In compliance with global regulations, and in order to offer consumers safer products, major textile and leather product manufacturers and retailers use the Oeko-Tex label as a product certification. This certificate limits the maximum amount of carcinogenic aromatic amines to no more then 20 mg/kg. To be more cost effective, there are growing demands for faster and more accurate analytical methods to test for these aromatic amines in consumer products.

This work illustrates that the ACQUITY UPLC H-Class System, combined with ACQUITY SQD and Empower 3 Software enables rapid, selective, and sensitive analysis of aromatic amines from textiles.

Using the ACQUITY UPLC H-Class System coupled with the ACQUITY SQ Detector, 26 carcinogenic aromatic amines can be detected at legislated levels.

Azo dyes are commonly prepared by coupling of a diazonium compound with a phenol or an aromatic amine.1 They are used in a wide variety of consumer goods, including clothing, leather, food, toys, mineral oils, waxes, medical devices, plastics, and cosmetics.2,3 There are more than 3,000 azo dyes that are available in a broad spectrum of colors and these represent more than 65% of the global dye market.2 Some of these dyes can be reduced in vivo through cleavage of the azo groups (-N=N-), forming mutagenic and carcinogenic aromatic amines.3 The main routes of exposure for azo dyes and their degraded products are regular skin contact, such as ingestion or dermal absorption through clothes containing these dyes.2,3 The potential health risk of carcinogenic aromatic amine exposure to consumers has led to strict government regulations worldwide. U.S. FDA regulations 21 CFR 74.705 and 21 CFR 74.706 restrict the use of azo food dyes that could degrade into carcinogenic aromatic amines. EU Directive (2002/72/EC) prohibits the use of food contact materials that release carcinogenic amines. EU Directive (2002/61/EC) bans the use of certain azo dyes in textile and leather articles, which are largely based on existing German legislation. The European Union regulated limit for 24 listed carcinogenic aromatic amines is 30 mg/kg of each. China has similar regulations but the regulated limit is 20 mg/kg.4 In addition, the Oeko-Tex, which is being widely adopted by textile manufacturers, has regulations on textile products for 24 aromatic amines, of which 22 overlap with the European legislation.5

In compliance with global regulations, and in order to offer consumers safer products, major textile and leather product manufacturers and retailers use the Oeko-Tex label as a product certification. This certificate limits the maximum amount of carcinogenic aromatic amines to no more then 20 mg/kg.5 To be more cost effective, there are growing demands for faster and more accurate analytical methods to test for these aromatic amines in consumer products.

At present, the standardized procedures used in analytical laboratories for the determination of aromatic amines in textiles are laborious and timeconsuming.6,7,8 A recent publication (Garcia-Lavandeira et al., 2010) presented an alternative sample preparation procedure for the determination of aromatic amines in textiles2. This sample preparation and a 10-minute separation method on the Waters ACQUITY UPLC H-Class System with SQ Detector and Empower 3 Software were used to analyze samples following the extraction and reduction of azo dyes from fabric.

The standards of o-anisidine, benzidine, 4,4’-diaminobiphenylether, 4-chloroaniline, 2-amino-4-nitrotoluene, p-cresidine, 2-naphthylamine, 4-chloro-o-toludine, 2,4,5-trimethylaniline, o-aminoazotouene, 4-biphenylamine and o-toluidine were purchased from Sigma-Aldrich. 2,4-diaminoanisole, 2,4-diaminotoluene, 4,4’-diaminobiphenylmethane, 2,4-xylidine, 4,4’-diamino-3,3’-dimethylbiphenylmethane and 4-aminoazobenzene were purchased from Fluka. 2,6-xylidine, o-dianisidine, 4,4’-diaminobiphenylsulfide, aniline, 1,4-phenylenediamine were purchased from Acros Organic. o-toldine and 3,3’-dichlorobenzidine were purchased from Fisher Scientific. 4,4’-diamino-3,3’-dichlorobipheylmethane was purchased from TCI America. These 26 aromatic amine standards were dissolved in methanol to make a stock solution of 1 mg/mL each. Calibration standards were diluted from stock solutions with 5% methanol.

This method describes sample preparation for textiles made of cellulose and protein fibers such as cotton, viscose, wool, and silk. The sample preparation of aromatic amines for textile material involves simultaneous extraction and reduction of the azo dyes into aromatic amines. Briefly, a cotton textile sample was cut into small pieces, and 1 g was weighed into a 50-mL round bottom flask. 17 mL of 0.06 M citrate buffer solution, pH 6.0, was preheated to 70 °C and added to the flask. 3 mL of freshly prepared 200 mg/mL sodium dithionite solution was immediately added to the flask. The flask was sealed tightly, and the reaction was allowed to proceed for 30 min at 70 °C (± 2 °C). The mixture was allowed to cool to room temperature and then it was filtered through a 0.2-μm PTFE filter and placed into a Waters certified vial for analysis.

|

LC system: |

ACQUITY UPLC H-Class |

|

Runtime: |

10.0 min |

|

Column: |

ACQUITY UPLC BEH C18 1.7 μm, 2.1 x 50 mm |

|

Mobile phase A: |

10 mM ammonium acetate in water |

|

Mobile phase B: |

10 mM ammonium acetate in methanol |

|

Flow rate: |

0.5 mL/min |

|

Injection volume: |

10 μL |

|

SL. No. |

Time (min) |

Flow rate (mL/min) |

%A |

%B |

Curve |

|---|---|---|---|---|---|

|

1 |

Initial |

0.5 |

95 |

5 |

- |

|

2 |

1.00 |

0.5 |

95 |

5 |

6 |

|

3 |

3.10 |

0.5 |

75 |

25 |

6 |

|

4 |

6.10 |

0.5 |

59 |

41 |

6 |

|

5 |

8.00 |

0.5 |

0 |

100 |

6 |

|

6 |

10.00 |

0.5 |

0 |

100 |

6 |

|

MS system: |

ACQUITY SQ Detector |

|

Ionization mode: |

ESI positive |

|

Capillary voltage: |

3.5 kV |

|

Source temp.: |

150 °C |

|

Desolvation temp.: |

450 °C |

|

Desolvation gas: |

900 L/H |

|

Acquisition: |

Selected Ion Recording (SIR) |

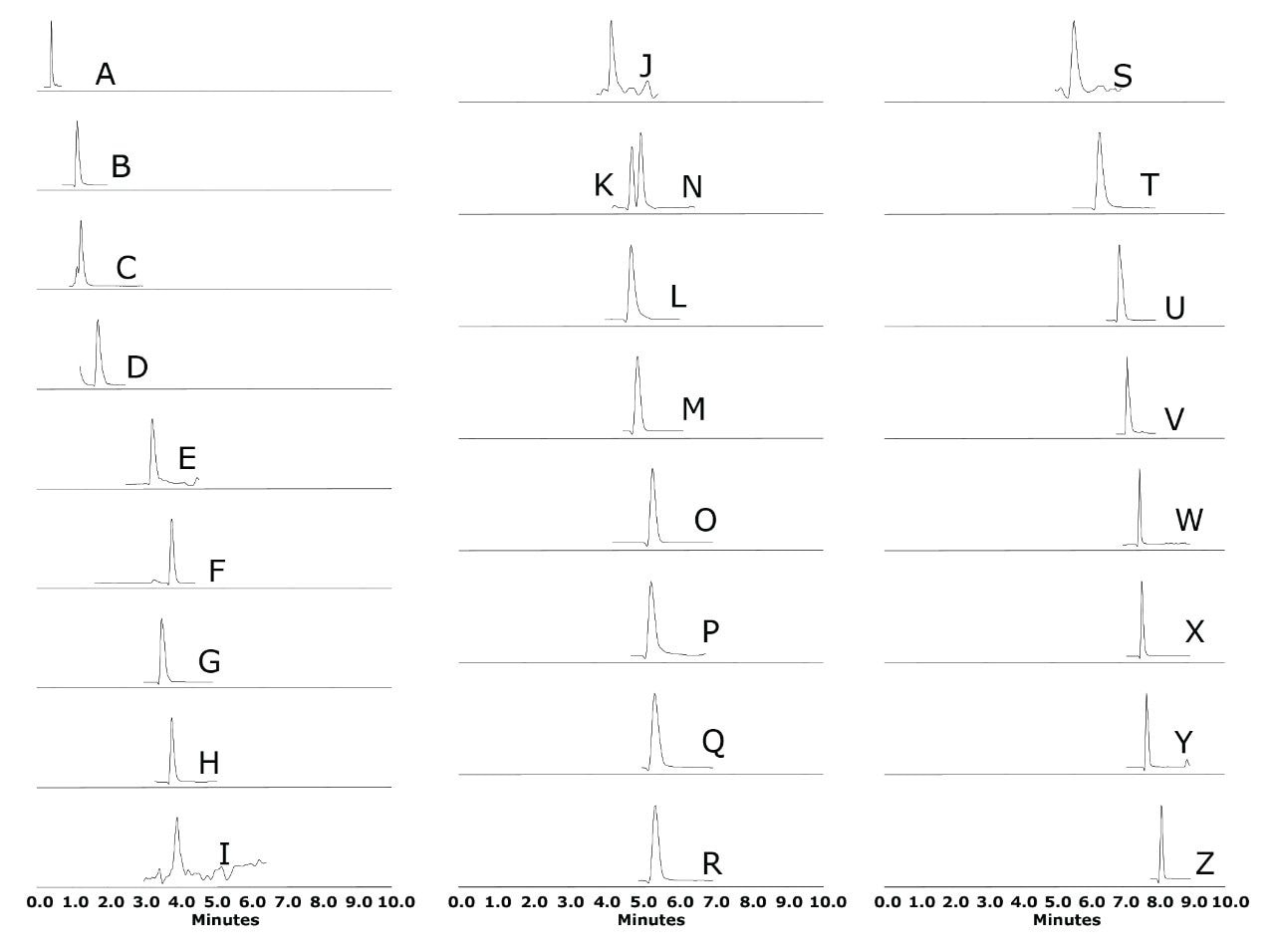

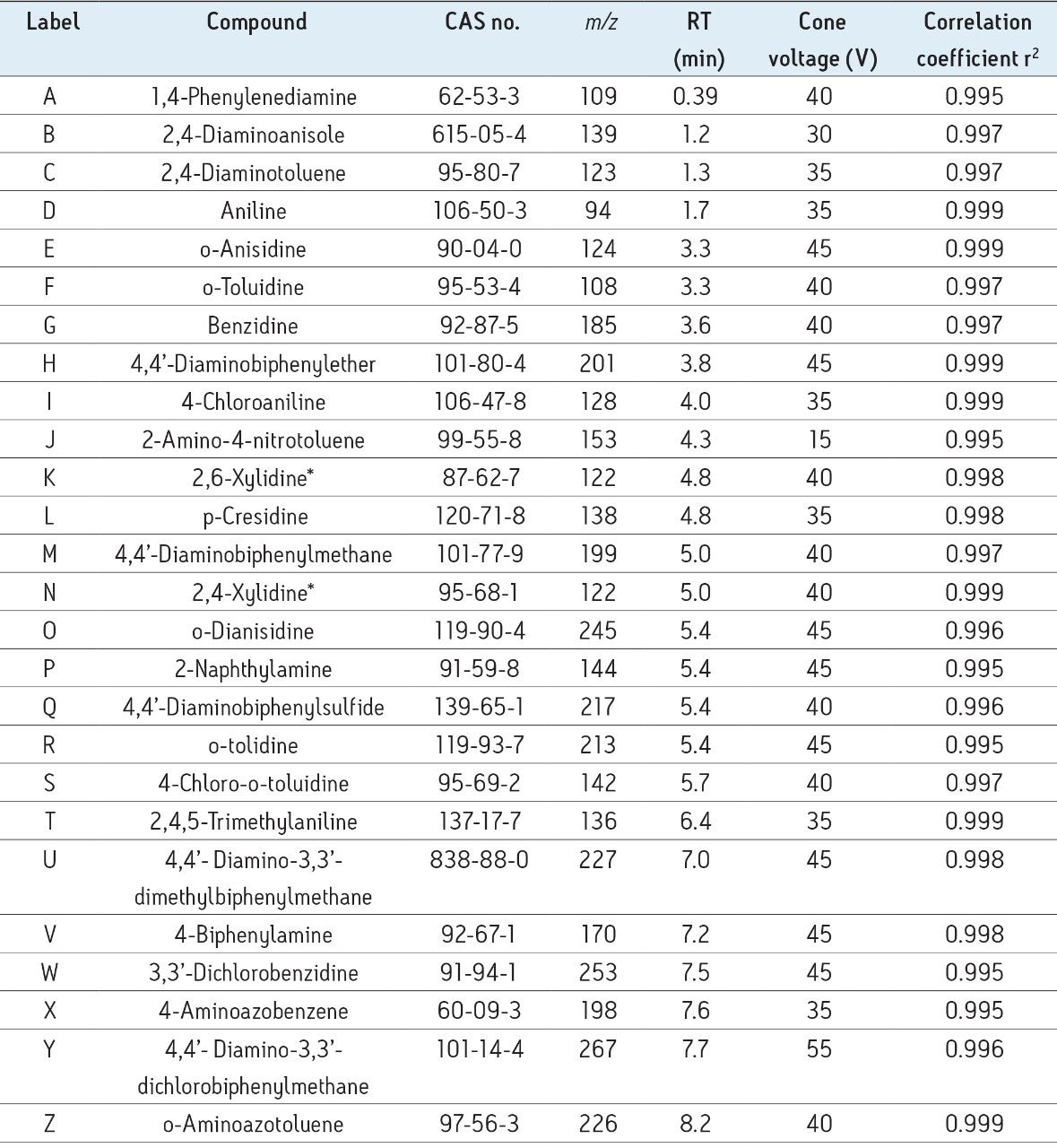

For tuning the aromatic amines using IntelliStart Technology, stock solutions of the 26 carcinogenic aromatic amines were diluted to 1 μg/mL in 50% methanol. These solutions were used to obtain tuning parameters for all amines tested. The m/z of each analyte and the cone voltages resulting from this automated tuning are provided in Table 2. A mixture of the 26 aromatic amines was separated and analyzed in 10 minutes using the ACQUITY UPLC H-Class System with SQ Detector and Empower 3 Software. The SIR chromatograms from the separation of the 26 aromatic amines are shown in Figure 1.

The chromatograms shown in Figure 1 indicate that the carcinogenic aromatic amine standards were all easily detected at 20 times below the legislative limit which is 20 mg/kg. The structural isomers 2,6-xylidine (K) and 2,4-xylidine (N) were well separated, with retention times of 4.8 and 5.0 min respectively. The identity of these isomers was confirmed with separate injections of the individual standards.

Calibration curves were obtained from 5 ng/mL to 20 μg/mL for all 26 compounds. Each standard was injected in triplicate at six different concentrations, except for 3,3’-dichlorobenzidine (5 calibration points). For each calibration curve, a linear regression and a 1/X weighting was applied. Each of these compounds showed good linearity across the range of concentrations. Retention times and correlation coefficients (r2 ) for the 26 aromatic amines are shown in Table 2.

Protocols for sample preparation to detect the aromatic amines described in EN 14362-1:20036 and EN 14362-2:20037 vary slightly depending on the nature of the sample. For this application note, cotton fabric was analyzed using a simultaneous extraction-reduction protocol.2 This extraction protocol is reported to be more efficient than the two-stage extraction procedure that is described in EN 14362-1:2003.2 For that reason, the 30 minute simultaneous extraction-reduction procedure was selected. Under the conditions of this sample preparation, o-amino azotoluene and 2-amino-4-nitro toluene are further reduced to o-toluidine and 2,4-diamino toluene, respectively. In addition, 4-aminoazobenzene generates aniline and 1,4-phenylenediamine.6,7 Therefore with this sample preparation in consideration, of the 26 analytes listed in Table 2, there are a total of 23 analytes that could potentially be detected.

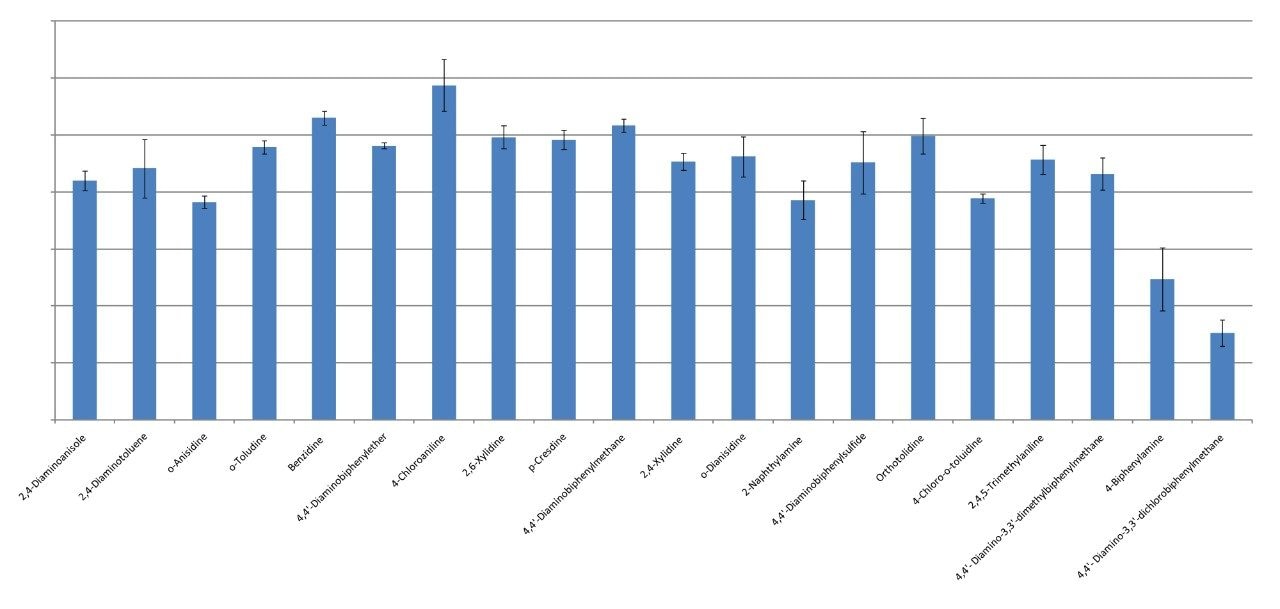

To study the extraction of aromatic amines using the method described, white cotton (not containing azo dyes and previously tested for aromatic amines) was tested after being spiked with aromatic amines at the legislated level of 20 mg/kg. Spiked and non-spiked samples were subjected to the simultaneous extraction and reduction followed by LC-MS analysis. The percentage recovery of 20 aromatic amines was calculated and is shown in Figure 2. As with the published methods there is a range of recoveries for the aromatic amines tested. The results from the current work showed an average recovery of 87.5%, ranging from 30% to 118%. Even with the lower recoveries of 4, 4’-diamino-3, 3’-dichlorobiphenylmethane the legislative requirements can still be met. Standard deviations for all compounds were less than 11%. Error bars represent mean ± standard deviations (n=3).

For these experiments, 20 out of 23 aromatic amines that can potentially be detected using this sample preparation were reported. The three that are not reported are 1,4-phenlyenediamine, aniline, and 3-3’ dichlorobenzidine. Even though 4-aminoazobenzene is reduced to 1,4-phenylenediamine and aniline using this sample preparation, their presence does not reliably ascertain the presence of colorants that generate 4- aminoazobenzene. We have therefore chosen to exclude those compounds. The third compound, 3-3’ dichlorobenzidine, was not detected in the extract following sample preparation. This compound was, however, detected when spiked into a blank extract that had been taken through the sample preparation procedure. Further development of the sample preparation procedure is required to determine the loss associated with other compounds.

A short comparison was performed to determine whether improved extraction could be achieved with the two-stage extraction procedure. For the majority of compounds it was found that the recovery was better with the single-step simultaneous extraction and reduction procedure, as reported in the literature6 (data not shown). Also in the course of experiments recoveries were found to be vastly affected with different filters. The best recoveries were achieved with Waters 0.2 μm PTFE filters.

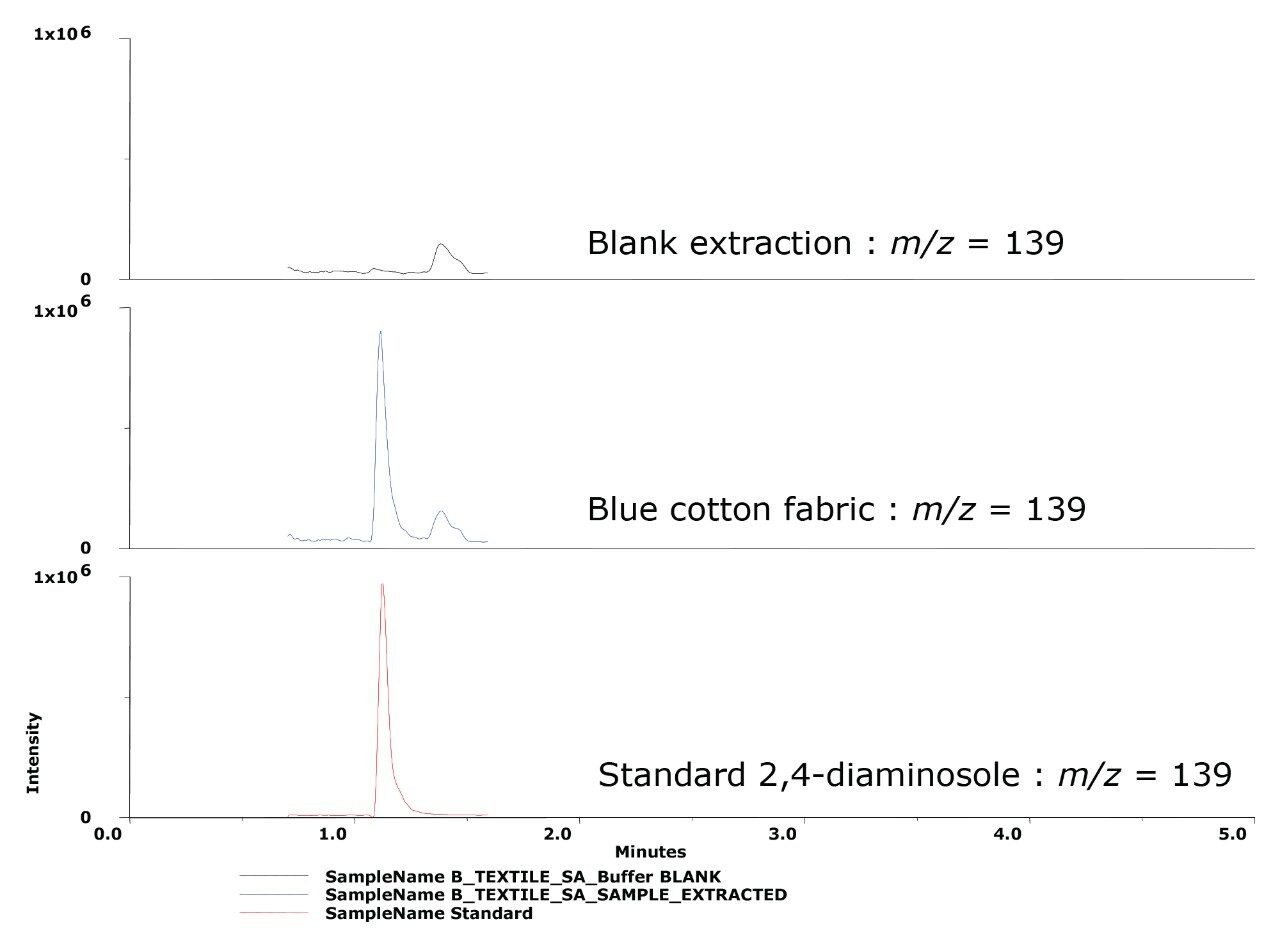

Blue-colored cotton was sourced from Africa and the dye extracted and reduced following the conditions described in sample preparation method listed on page 2. The extract was analyzed by LC-MS. A single aromatic amine (2,4-diaminosole, m/z = 139) was detected in the sample. The detected peak was quantified against the calibration curve of 2,4-diaminosole. The calculated value of the analyte in the sample was below the legislated limit. The SIR chromatograms of 2,4-diaminosole in a standard (9.76 ng/mL), the blue fabric sample and the buffer blank are shown in Figure 3.

The use of certain azo colorants cannot be reliably ascertained without additional information, such as the chemical structure of the colorants. In the case of 2,4-diaminosole, it is possible that the product from which the sample was taken may have been colored with an azo colorant structure that does not contain preformed 2,4-diaminosole but 2-amino-4-nitroanisole, which also releases 2,4-diaminosole.3,6,7

720004090, September 2011