This is an Application Brief and does not contain a detailed Experimental section.

This application brief describes the simple and rapid screening of disperse dyes in consumer products without sample preparation or chromatographic separation.

Xevo TQD with ASAP provides a rapid and easy screening method for disperse dyes.

Disperse dyes are used for coloring many synthetic fibers used in consumer products, such as polyester, nylon, synthetic velvets, and PVC.

Disperse dyes are included in the restricted substances lists (RSL) utilized by many companies to fulfill their commitment to protect the consumers of their products, their workers, as well as the community/environment.

There are legislated and non-legislated regulations and standards that detail many of the potentially sensitizing, carcinogenic, mutagenic, or toxic to reproduction disperse dyes as prohibited including: European Committee for Standardization with regard to toy safety standards (BS EN 71 part 9),1 Oeko-Tex Standard 1000,2 European Union Commission Decision (2009/567/EC),3 and the German Food and Commodities law (LFGB §30).

This study describes the simple and rapid screening of disperse dyes in consumer products without sample preparation or chromatographic separation.

Qualitative screening methods offer the chemical industry valuable time and cost savings, faster sample turnaround times, and reduced use and associated disposal of non-environmentally friendly solvents and chemicals.

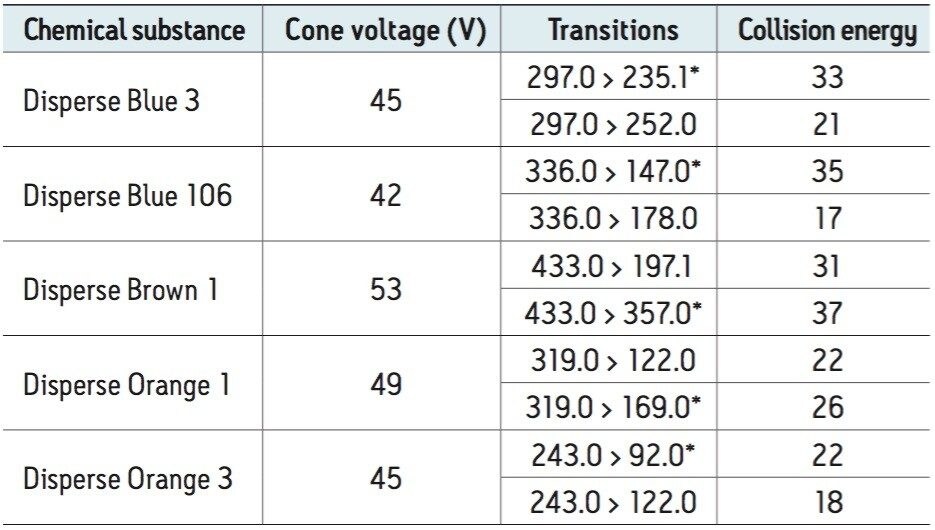

Using the Waters Atmospheric Solids Analysis Probe (ASAP) with the Xevo TQD, this study demonstrates the rapid screening of consumer products for disperse dyes by direct analysis under atmospheric pressure ionization (API) conditions, with no sample preparation or chromatographic separation. ASAP can easily and quickly be fitted to the API source in less than 2 min by replacing the current probe and fitting a corona discharge pin. Optimum MRM conditions were developed, as shown in Table 1.

0.5 g of synthetic fabric was spiked with select disperse dyes at a level of 75 µg/g (many laboratories that base their extraction protocol for disperse dyes on standard method DIN 542314 accept 75 µg/g as the practical detection limit).

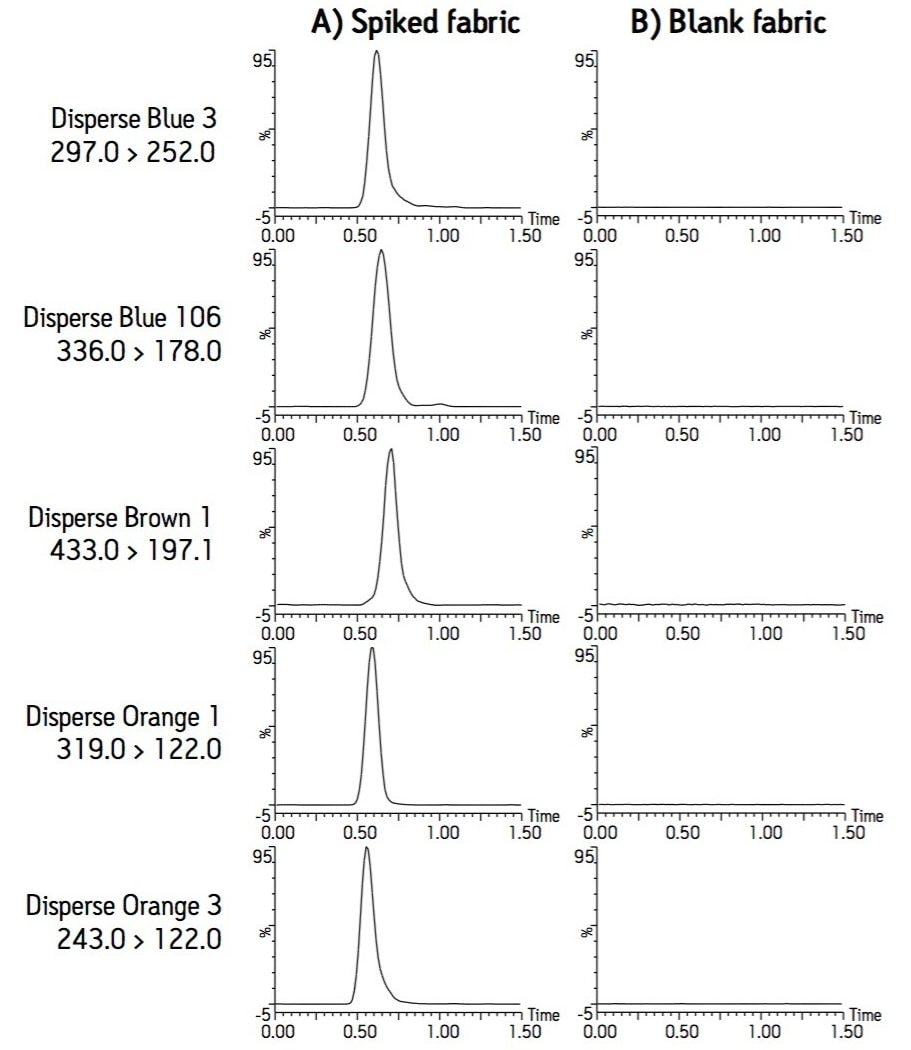

The ASAP assembly is in two parts, as seen in Figure 1, where the outer probe is continually attached to the source throughout usage; whereas, the inner probe can be removed to load the sample without compromising the source conditions. The sample was loaded by rubbing the end of a sealed glass melting point capillary tube over the fabric sample. The glass capillary, attached to the inner ASAP probe, was loaded directly into the source enclosure of the Xevo TQD. The sample was vaporized in a stream of heated nitrogen and ionized by gas phase ion/molecule reactions from a corona discharge needle. A vial of methanol was also placed in the source to act as a chemical modifier, influencing the ionization mechanism to favor the formation of protonated ions. The MRM chromatograms, revealing the desorption profiles generated from ASAP analysis on spiked fabric samples, are shown in Figure 2.

Waters Xevo TQD with ASAP can be used to provide a rapid, simple screening solution for disperse dyes in consumer products.

No sample preparation or chromatographic separation was required, resulting in a fast run time and reduced overall analysis time, offering businesses valuable productivity and consumables cost savings.

The Xevo TQD offers the ability to acquire data in MRM mode, providing improved selectivity and sensitivity to screen for disperse dyes. The system can also be rapidly switched to UPLC-MS/MS mode if quantification and confirmation of disperse dyes in consumer products is required.

720004572, January 2013