This is an Application Brief and does not contain a detailed Experimental section.

Achieving successful method transfers between instruments can be very challenging without the appropriate tools. Waters Automated Method Development System (AMDS) can be a useful tool to assist in method transfers between instruments of different designs.

Waters AMDS proves as an excellent tool to transfer methods efficiently while ultimately saving time and money.

HPLC vendor designs can dramatically impact how a method performs during the transfer process. For example, if a developed method contains components that are susceptible to selectivity changes with slight changes in temperature, the success rate for transferring that method to another instrument will be slim.

Presently there are two common designs for column heaters: one utilizes a design based on contact with heat plates, which allow precise temperature measurements; the other – upon which Waters HPLC instruments are based – is based on convection oven engineering. The convection oven design allows measurements that are not just precise, but accurate.

As will be seen, transferring methods with column heater design differences poses a challenge. Waters Automated Method Development System (AMDS) can be a useful tool to assist in method transfers between instruments of different designs. AMDS not only reduces the effort involved – it can help identify and troubleshoot any problems.

Manufacturers built many instruments that in the past that have used, or currently use, a contact heat plate. It is an effective way to heat a column, but there are some issues with their use in an analytical HPLC environment. Heat plates may have gaps and cold spots that can lead to inconsistent temperatures throughout the heating compartment. Temperature probes illustrate that the temperature can range up to ±4 °C along the length of a column on these heat plates. Such designs are precise, but not accurate. Variations of ±4 °C on methods with temperature-dependant selectivity can be extremely difficult to transfer. Unfortunately, these column temperature range variations can cause issues when upgrading to newer technology.

A column heater with a convection oven design allows for minimal temperature variations within the compartment. Temperature probe readings verify that the temperature is not only precise, but also accurate. Waters AMDS Alliance Systems have adopted this design for column heating. The superior design allows for more accurate results and more robust methods. However, transferring methods developed on other manufacturers’ instruments to an Alliance System can still be difficult without the right tools. AMDS provides these necessary tools to transfer and improve reversed-phase methods.

With the help of simulation software such as Drylab 2000plus and an automated process provided by AMDS through Empower Software and an Alliance System, we can predict chromatographic conditions necessary to match chromatographic separations performed on other instruments in an efficient, unattended manner.

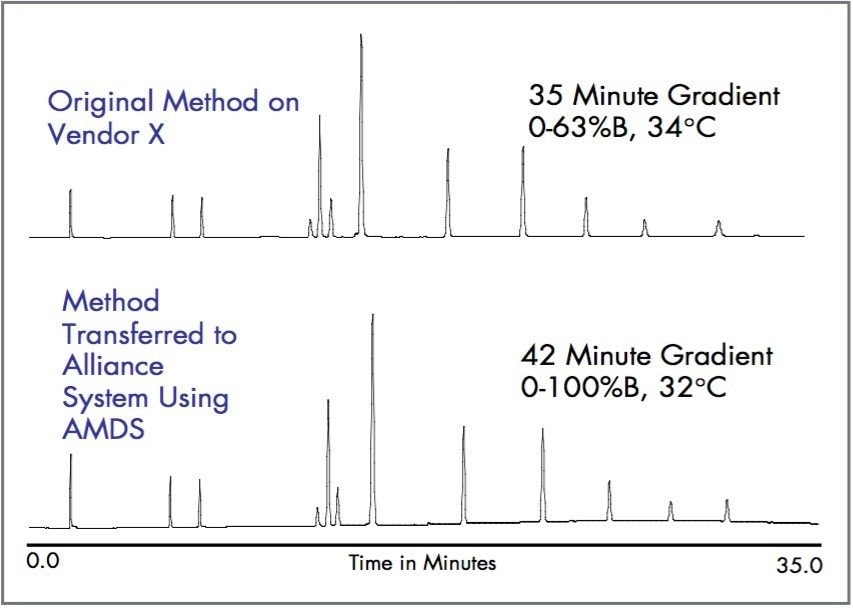

Using the method transfer capabilities of the Waters Automated Method Development System, temperature selectivity issues are modeled and easily recognized. As shown in Figure 1, the original method was developed on an instrument (Vendor X) known to use heat plate technology. The Waters Alliance System to which it was transferred uses convection oven engineering. Once the automated calibration experiments were performed and automatically entered into Drylab 2000plus, a chromatographic match was achieved by just the simple manipulation of the Drylab Resolution Plot (Figure 2).

In this example, moving the cursor to various places within the colorful resolution plot within Drylab2000 reveals the temperature robustness areas needed to transfer this method. A temperature robustness area is an area on the colorful Drylab2000 resolution plot that is in the middle of a color that would resist small changes in resolution when changing temperature. (See Figure 2). Improving this method can be achieved just as easily by identifying an area within the middle of a color region such that minimal changes in temperature (or the organic mobile phase) will not change resolution or selectivity significantly.

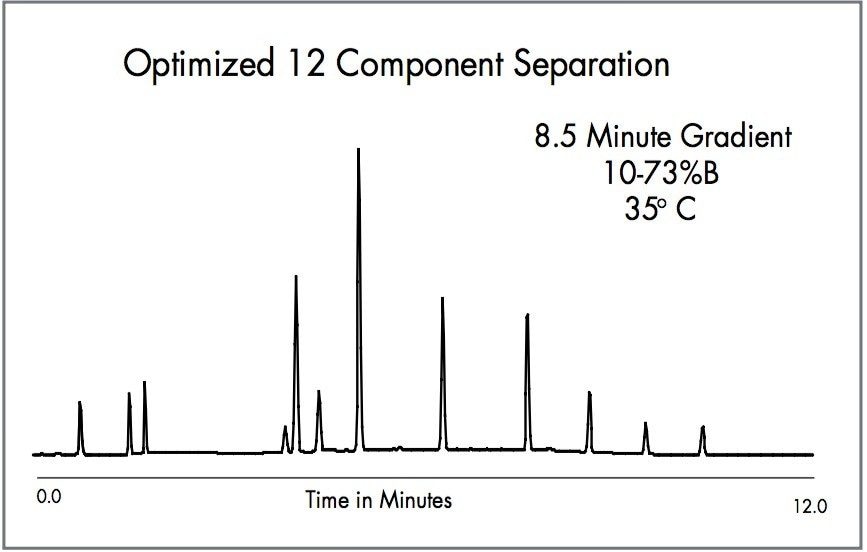

Further manipulations within Drylab’s Gradient Editor also assisted with transferring the method between these systems, which had exhibited varying gradient proportioning ratios. Other features within the gradient editor also allow the user to perform simulations to achieve shorter run times that meet a user’s goals (Figure 3). A user can also simulate multiple gradient points such to manipulate the chromatogram to save time.

Achieving successful method transfers between instruments can be very challenging without the appropriate tools. Recognizing the source of the issue is always the first step to method transfer success; AMDS can be the facilitator for recognizing these hidden issues.

Transfering methods with temperature selectivity issues are easily addressed by a colorful resolution plot that illustrates robust regions. A gradient editor helps with finding mixing differences between transfers from different manufacturers’ instrumentation at the click of a button. The chemist is also given the option of a more robust, faster, or even a different approach such as isocratic possibilities that were not apparent during the original development of the method.

The use of all these tools within Waters AMDS proves as an excellent tool to transfer methods efficiently while ultimately saving time and money.

720000827, April 2004