This application note describes SEC analysis of starch on the Alliance GPCV2000 System with the Precision Detector 2040 laser light scattering detector.

Starch forms a major part of the plant food supply for the world population and is an important ingredient for the processed food industry.1 Its functionality and structure are used to improve the nutrition and texture of foods, which makes the analysis, modification and further analysis of starch important. Starches are also used in other industrial products, such as cosmetics, plastics, and absorbents. Size exclusion chromatography (SEC) is the primary analytical tool to obtain molecular weight information for starches.2 The SEC analysis is usually conducted in dimethyl sulfoxide (DMSO), or a DMSO/water mixture. When coupled with on-line viscometer and laser light scattering detectors, SEC can also provide branching and molecular dimension information. The Waters Alliance GPCV2000 is often used in QA/QC labs for routine analyses and in R&D labs or academia as a research tool. This note describes SEC analysis of starch on the Alliance GPCV2000 System with the Precision Detector 2040 laser light scattering detector.

|

Systems: |

Waters Alliance GPCV2000 (RI and Viscometer) with PDI 2040 dual angle laser light scattering detector. |

|

Software: |

Waters Alliance GPC2000 v. 2.0 was used for instrument control and Waters Empower with GPC, GPCV, and LS options was used for data processing. |

|

Flow rate: |

0.52 mL/min |

|

Injection volume: |

106.5 µL |

|

Temperatures: |

70 °C(carousel, injector, detector) |

|

Mobile phase: |

Dimethyl sulfoxide (DMSO) and water (Millipore)(90/10 v/v) with 0.1% (w/v) NaNO3. Mobile phase was filtered with 0.5 micron filter membrane. |

|

Column set: |

One Waters Styragel HT 2 DMF (WAT054480) and one Styragel HT 6E DMF (WAT044220) (7.8 mm x 300 mm). |

|

Sample prep: |

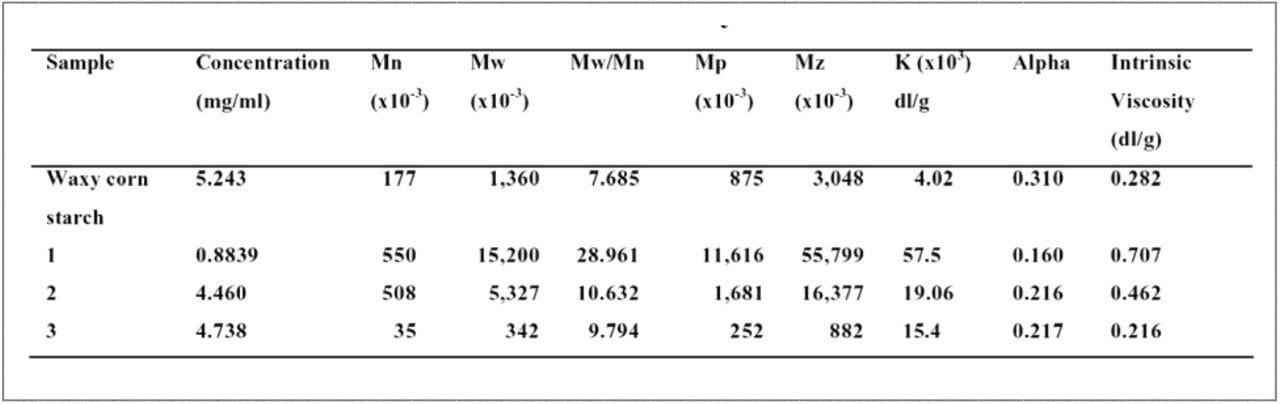

All starch samples are hydrolyzed corn starch obtained from a starch manufacturer. Polymer solutions were prepared by weighing the starch in glass containers, adding the desired amount of solvent, stirring overnight for dissolution, and standing for 6 days until injected. The same GPC solvent was used for Pullulan standard solutions. Samples concentrations are in Table 1. |

|

Light scattering: |

The estimated refractive index for the solvent mixture at 70 °C is 1.44. This value is based on the densities and refractive indices of DMSO and water at 20 °C, and is extrapolated to 70 °C. The light scattering detector was calibrated with Pullulan standards. The estimated specific refractive index increment of Pullulan standards is 0.068 mL/g. The same value was used for the starch samples. |

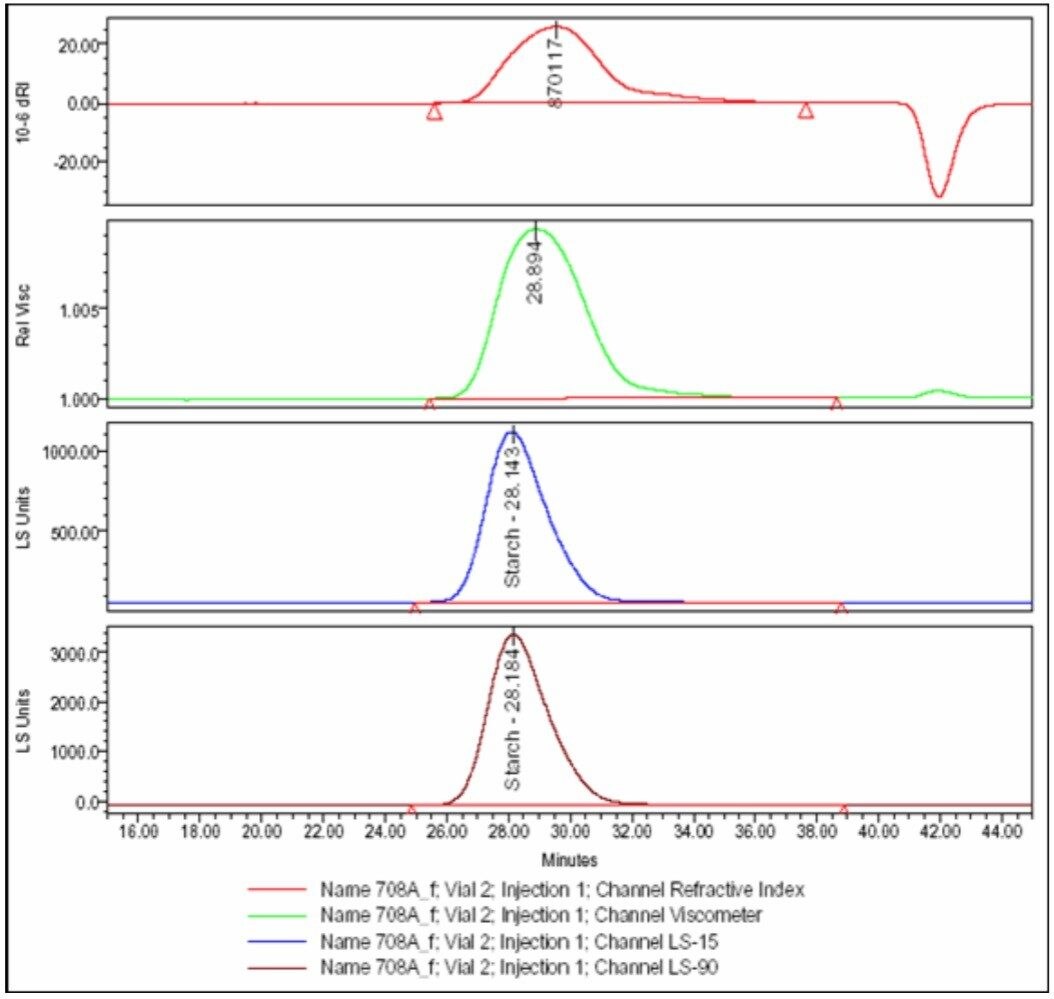

Initial chromatography for Sample 1 indicated a molecular weight of such magnitude that its light scattering signal went beyond the upper limit of the detector scale. The concentration of this sample was then decreased by a factor of five (to about 1 mg/mL) and rerun. Satisfactory responses were obtained in all detectors (chromatogram not shown). Typical chromatograms of the starch samples from RI, viscometry, and light scattering detectors are in Figure 1. The results are summarized in Table 1.

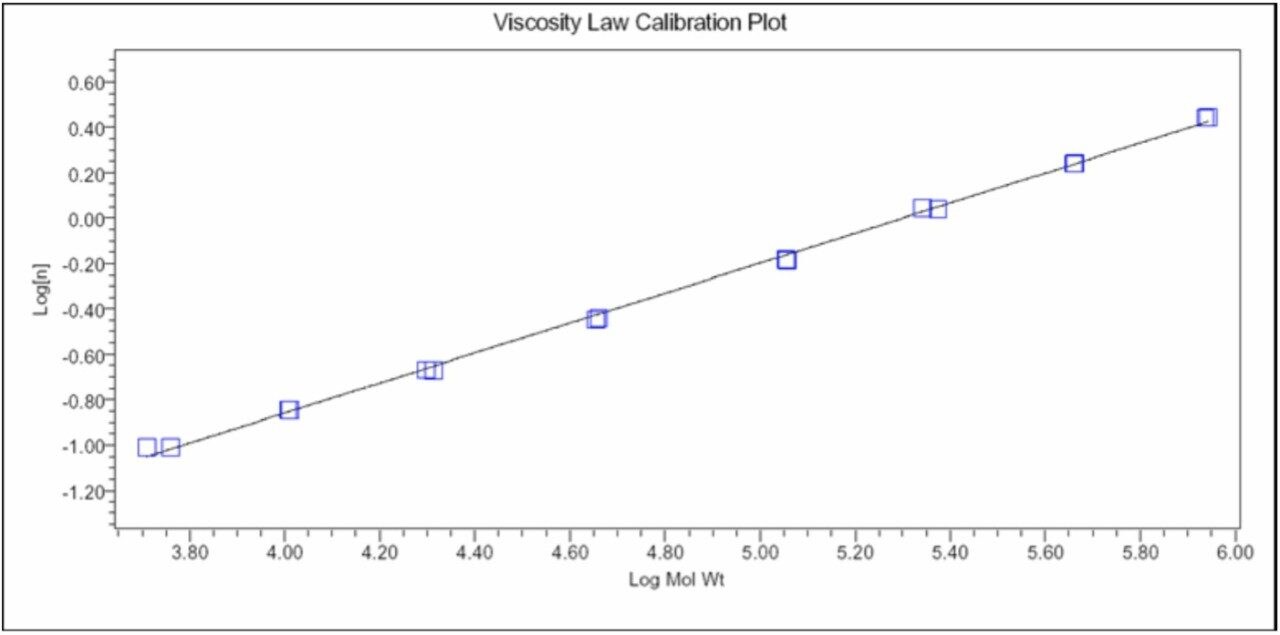

Pullulan is a linear polysaccharide often used as a GPC standard to create molecular weight calibration curves. A series of Pullulan standards were measured in this study, not to create a calibration curve, but to establish the Mark-Houwink equation for linear polysaccharides. The Mark-Houwink equation obtained has constants K and α equal 3.15 x10-4 dL/g and 0.66, respectively (Figure 2). The α value agrees with literature values for Pullulan in similar solvents.3

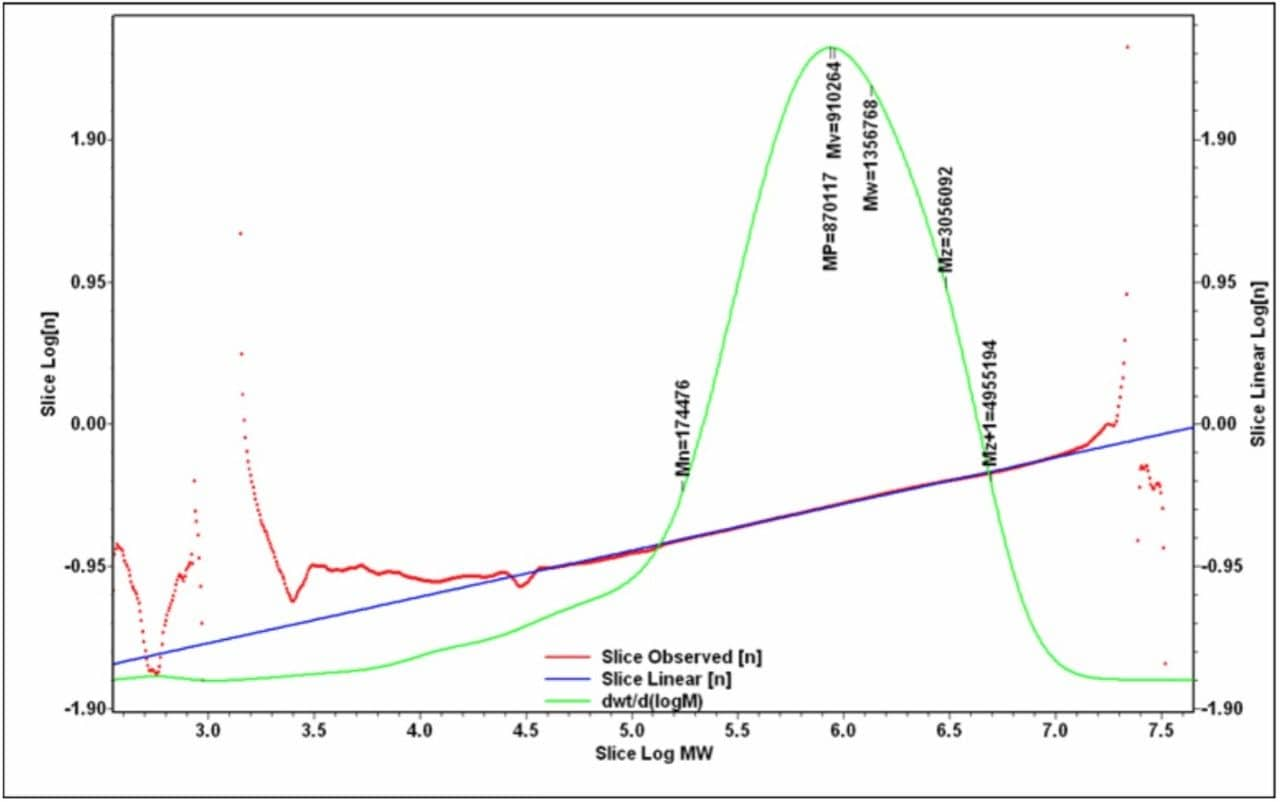

Corn starch usually consists of linear and branched polysaccharides. Waxy corn is a special corn that contains 100% branched polysaccharide (amylopectin). Hydrolyzed starch from waxy corn was analyzed to determine the Mark-Houwink constants for branched polysaccharide. The log-log plot of slice intrinsic viscosity and slice molecular weight for hydrolyzed starch from waxy corn is in Figure 3. The fitted Mark-Houwink equation has an avalue of 0.31. Usually for linear molecules in good solvents, α is in the range of 0.6 to 0.8. Branched molecules tend to have lower α values. The α value of waxy corn starch confirmed that it has a highly branched molecular structure.

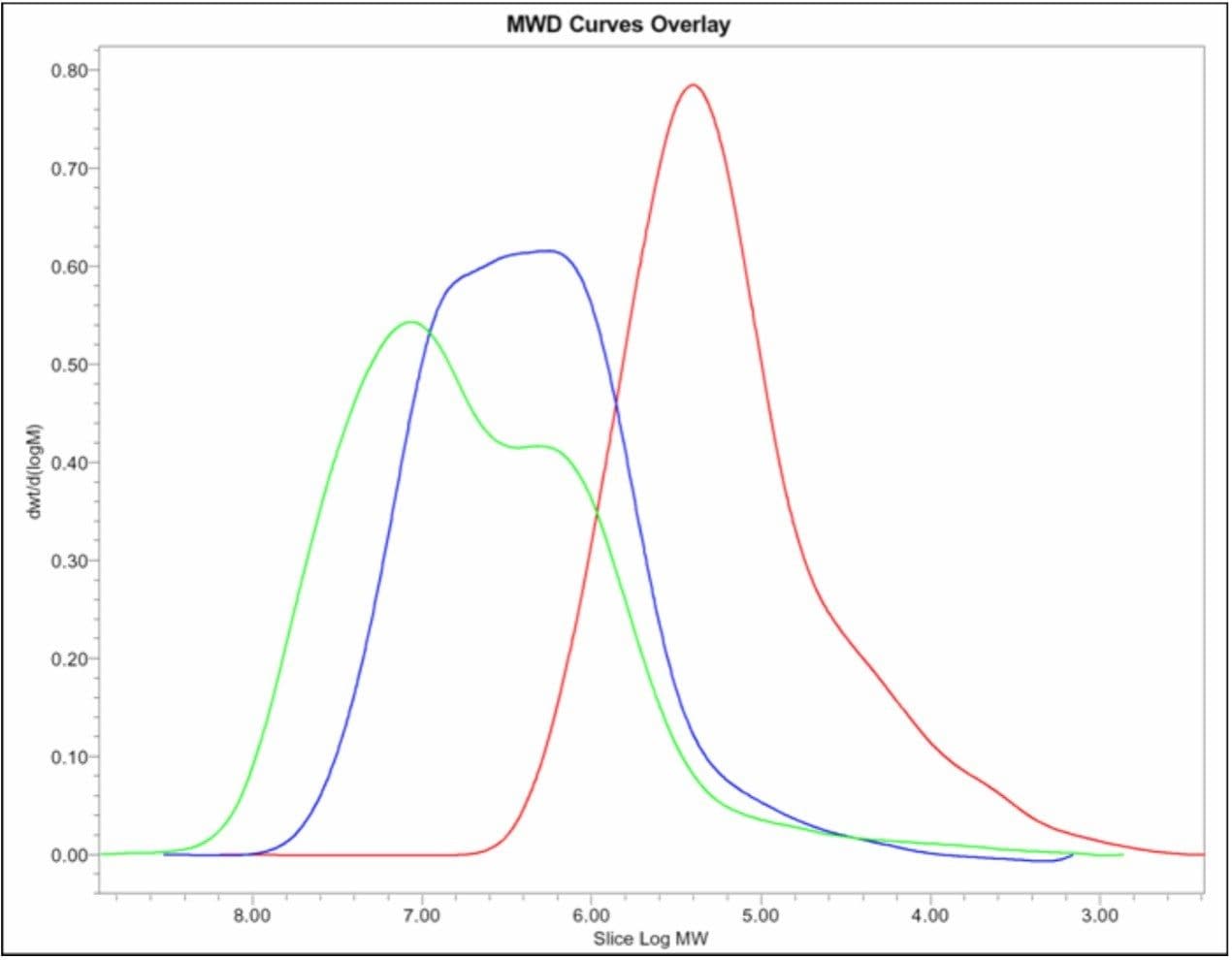

Starch samples with various degrees of hydrolysis were analyzed to monitor the effect of hydrolysis on the molecular weight of resulting starch. Hydrolysis causes large starch molecules to decompose into smaller molecules, and results in lower molecular weight. Typically, the intrinsic viscosity decreases with the increased degree of hydrolysis. Figure 4 is an overlay of molecular weight distributions of the starch samples. Samples 2, 3, and 4 are hydrolyzed starch samples with increasing degrees of hydrolysis.

The data in Figure 4 show that the more the starch is hydrolyzed, the lower the resulting molecular weight. Also, the intrinsic viscosities decreased with the increase in hydrolysis.

The decrease in molecular weight and intrinsic viscosity of hydrolyzed starches can be easily monitored using the GPCV2000. Empower Software enables automatic calculation of these values for easy reporting and product comparisons. Mark-Houwink equations of linear and branched polysaccharides were obtained from the measurement of the Pullulan standards and one waxy corn starch sample. The a value of the branched polysaccharide is much lower than the linear polysaccharide (Pullulan), which confirms a highly branched molecular structure. Hydrolysis of starch samples yields lower molecular weight and lower intrinsic viscosity. This application has utility in any industry concerned with the hydrolysis of starch.

720001379, September 2005