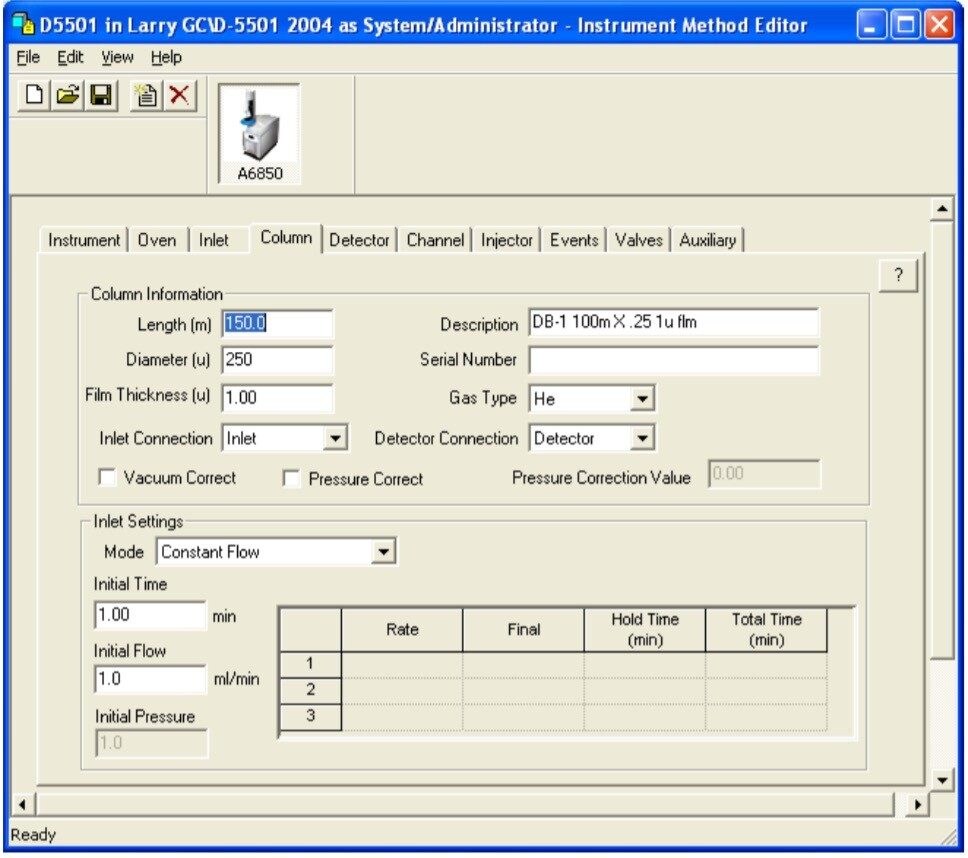

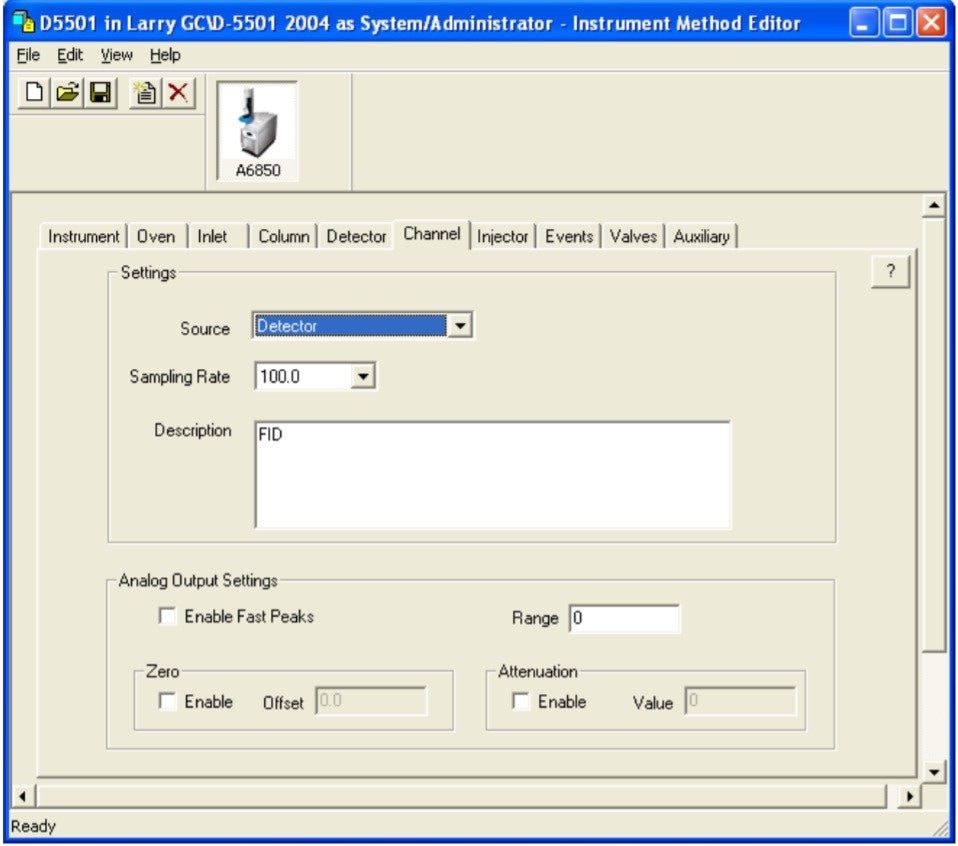

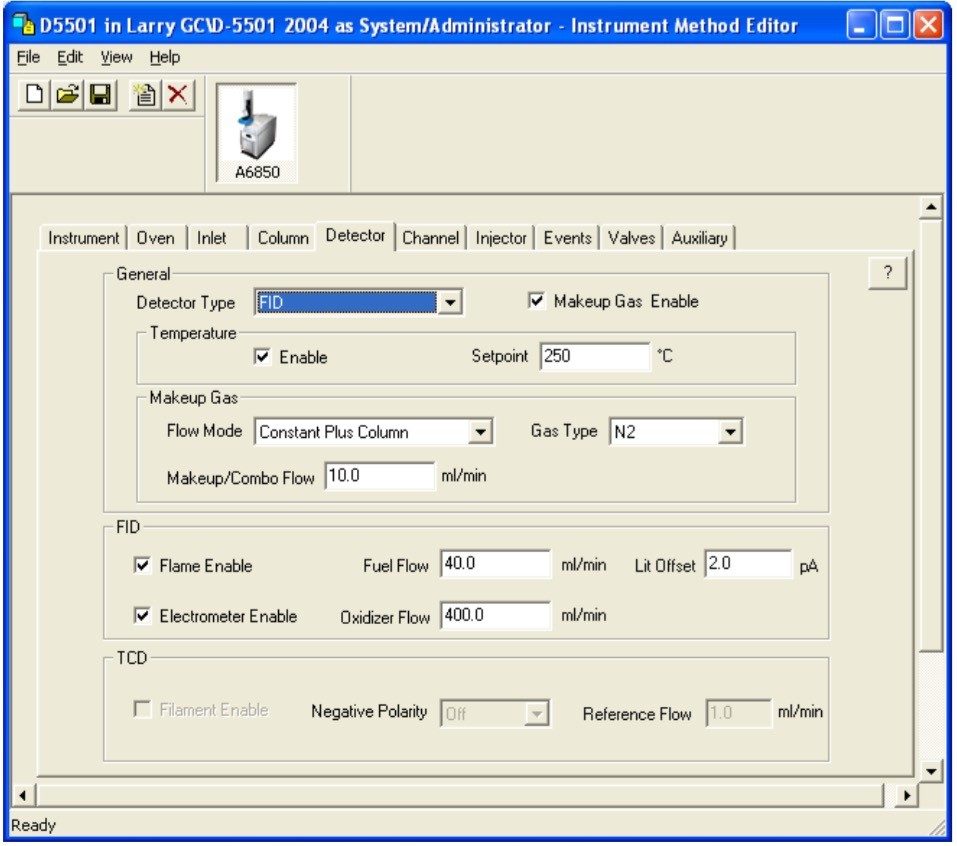

With Empower 2 Software anyone in the lab can easily automate the calculation and reporting of all the required values outlined in Section 12 of ASTM D5501- 04. The GC must be set up and run with parameters to comply with the ASTM method. These parameters are entered on individual tabs in the Empower instrument method (Figures 1–6).

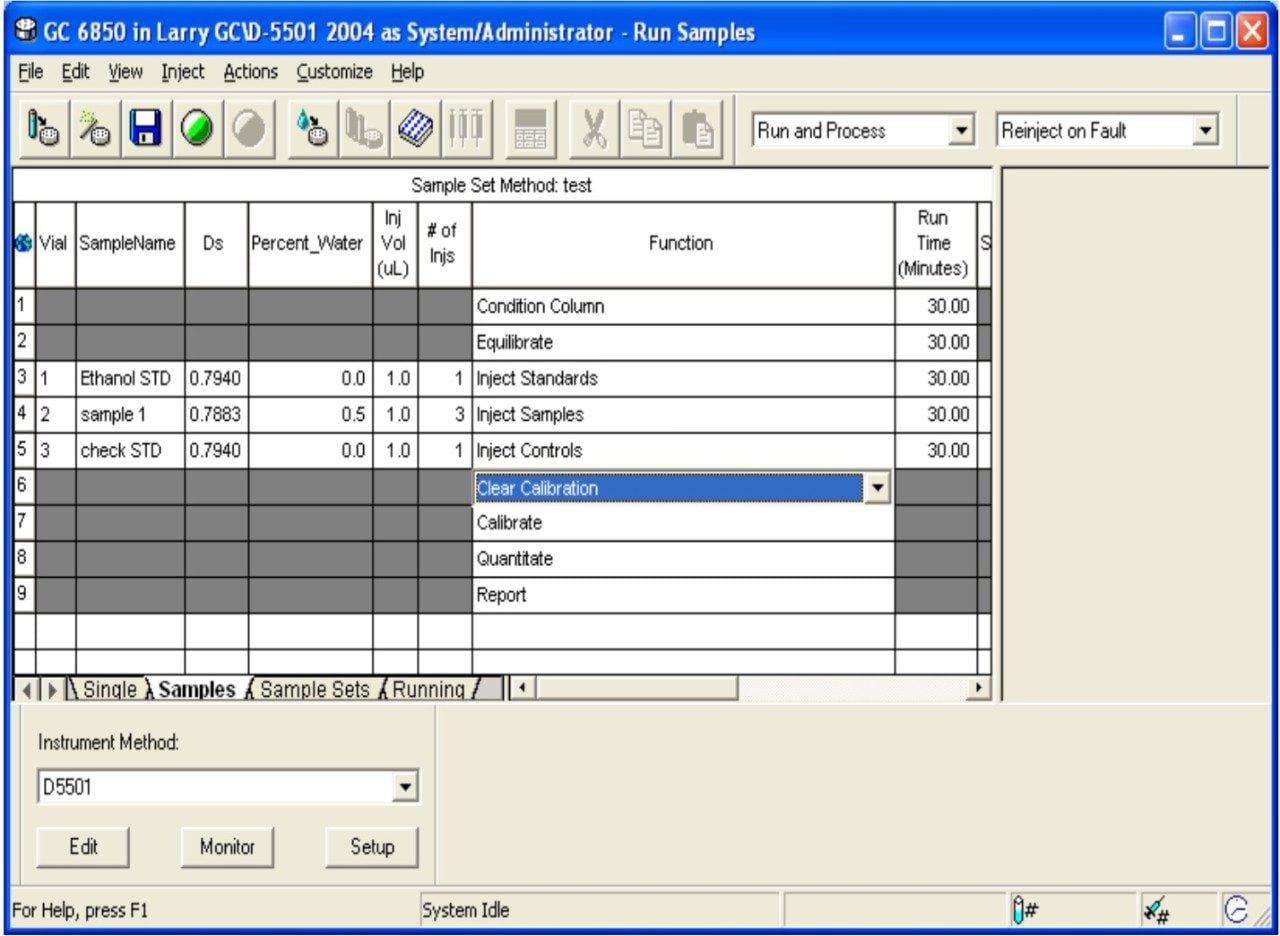

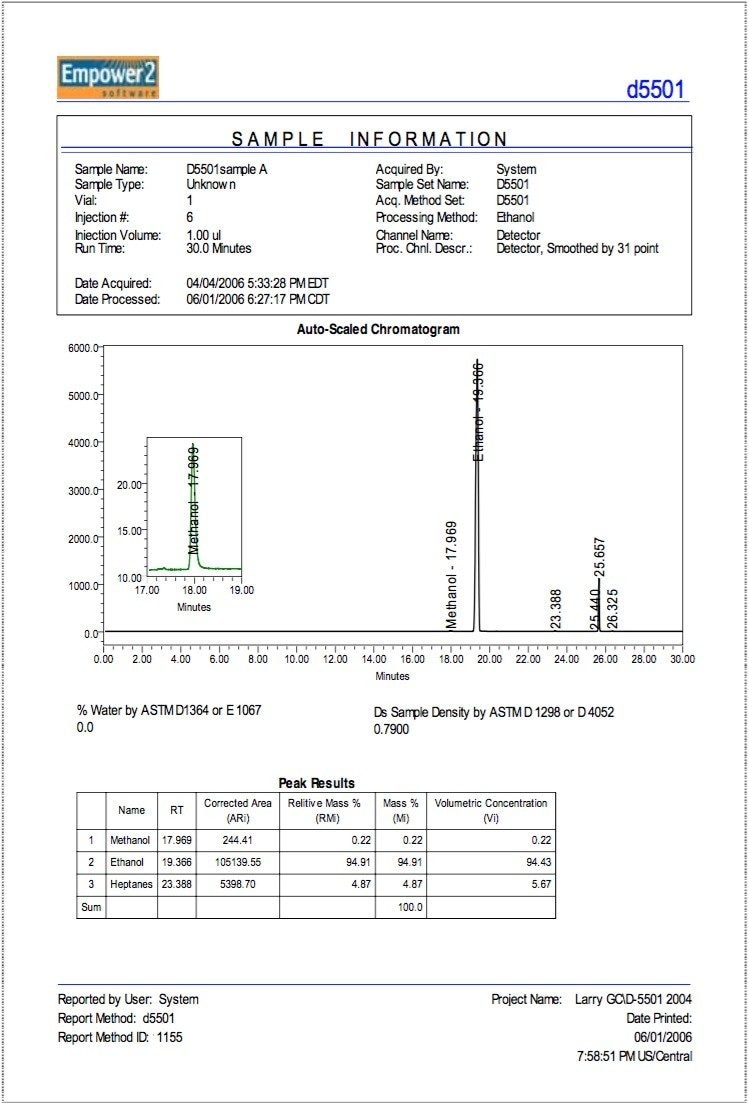

To run samples, the next area of the software to use is the RUN SAMPLES page (Figure 7). When a sample template is used, the lab analyst only enters a minimum of information reducing the data entry burden. Data fromtwo other required tests can be entered, stored, searched and plotted. Ds is the sample density determined using ASTM method D 1298 or D 4052 and % water is calculated using ASTM D1364 or E 1064. These data are needed to calculate the final % Mass of alcohols. If the sample density and % water are unavailable when the GC analysis is run, the values can be entered later and the final result calculated.

Critical to success in daily operation is ensuring that unattended systems generate quality data. With Empower 2 you can do more than just set up initial conditions and wait for temperatures to meet set points. The software has features that allow easy automation and monitoring of system setup, column conditioning, system equilibration and calibration, running samples, performing required calculations, and printing a custom report. This interactive process ensures the analysis begins, runs properly and generates data. Control values can also be set using the System Suitability option. This feature analyzes the data from eachinjection relative to defined parameters, such as retention time or response. If the value is outside tolerance, the user can set the system to take corrective action, for example, re-inject of the sample or stopping the run completely.

After the analysis has been run, Empower 2 can be set up to automatically process the data, performcalculations and report results. There are three key benefits to these features. First is the ability to smooth the GC FID data with software as opposed to filtering the data in the hardware.

In the processing method the user can define both the smoothing type and by how much the raw data should be smoothed (Figure 8). This is important with high speed data typically collected today. The data shown in Figure 11 were collected at 100 Hz. Second, performing calculations to meet the needs of Section 12 of ASTMD5501 can be done automatically with Empower 2 instead of using a calculator or spreadsheet.

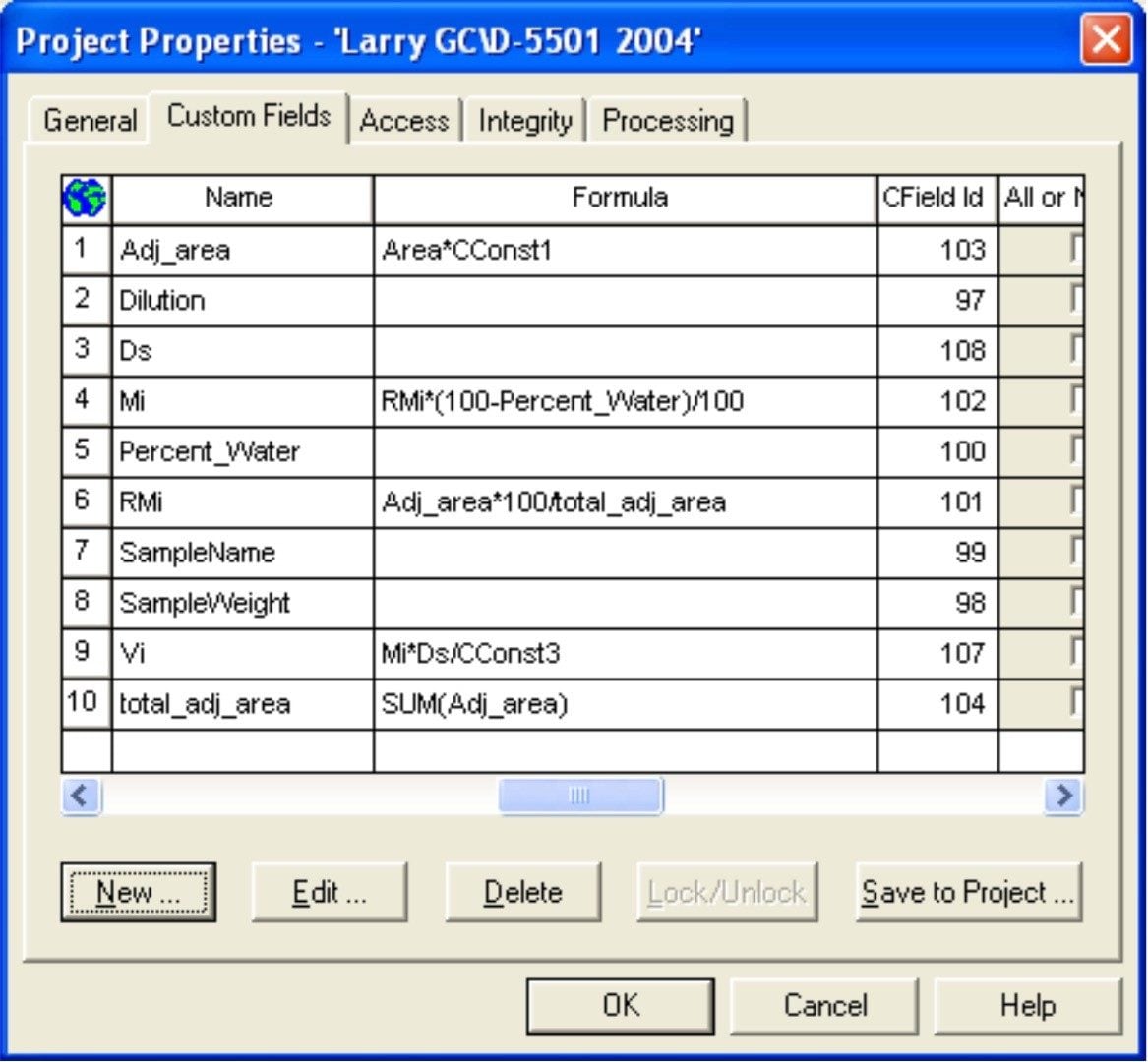

A unique feature of Waters Empower 2 Software is Custom Fields, a tool that lets users define equations for their needs in standard math syntax not a programming code (Figure 9). The interface is as easy to use as writing an equation on a piece of paper. These custom fields meet the needs of Section 12.

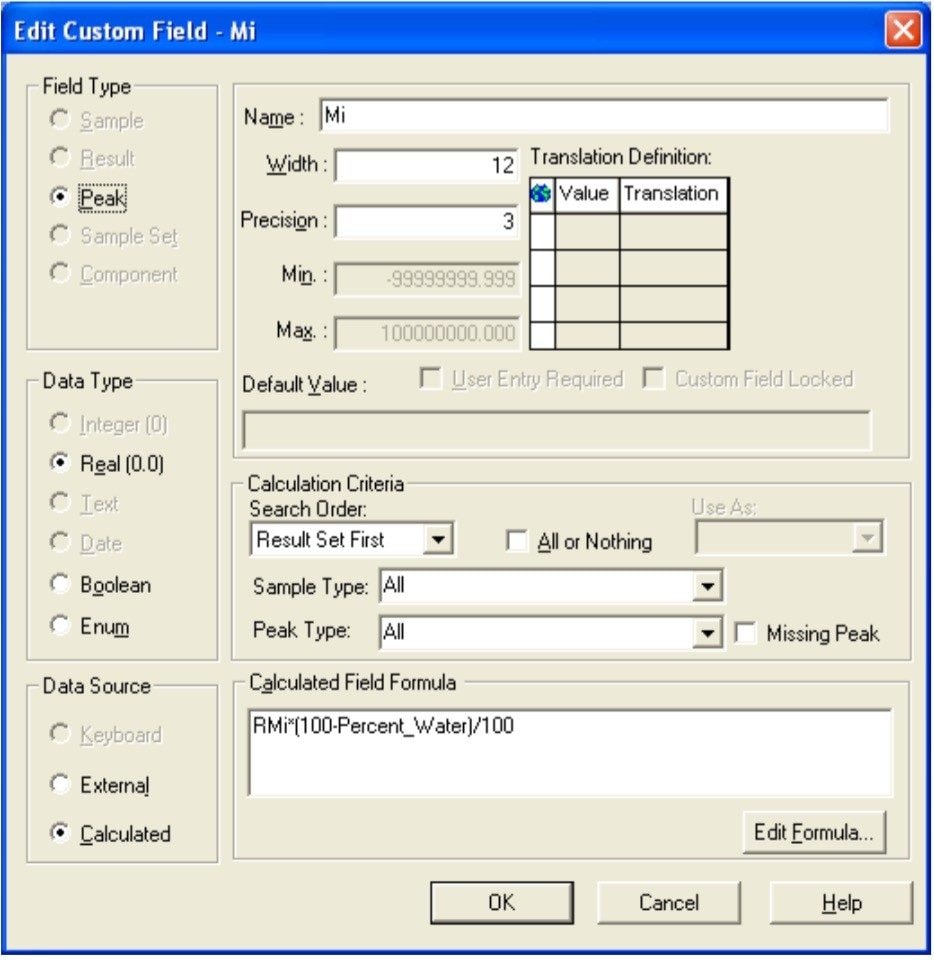

The equation for the custom field, %mass or Mi, was created using simple math. Empower 2 is easier to use than writing an equation on a piece of paper (Figure 10).

The third key benefit of Empower 2 software is the reporting capability. After setting up templates and fields one time, the system can automatically print a report. The report is fully customizable. Figure 11 is an example of such a report.

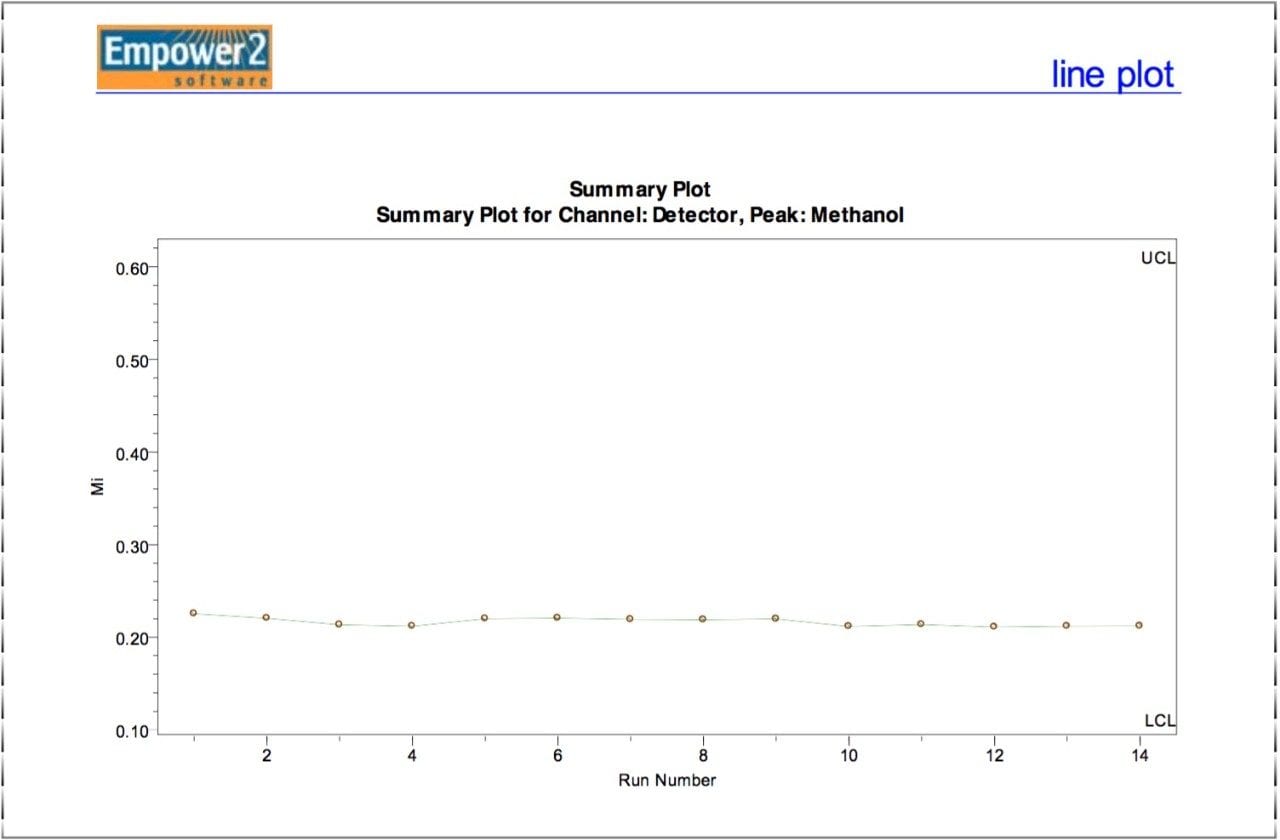

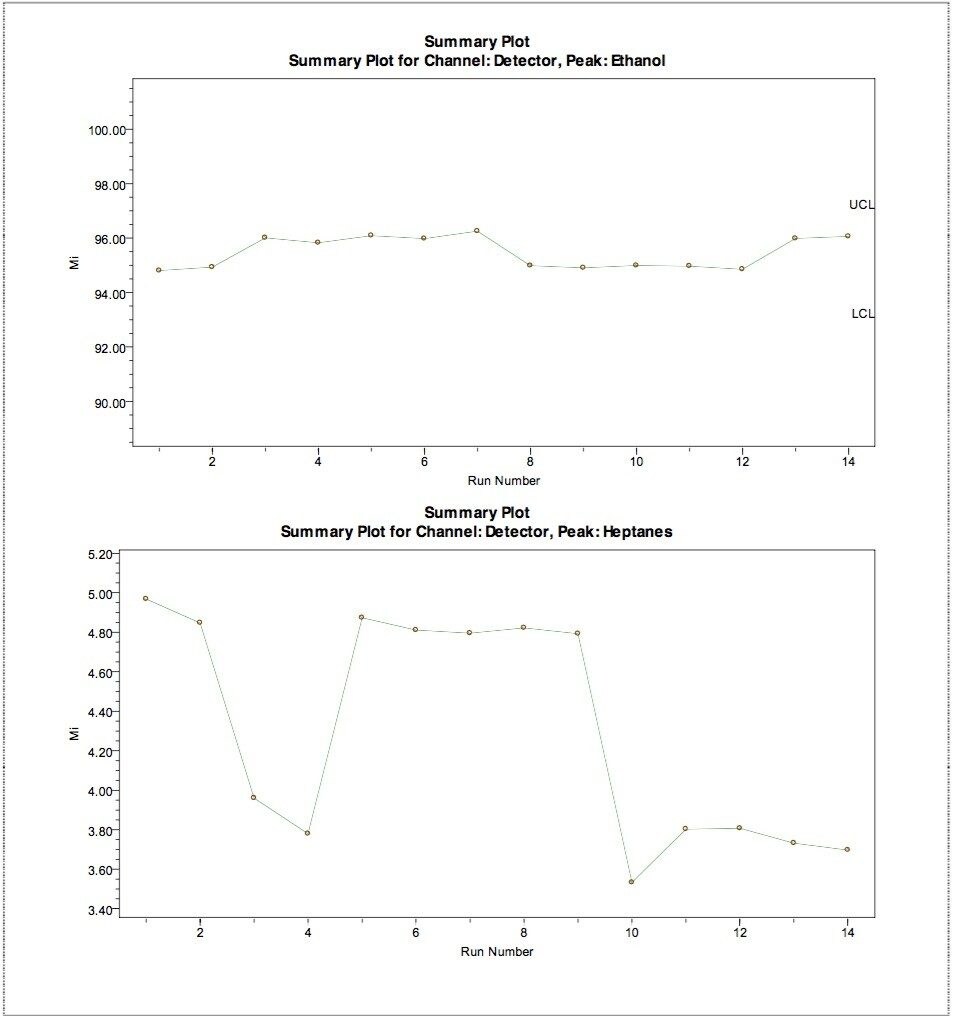

Besides sample information, Empower 2 software can be used to generate reports for tracking and trending data. Figures 12 and 13 are summary plots of 14 ethanol batches showing the % Mass (Mi) for methanol, ethanol and the heptanes. The Limit bars in Figure 13 were set as part of the system suitability.

Empower 2 Software is easy-to-use to analyze and report fuel ethanol according to ASTM D5501-04. The software allows use of a template that includes instrument parameters such as conditioning and equilibration, data processing instructions and report instructions. The equations needed to calculate required values, such as % mass, can be built-in one time with the Custom Field feature and re-used. All the analyst must do is load the sample and a template, enter minimum information and hit run. After the run is finished, the analyst can be confident that quality data are printed. Using interactive system suitability, runs can be re-injected or stopped based on user pre-defined limits. With the System Suitability option, more advanced trending and tracking data features are available.

720001840, July 2006