This is an Application Brief and does not contain a detailed Experimental section.

In this application brief, two active solvent preheater (APH) designs are compared to demonstrate the impact on chromatographic performance and the analytical transfer of methods.

Usability and robustness is enhanced through continuous product improvement while providing equivalent chromatographic performance.

Throughout the lifetime of liquid chromatography instrumentation, many changes and improvements will be made to instrument design to improve performance, robustness, ease-of-use, or a combination of these attributes. However, it is critical that any established methods can be seamlessly transferred from existing instrumentation to the improved instrument design. In this example, two active solvent preheater (APH) designs are compared to demonstrate the impact on chromatographic performance and the analytical transfer of methods.

ACQUITY UPLC System OQ/PQ Test Solution #11 containing 4 μg/mL of 2-acetylfuran, acetanilide, acetophenone, propiophenone, benzophenone, valerophenone, and butyl paraben.

|

System: |

ACQUITY UPLC I-Class PLUS, configured with a CH-A (Column Heater) and ACQUITY TUV with 5 mm Flow Cell |

|

Column: |

ACQUITY UPLC BEH C18, 130Å, 1.7 μm, 2.1 × 50 mm, (p/n: 186002350) |

|

Column temp.: |

Varied |

|

Injection volume: |

5 μL |

|

Flow rate: |

0.600 mL/min |

|

Mobile phase A: |

Milli-Q water |

|

Mobile phase B: |

Acetonitrile |

|

Gradient: |

Linear gradient of 10 to 90% B over 3 minutes |

|

Data Management |

Empower 3, FR2 |

Column temperature and solvent preheating play a critical role in liquid chromatography.1 When manipulated, column temperature can affect both retention and selectivity. In fact, small changes in column temperature can be readily seen in the resulting retention times (Figure 1). Note that later eluting peaks show a larger retention time shift under the differing temperatures.

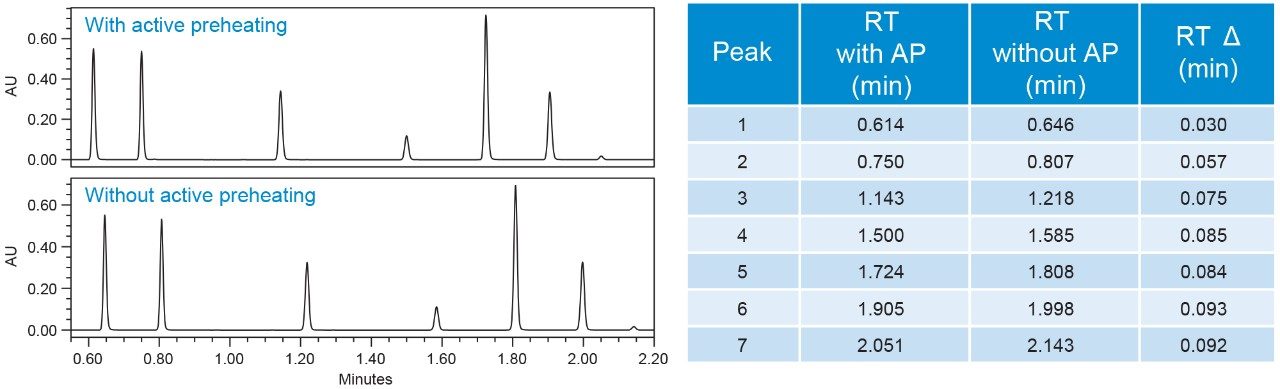

For these reasons, it is important that column temperature is well controlled during an analysis. However, in addition to a controlled thermal environment to host the separation column, it is equally important to ensure the mobile phase is properly heated prior to entering the column. Lack of solvent preheating will affect peak shape as well as retention time and retention time reproducibility. Figure 2 shows the effects of preheating the solvent versus not preheating the solvent prior to entering the column on peak retention times.

In addition to potential effects on retention time and peak shape, the lack of solvent preheating can also negatively impact retention time reproducibility for replicate injections. Due to the potential impact solvent preheating has on chromatographic performance, maintaining the thermal properties when investigating design alternatives is critical to monitor. This critical performance attribute was of utmost importance when investigating APH design improvements as part of the development of the ACQUITY UPLC I-Class PLUS System.

In addition to thermal performance, other usability features were designed into the product which includes a new high pressure, finger-tight fitting. This new fitting incorporates novel features to ensure that column connections are reliable and robust, as well as minimize the potential for leaks and dead volume which can negatively impact chromatographic performance. Collectively, these design changes provide an enhanced, worry-free, user experience by increasing the robustness of the active preheater without imparting any impact on developed methods.

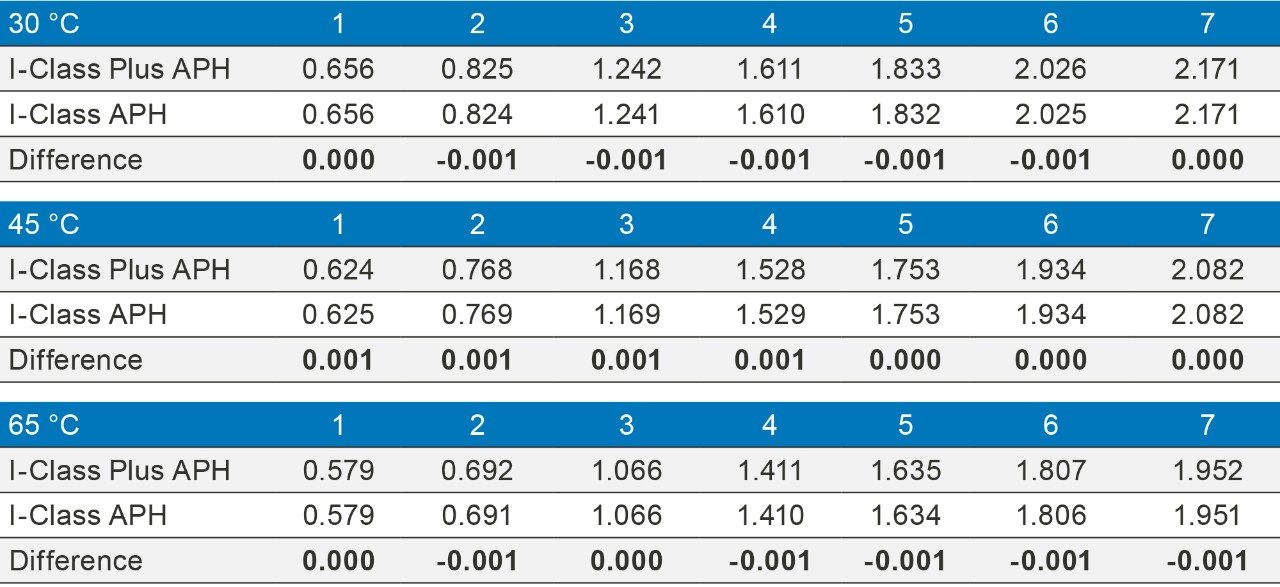

To show consistency of chromatographic performance between the ACQUITY UPLC I-Class and I-Class PLUS APH designs, a mixture of 7 compounds was injected (8 replicates) at various column and APH temperature intervals, specifically 30, 45, and 65 °C. Because small changes in temperature can be seen in the retention time of eluting compounds, the resulting component retention times were compared between the two active preheater designs to assess any potential differences in heating behavior. The average retention time of the 7 component peaks over 8 replicate injections using both preheater designs is reported in Table 1.

The maximum difference between the average retention times was 0.001 minutes, which is well within the standard deviation of the eight replicates, providing evidence that the heating behavior is the same between the two active preheater designs.

Chromatographic performance has been proven to be consistent and repeatable when comparing ACQUITY UPLC I-Class and I-Class PLUS active preheater designs, while enhancing ease-of-use and ensuring more robust column connections.

720006236, March 2018