This application note demonstrates a simple method for the analysis of soft drink additives with the utilization of Breeze QS System and XBridge BEH Phenyl XP Columns and in turn improving the overall workplace efficiency in a manufacturing environment.

The soft drink market is an important profit center for several beverage manufacturers. These products often contain caffeine as an energy booster, sodium benzoate and potassium sorbate as preservatives, and the diet formulations of artificial sweeteners acesulfame K, aspartame, and saccharin. A beverage may contain any combination of these additives in varying amounts.

For quality control purposes, adherence to target ranges of analytes at specified values is critical. In this study, we show the efficacy of Waters Breeze QS System and XBridge BEH Phenyl XP Columns in achieving these goals.

One Bottle of Waters Beverage Analysis Standards (p/n: 186006008) was poured into one bottle of Waters Beverage Analysis Standards Solid (p/n: 186006010). The bottle containing this mixture was capped tightly and shaken vigorously until the aspartame was completely dissolved.

Samples of a diet cola and diet fruit soft drink were sonicated to remove carbonation and filtered through a 0.22-μL PVDF filter. This was the only sample preparation necessary.

|

LC conditions |

|

|

System: |

Breeze QS |

|

Run time: |

10.0 min |

|

Column: |

XBridge BEH Phenyl XP, 2.5 μm, 4.6 × 50 mm (p/n: 186006073) |

|

Vial: |

LCGC Certified Clear Glass Recovery (p/n: 186003270) |

|

Temp.: |

35 °C |

|

Mobile phase: |

Waters Beverage Mobile Phase Reagent (p/n: 186006006) |

|

Flow rate: |

1.0 mL/min (isocratic) |

|

Injection volume: |

5 μL |

|

UV detection: |

214 nm |

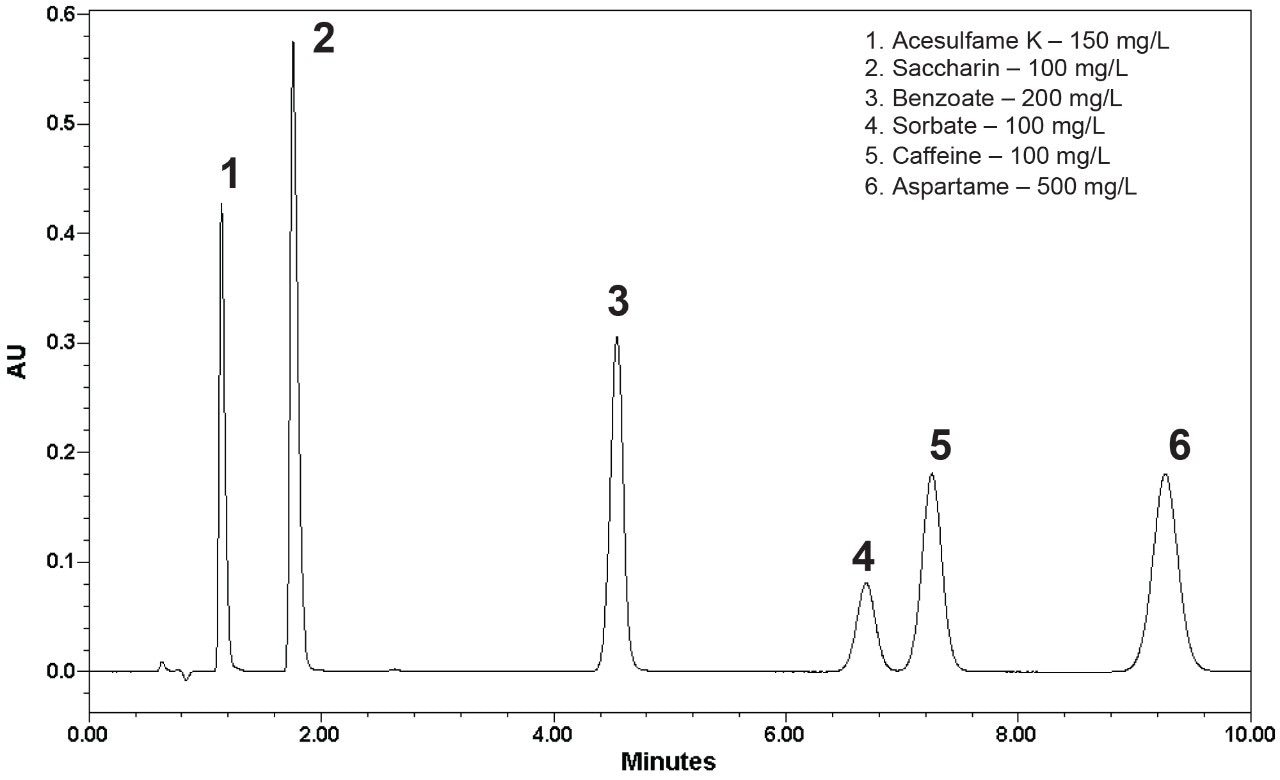

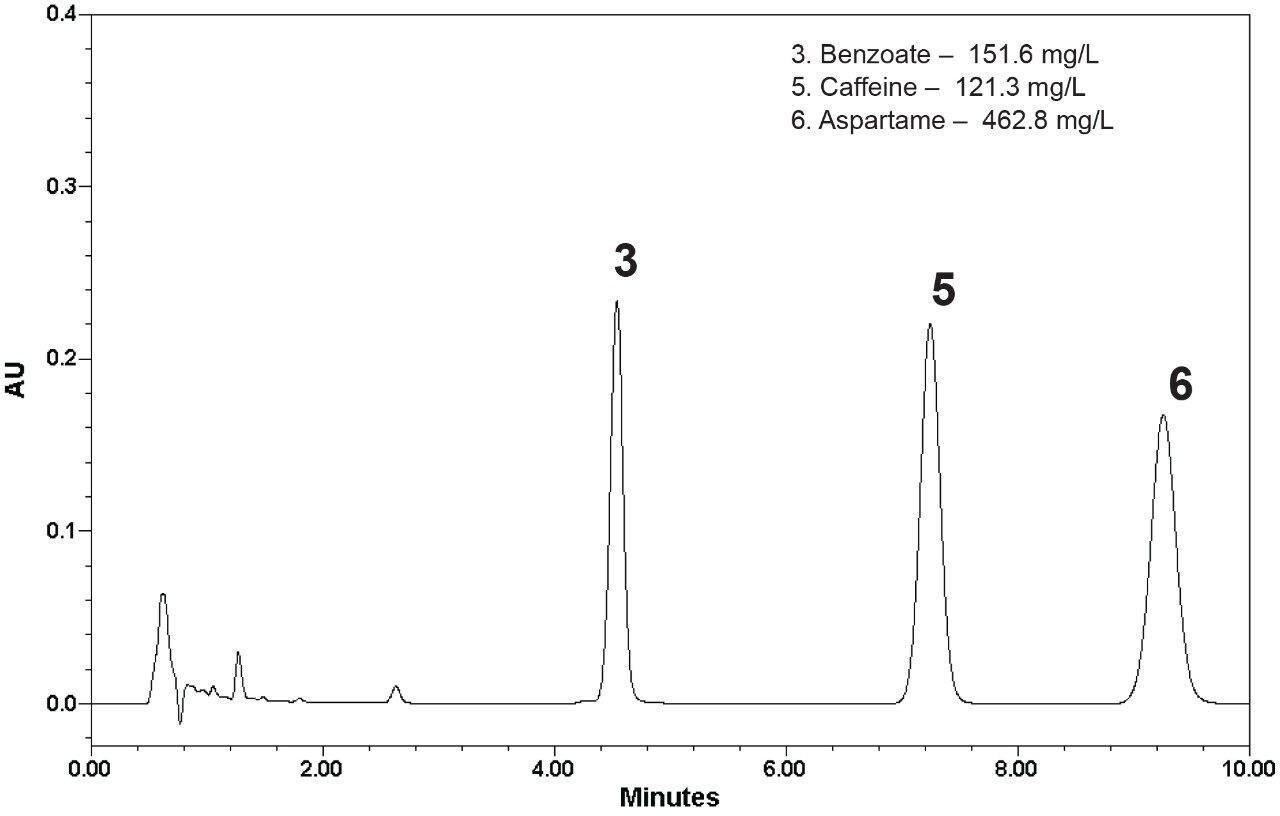

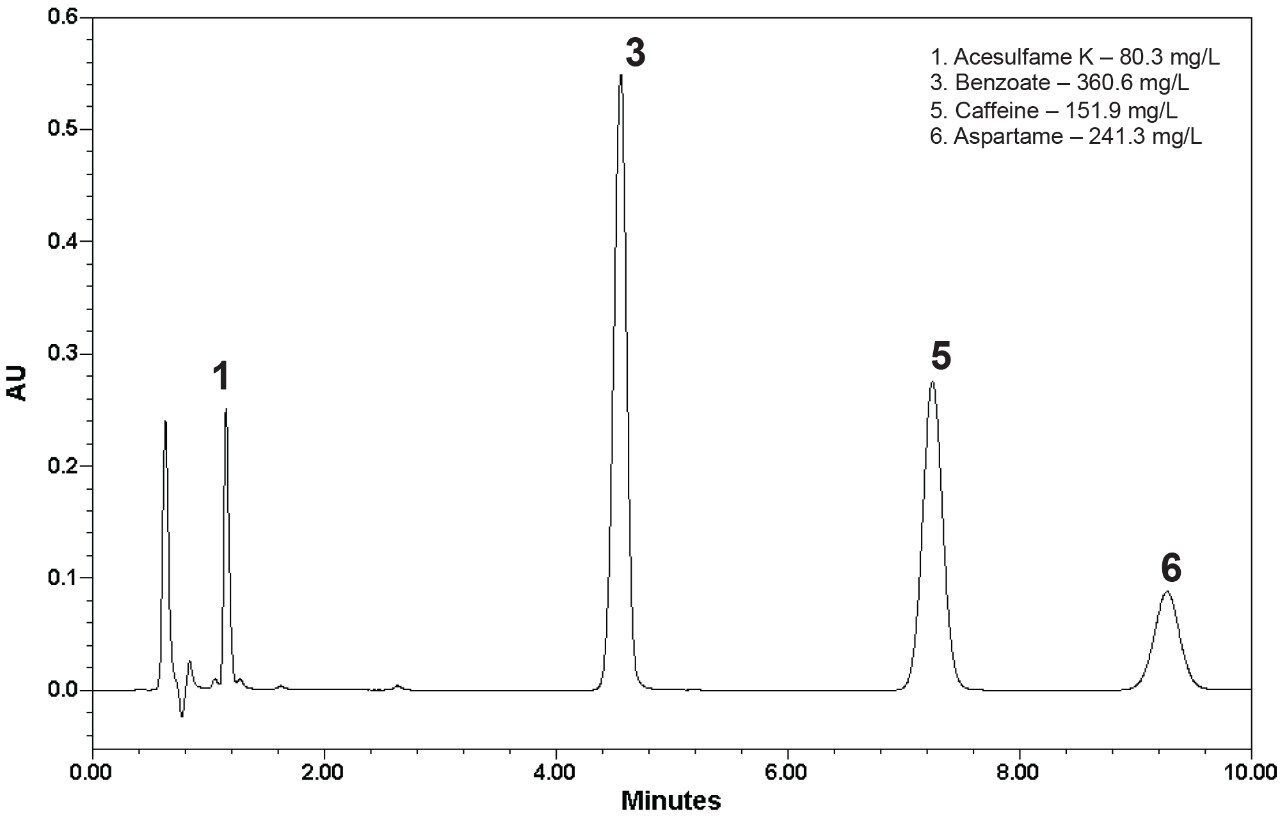

Figure 1 shows a chromatogram of the beverage analysis standard. Figures 2 and 3 show the chromatograms of a diet cola and fruit flavored beverage, respectively. The sample beverages were quantified against the soft drink standard using a single-point linear calibration. Note that there is a baseline separation of all analytes with a run time of less than 10 minutes. Using this isocratic method, there is no need for column re-equilibration between injections. The ethanol-based mobile phase has no toxicity issues, resulting in reduced disposal costs.

This application note demonstrates a simple method for the analysis of soft drink additives. Implementation of this procedure in a manufacturing environment has the capacity to improve overall workplace efficiency.

720006601, July 2019