This is an Application Brief and does not contain a detailed Experimental section.

This application brief demonstrates to selectively analyze 36 disperse, basic, acid, solvent and direct synthetic dyes to below EU legislative limits.

Reduce analysis times from 17 min to <5 min.

Synthetic dyes are classified according to how they are used in the dyeing process. For example, disperse dyes which are mostly azo- or anthraquinone compounds are generally used for dyeing synthetic textile materials such as polyester, nylon, and PVC. The type of bonds formed between the dyes and the fabric, determine the properties of the dyes. For example, disperse dyes are not chemically bonded to the fibers of the textile, thus they can easily migrate onto the skin of the person wearing the garment, especially if the textile fastness is poor.

A number of synthetic dyes are known to be allergenic when they come into contact with human skin or if they are are classified as potentially sensitizing, carcinogenic, mutagenic, or toxic to reproduction. 20 known allergenic dyes are listed by the Oeko-tek Standard 100 and the permitted limit is <50 mg/kg. Other legislation such as European Union (EU) 2009/567/EC has banned the use of these sensitizing dyes.

The standard method for the analysis of disperse dyes in textile products and components is DIN 54231-2005 using HPLC-UV-MS with an analysis time of 17 minutes.

For synthetic dyes that have very similar UV olvent, and direct dyes. absorbance maxima, it can be challenging to correctly identify their presence. Whereas, for the dyes considered that have different molecular weights, utilizing mass spectrometry can provide more selectivity and confidence in their identification.

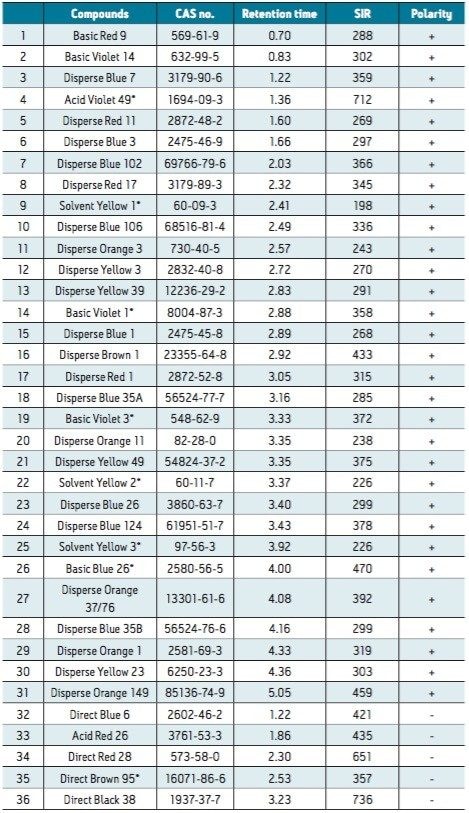

The Waters ACQUITY UPLC H-Class System with the ACQUITY QDa Detector was used to monitor a total of 36 disperse, basic, acid, solvent, and direct dyes including 28 dyes listed in the Oeko-Tex Standard 100 and 2009/567/EC. The list of the synthetic dyes considered are provided in Table 1.

The time required for method development was greatly reduced using the pre-optimized source parameters in the ACQUITY QDa Detector, where the required sensitivity were achieved in both polarities for both positive and negative ionizing dyes. The low system dispersion in the ACQUITY UPLC H-Class System and the use of sub-2-μm particle columns also greatly increased peak resolution and enhanced sensitivity. Here, two methods were developed for both positive and negative ionizing dyes with analysis time of 5 and 4 minutes respectively.

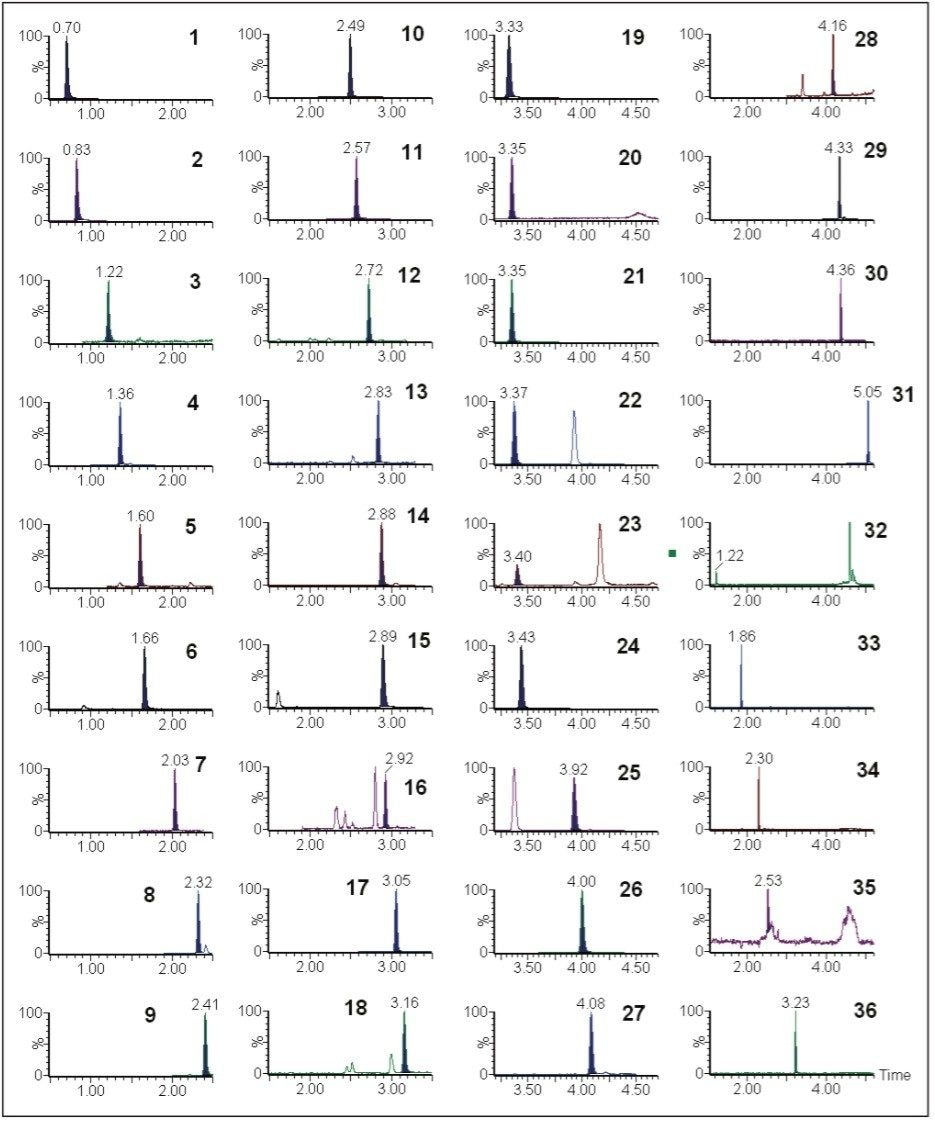

Dyes were monitored according to their respective retention time, ionizing polarity, and Single Ion Recording (SIR) mass-to-charge ratio (m/z), as described in Table 1. In the highly regulated inks and dyes industry, SIR provides more selectivity and sensitivity compared to HPLC-UV analysis. The SIR chromatograms, shown in Figure 1, indicate that synthetic dyes can be easily and confidently detected at low levels.

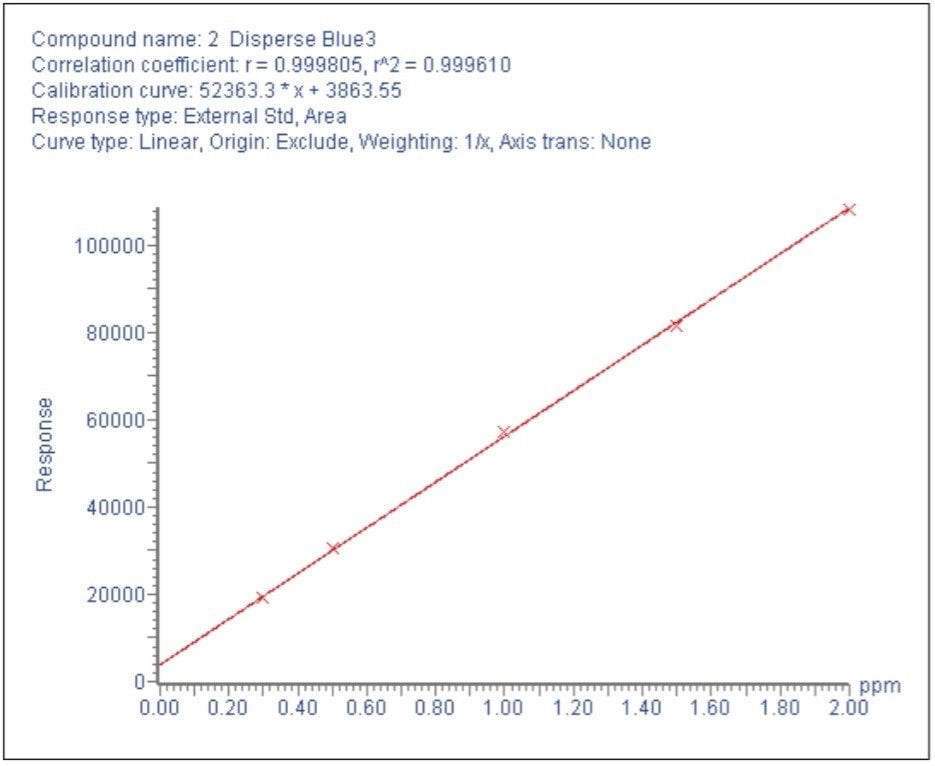

Current EU legislation prohibits the use of sensitizing dyes in textiles, while allowing 5 ppm limit on the other dyes. Quantitation was also carried out with concentrations ranging from 0.3 to 2.0 ppm, and linearity of >0.997 was achieved for all the dyes. The calibration curve of Disperse Blue 3 is shown in Figure 2.

The ACQUITY UPLC H-Class System with the ACQUITY QDa Detector provides a faster and more reliable analytical tool for the identification and quantification of synthetic dyes. Two methods of less than 5 minutes have been developed for both positive and negative ionizing dyes that provide increased throughput and reduced solvent usage.

The ACQUITY QDa Detector can also be easily integrated into current LC-UV analysis methods which allows unsurpassed sensitivity and selectivity, with limits of detection achieved well below the EU regulatory limit of 5 ppm.

720005194, October 2014