This is an Application Brief and does not contain a detailed Experimental section.

This application brief demonstrates the benefits of using QuanRecovery Vials for trace analysis of fatty acids in RPLC-MS based workflows.

Incorporation of QuanRecovery vials in sample preparation procedures can improve recovery of target analytes at trace levels in solution.

Free Fatty Acid (FFA) analysis is commonly performed in industry and academics as a part of raw material assessment, impurity profiling, QC/QA testing, as well as lipidomic research. Except for raw material assessment, many of these analyses are limited by available sample and assay sensitivity when targeting low-abundant species. This can present a challenge during sample preparation as excessive sample handling can lead to diminished recovery of trace analytes due to non-specific adsorption to surfaces in contact with the sample, which adversely impact assay sensitivity and reproducibility. This is particularly evident when dealing with glass surfaces of sample vials where exposed silanol groups can irreversibly adsorb samples. Strategies to overcome non-specific adsorption included pre-conditioning of glass surfaces in contact with the sample to “passivate” active adsorption sites as well as using material that exhibits low adsorption characteristics. While effective, the former approach adds to sample preparation time and can be labor intensive. As demand for productivity and higher throughput continues to rise, the need for high performance surfaces that can deliver consistent results “out-of-the-box” is becoming more evident.

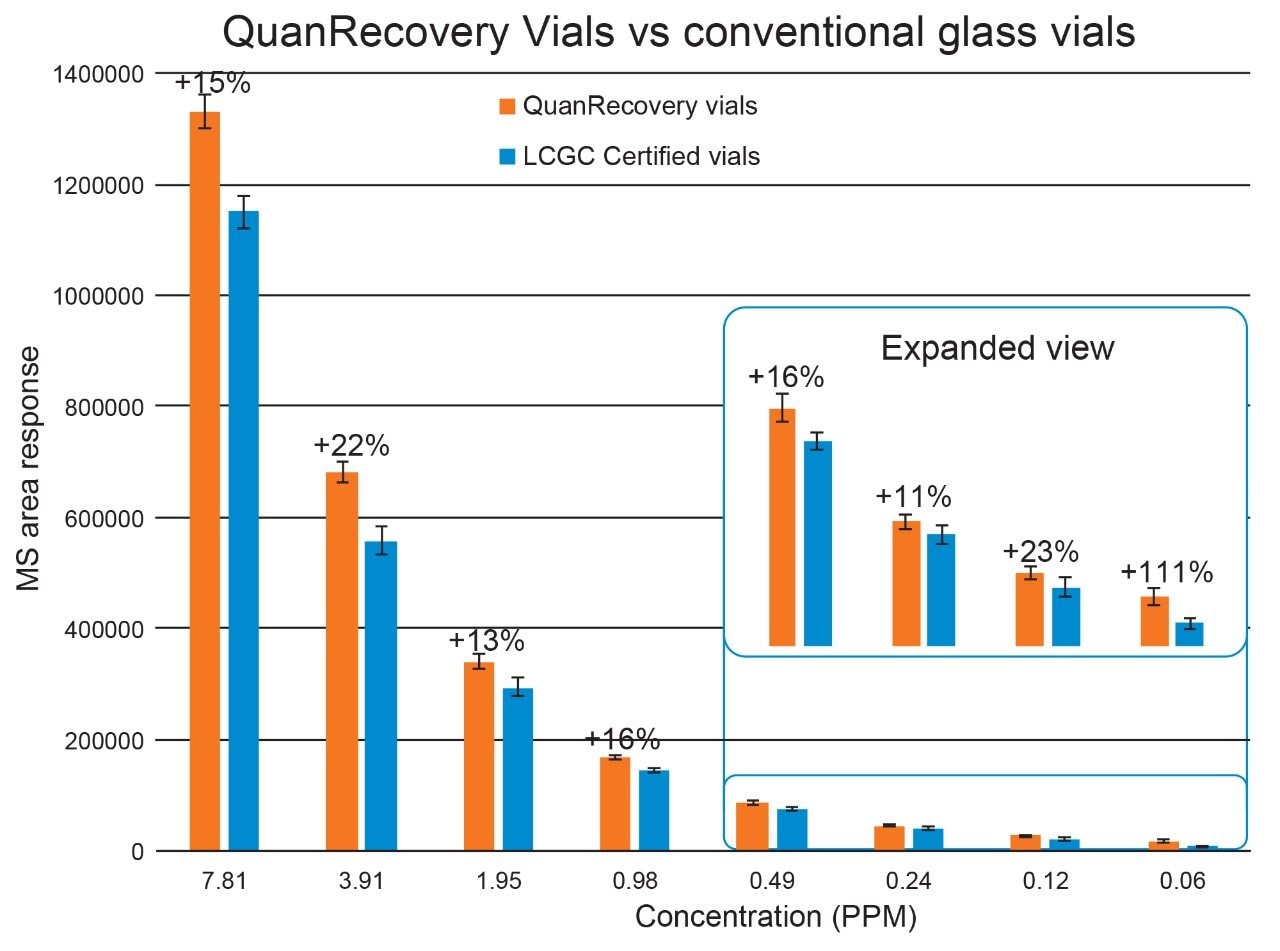

MaxPeak High Performance Surfaces is a solution designed to increase analyte recovery, sensitivity, and reproducibility by minimizing analyte/surface interactions that can lead to sample losses (see Waters literature 720006571EN). As a part of the MaxPeak product line, QuanRecovery Vials and Plates were designed to minimize sample losses by limiting non-specific binding and ionic interactions without the need of blocking agents or sample derivatization. To demonstrate the performance of QuanRecovery Vials, a dilution series of a free fatty acid (lauric acid, C12:0, MW:200.31 g/mol) was performed and compared against LCGC Certified glass vials. To facilitate the comparison, a stock dilution series was prepared after which 300 μL of each dilution was then aliquoted into both the LCGC Certified glass vials (p/n: 186000307C) and the QuanRecovery Vials (p/n: 176004434), and vortexed. Analysis was performed using a preoptimized LC-MS method for fatty acid analysis on an ACQUITY UPLC H-Class PLUS Bio with an ACQUITY QDa Mass Detector using SIR for quantitation. Sample dilution points from 7.81 ppm to 0.06 ppm were chosen to evaluate trace level detection for both vial types. Triplicate injections were used to evaluate standard deviation and averages for each dilution point for both vial types. Resulting free fatty acid chromatograms showed that QuanRecovery Vials consistently exhibited higher recovery when compared against LCGC certified glass vials. As shown in Figure 1, analyte recovery was improved between 11%–111% with a mean detector response increase of 17% (excluding outliers) when using QuanRecovery Vials. These observations illustrate the importance of vial selection in the recovery and analysis of trace level fatty acid analytes.

With the growing implementation of LC-MS-based methods, selection of vials can have an impact on analysis of analytes at trace levels. Traditional glass surfaces suffer from non-specific loss at the trace level, while treated plastic surfaces do not. QuanRecovery Vials and Plates have recently been introduced as a part of the MaxPeak High Performance Surface products to ensure high sample recovery without comprising productivity. This work demonstrates the benefits of using QuanRecovery Vials for improved trace level analysis of FFAs in LC-MS workflows.

720006644, August 2019