This application brief rapidly analyze artificial sweeteners in beverages and canned fruits using SPE followed by the ACQUITY UPLC H-Class System with ELSDs.

Run multiple samples in under five minutes using the ACQUITY UPLC H-Class System coupled with an ELSD.

The increase in obesity due to the consumption of sugary foods has reached epidemic levels, especially in the developed world. Food manufacturers are therefore resorting to noncaloric sweeteners to reverse this trend. Ideally, a blend of sweeteners will mimic the taste and sensation of sugar as closely as possible. Common sweeteners used today are aspartame, saccharin, acesulfame K, and sucralose. Less common substances include sodium cyclamate, NHDC (neohesperidin dihydrochalcone), and neotame. Regulations vary as to the legality of certain sweeteners in various parts of the world.

Because of the different regulations, it is desirable to have a rapid method that can be used to look for the presence of these sweeteners. Acesulfame K, saccharin, and aspartame, along with caffeine and certain preservatives, are routinely analyzed in soft drinks using UV detection. However, cyclamate and sucralose are UV transparent rendering UV detection unfeasible.

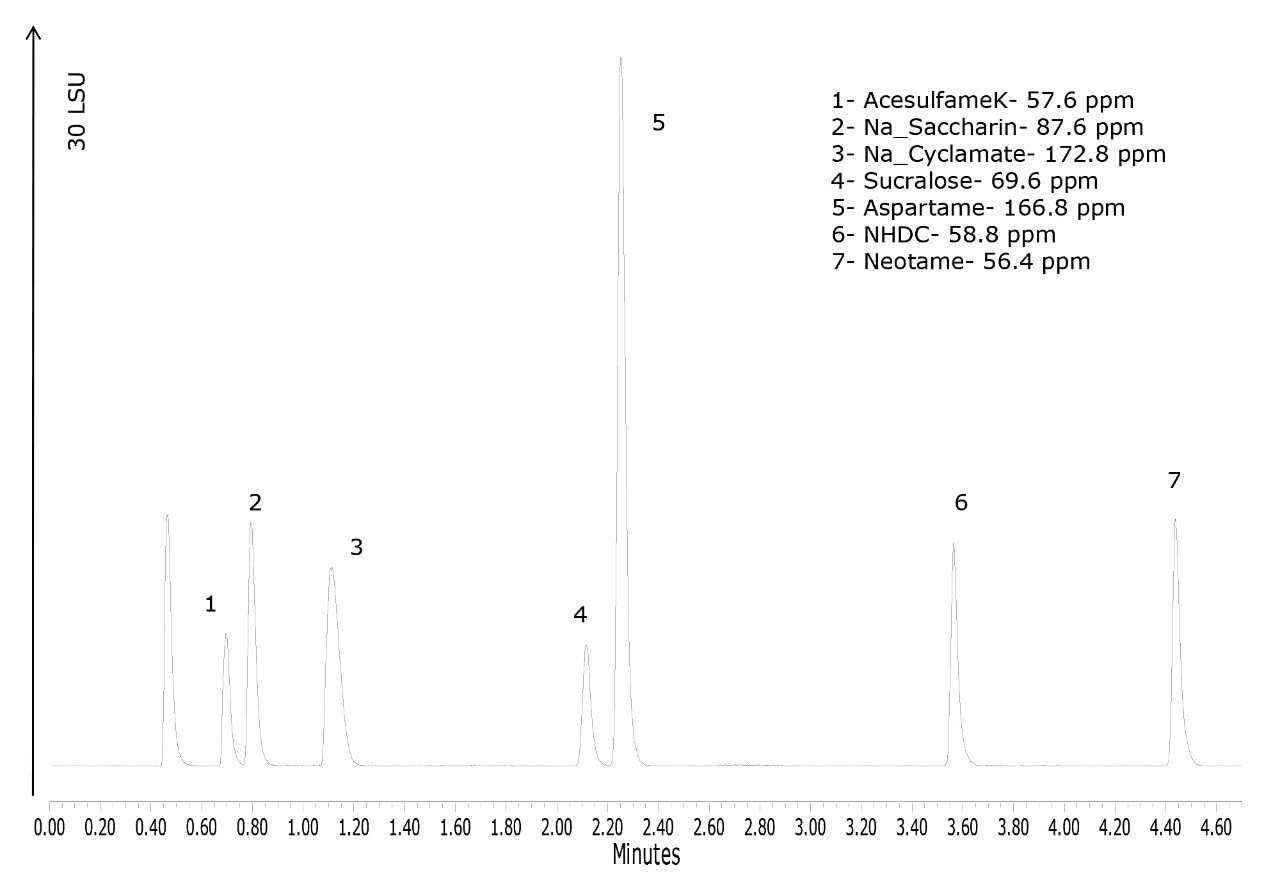

Using a Waters ACQUITY UPLC H-Class System equipped with an Evaporative Light Scattering Detector (ELSD), separation of the seven listed analytes can be achieved in less than five minutes, as shown in Figure 1. This method uses UPLC HSS T3 Column chemistry and a ternary gradient. A calibration curve using a log linear fit is employed for quantification. This procedure can also be used for qualitative screening.

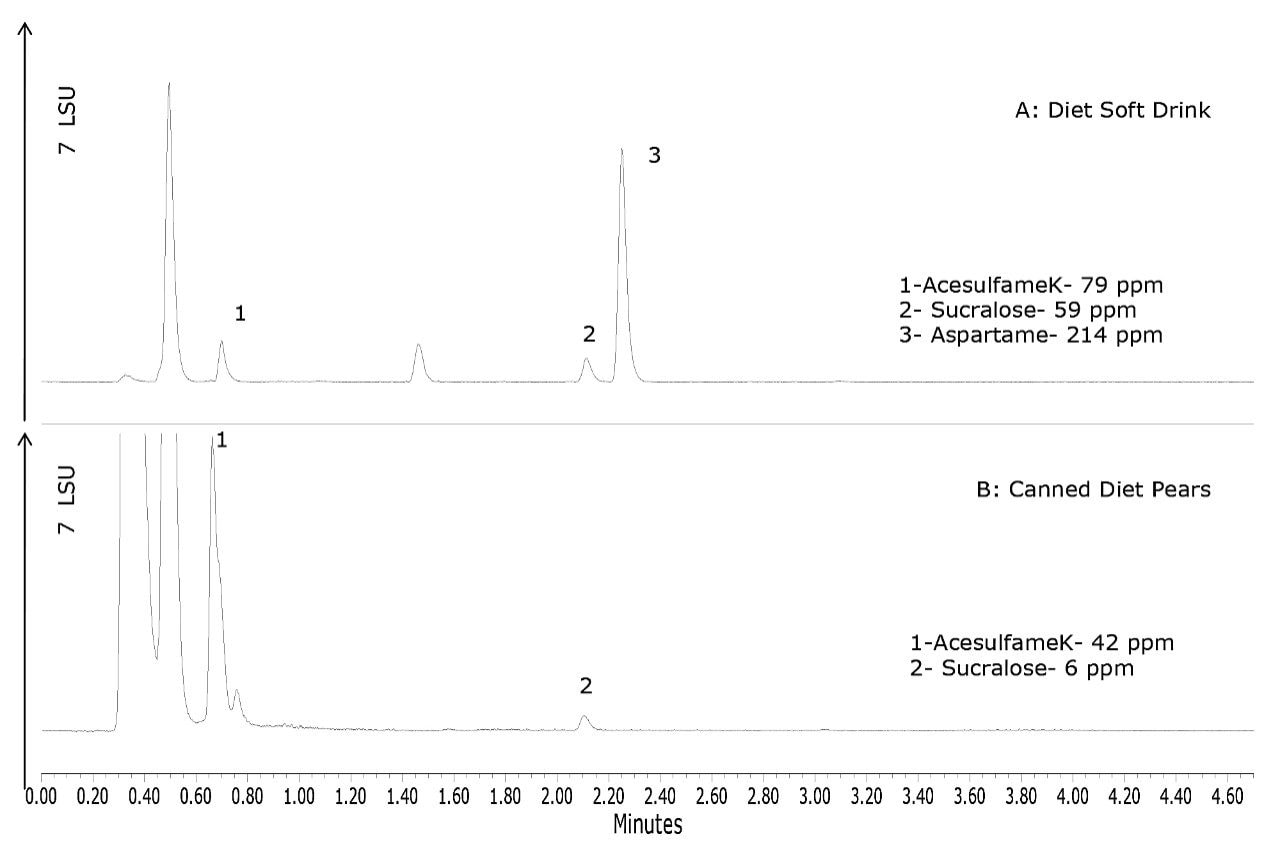

For simple beverage samples, filtration and, if necessary, degassing to remove carbonation can be employed prior to direct injection of the samples. For more complicated matrices, a simple cleanup using Sep-Pak C18 Cartridge can be used for sample preparation. This procedure is described in the European Commission’s validated method for the analysis of nine sweeteners (EUR 22727 EN, A. Wasik and M. Buchgraber, 2007). The sample, canned fruit in this example, was homogenized and thoroughly mixed with a buffer solution, then centrifuged. The supernatant was loaded onto a Sep-Pak C18 Cartridge, washed, and the analytes eluted with methanol. Chromatograms from a diet soft drink and canned diet pears carried through this procedure is shown in Figure 3. Three of the sweeteners were identified and quantified in the soft drink and two were identified and quantified in the canned pear sample.

Using the ACQUITY UPLC H-Class System with ELSD detection, baseline separation of seven sweeteners can be achieved in less than five minutes. The short run time allows many samples to be run either for screening purposes, or as a quantitative QC check.

720004166, November 2011