This application note details a rapid method that combines an SPE method for melamine in liquid milk and infant formula with UPLC-MS/MS detection that can enable detection and quantitation of melamine across a wide range of concentrations.

An increased incidence of kidney stones and renal failure in infants has been reported in China, believed to be associated with the ingestion of infant formula contaminated with melamine. It appears that nitrogen rich melamine was added to raw milk to boost its apparent protein content, which is assessed through determination of the nitrogen content by the Kjeldahl method.

Melamine has many industrial uses that include the production of laminates, adhesives, and melamine resins. Some of these products may become food contact materials, yielding detectable residues in food. Additionally, there are reports that melamine is a metabolite of the pesticide cyromazine. Taking these widespread sources into account, an oral uptake estimate for melamine is 0.007 mg/kg body weight/day.1

A tolerable daily intake (TDI) has been established by the U.S. Food and Drug Administration (FDA) at 0.63 mg/kg body weight2, while the TDI quoted by the European Food Safety Authority (EFSA) is in broad agreement at 0.50 mg/kg body weight.3

Maximum permitted concentrations for melamine in food for adults are approximately 2.5 mg/kg (EU, U.S., and Hong Kong). However, Hong Kong set a tolerance at 1 mg/kg in infant foods. The U.S. FDA stated that no tolerance can be set in infant formula because there are too many uncertainties to rule out public health concerns at a specific level4 and Taiwanese authorities have stated that melamine should not be detected in any food using the most sensitive instrumentation.

Hence, there is a need for methodology capable of detecting and quantifying melamine in milk products from parts per million (ppm) levels down to very low parts per billion (ppb) levels.

This application note details a rapid method that combines a specific solid phase extraction (SPE) method for melamine in liquid milk and infant formula with UPLC-MS/MS detection that can enable detection and quantitation of melamine across a wide range of concentrations.

A stock melamine standard (TCI America) was prepared by dis-solving 10 mg melamine in 10 mL of 2% ammonium hydroxide. Working standards were prepared by further dilution in mobile phase.

A stable isotope labeled internal standard for melamine (13C315N3 melamine) was obtained from Cambridge Isotope Laboratories, Inc. and a working internal standard was prepared by dilution in mobile phase.

Whole-fat liquid milk and infant formula were obtained from a local supermarket for use in recovery experiments.

|

LC system: |

Waters ACQUITY UPLC System |

|

Column: |

ACQUITY UPLC BEH HILIC 2.1 x 100 mm, 1.7 μm |

|

Part Number: |

186003461 |

|

Mobile Phase A: |

10 mM ammonium acetate Mobile Phase B: 10 mM ammonium acetate in 95:5 acetonitrile/H2O |

|

Weak needle wash: |

600 μL 10 mM ammonia acetate in 95:5 acetonitrile/H2O |

|

Strong needle wash: |

200 μL 2% ammonium hydroxide |

|

Needle type: |

PEEK |

|

Sr no. |

Time (min) |

Flow rate (mL/min) |

%A |

%B |

Curve |

|---|---|---|---|---|---|

|

1 |

Initial |

0.6 |

0 |

100.0 |

|

|

2 |

0.80 |

0.6 |

0 |

100.0 |

6 |

|

3 |

2.30 |

0.6 |

22 |

78.0 |

6 |

|

4 |

2.80 |

0.6 |

22 |

78.0 |

6 |

|

5 |

2.90 |

0.6 |

0 |

100.0 |

6 |

|

6 |

4.00 |

0.6 |

0 |

100.0 |

6 |

|

MS system: |

Waters ACQUITY TQ Detector |

|

Software: |

Waters MassLynx Software v.4.1 |

|

Polarity: |

ESI+ |

|

Capillary voltage: |

3.00 kV |

|

Cone: |

40.00 V |

|

Source temp.: |

150 °C |

|

Desolvation temp.: |

400 °C |

|

Cone gas flow: |

50 L/hr |

|

Desolvation gas flow: |

900 L/hr |

|

Collision gas flow: |

0.25 mL/min |

Two Multiple Reaction Monitoring (MRM) transitions were monitored to meet relevant criteria for identification and confirmation of melamine. The MRM transitions, dwell times, cone voltages, and collision energies are listed in Table 1.

|

MRM transitions |

Dwell time (sec) |

Cone voltage (V) |

Collision energy (eV) |

|---|---|---|---|

|

127 > 85 |

0.04 |

40 |

17 |

|

127 > 68 |

0.04 |

40 |

25 |

Table 1. ESI positive MRM conditions for melamine.

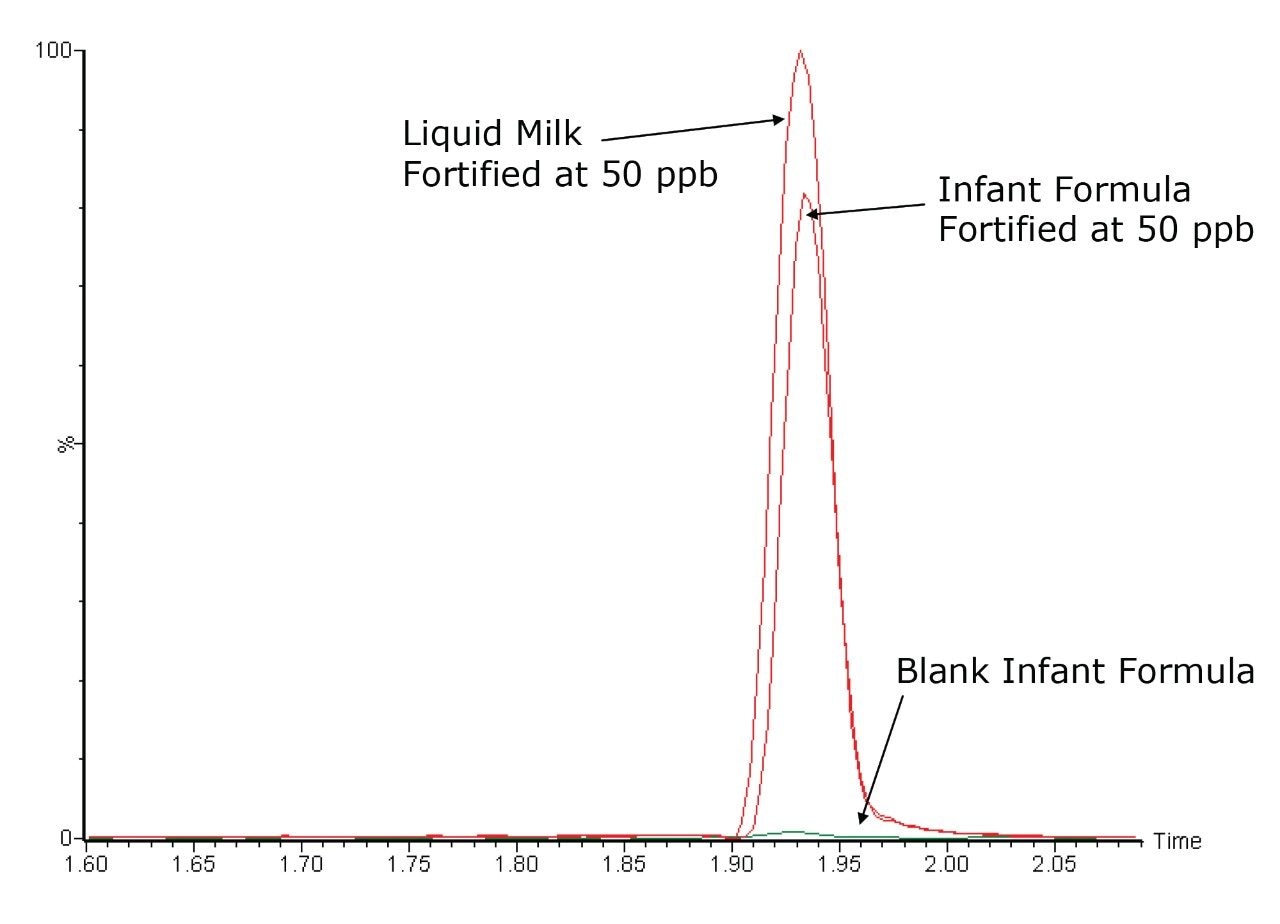

To evaluate extraction efficiency of the method, the infant formula was fortified at ten concentrations in duplicate across the range 0.02 ppm to 20 ppm (0.01 ppm to 10 ppm for liquid milk). Although internal standard is usually added prior to extraction to correct for extraction efficiency, during this experiment, it was added after extraction, only correcting for efficiency of ionization. During this small study, average absolute recovery was approximately 80% for infant formula and approximately 90% for whole liquid milk, as shown in Figure 1.

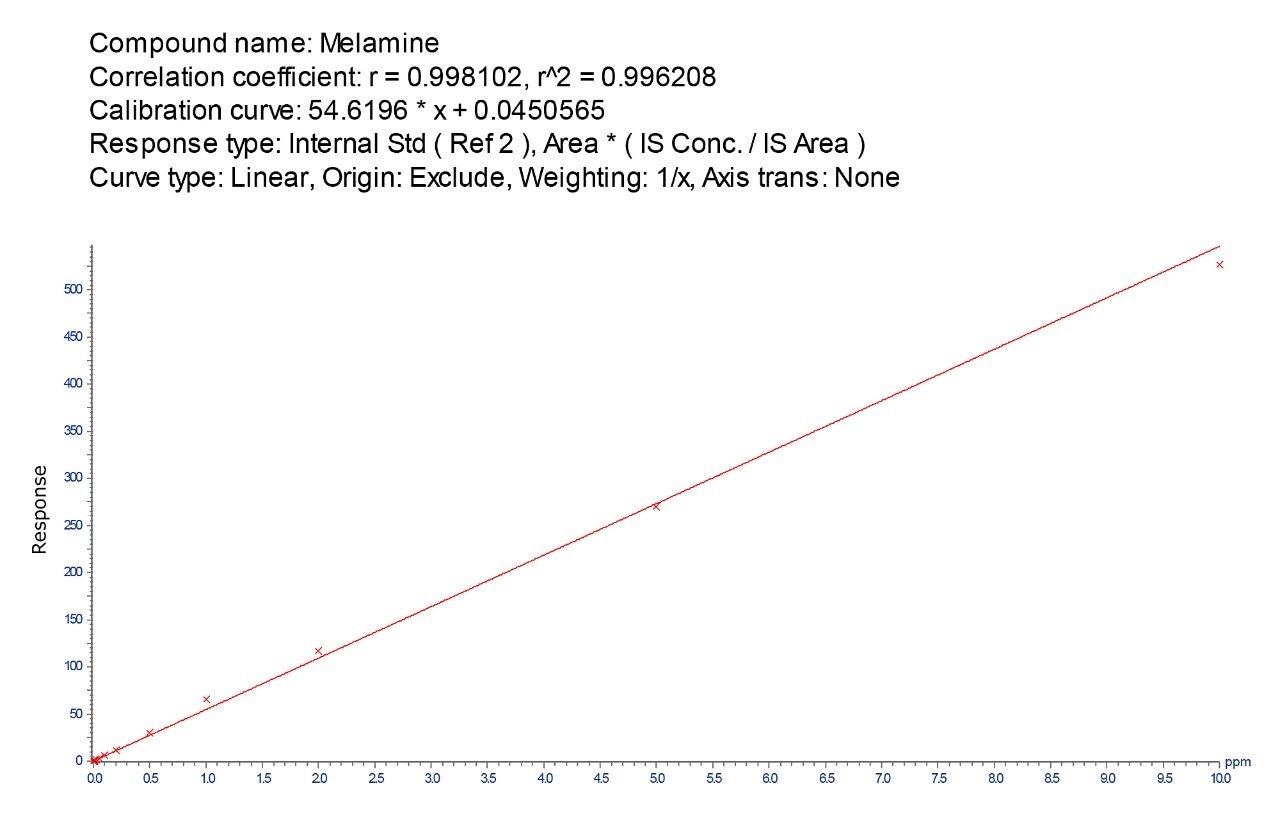

By including stable isotope-labeled internal standard in the extracts, the linearity of the method could effectively be extended to cover the range of concentration stated above for liquid milk, permitting the use of this procedure for detection and quantitation of melamine in foods destined for both adults and infants (Figure 2).

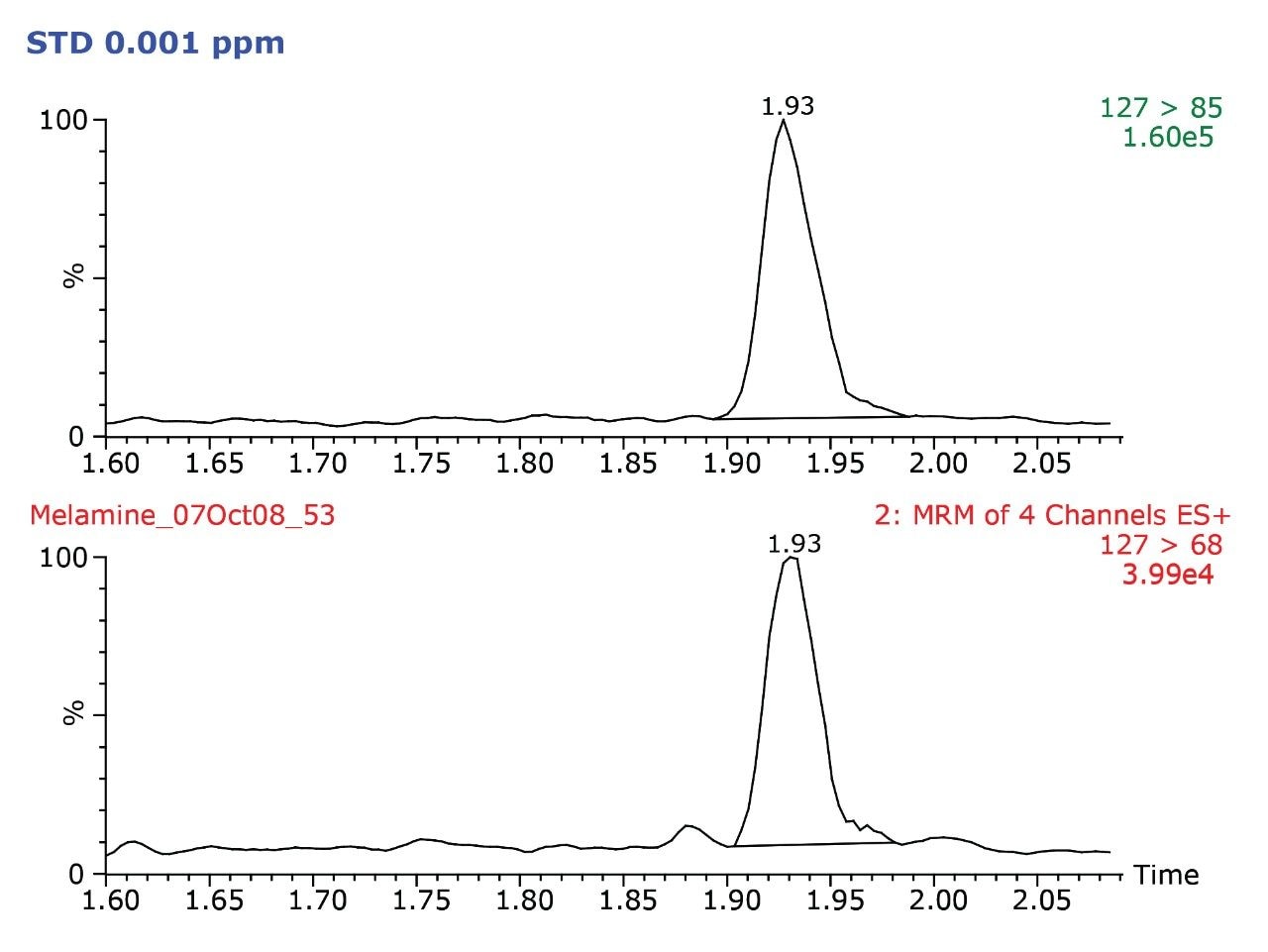

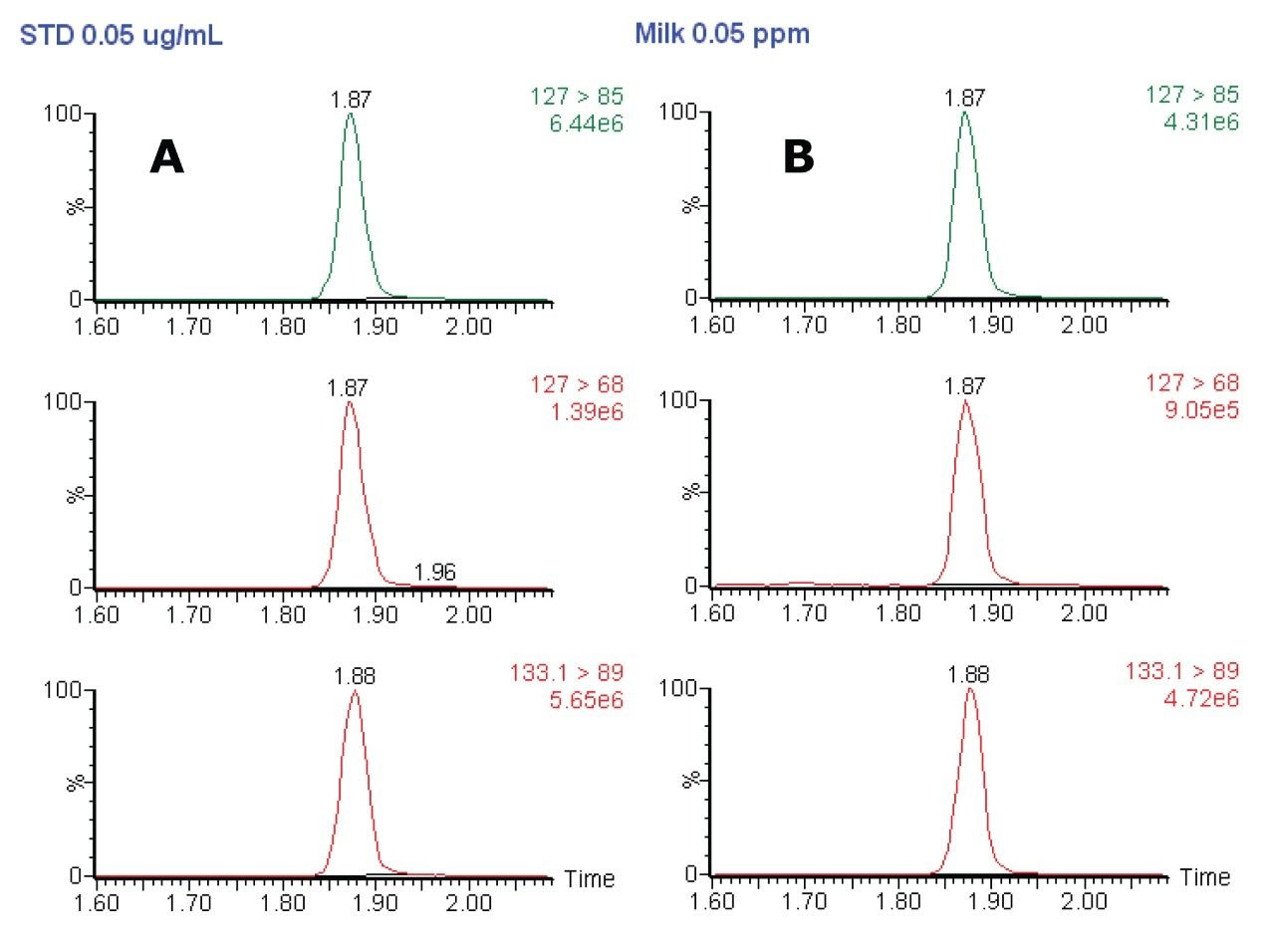

Employing UPLC in combination with MS/MS detection on the TQ Detector permitted concentrations equivalent to 1 ppb or less to be detected and confirmed, by MRM transitions, as shown in Figure 3.

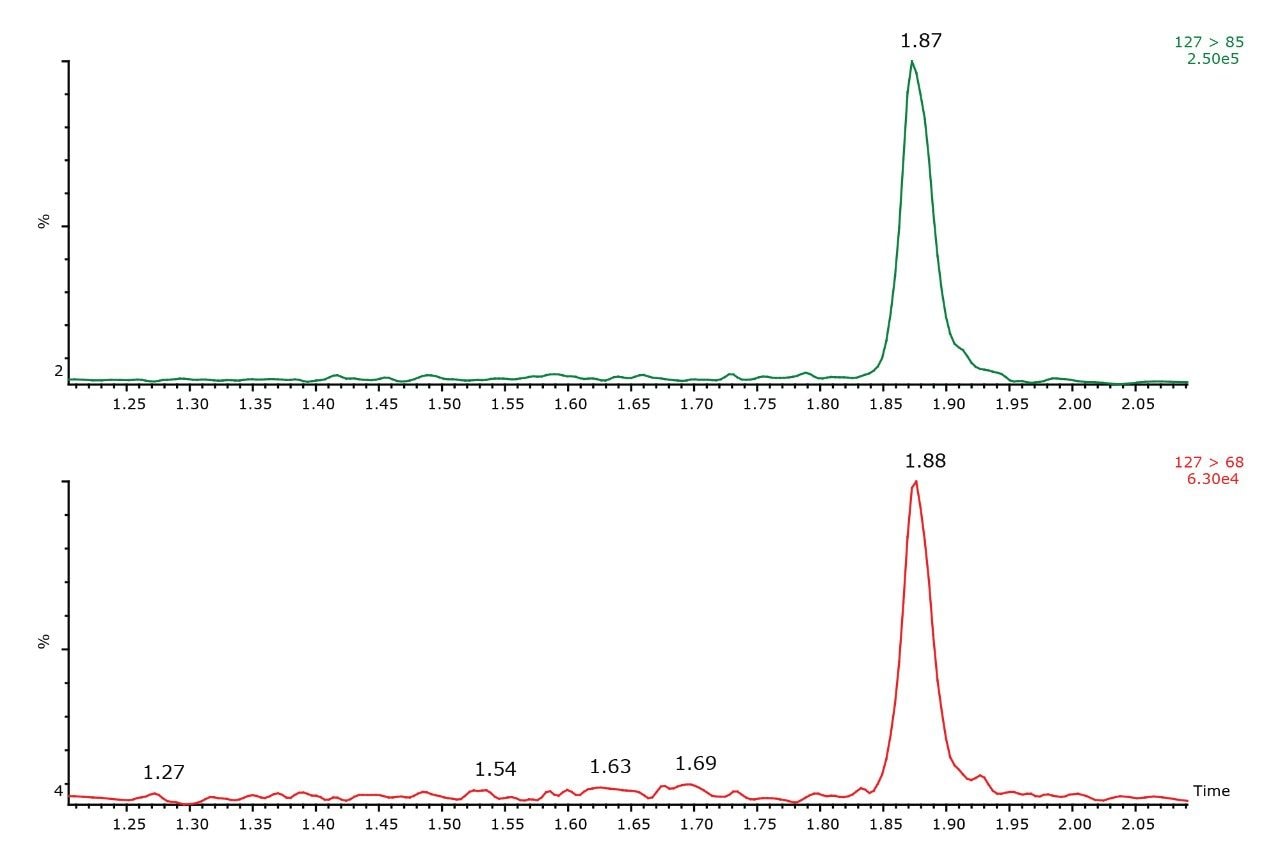

Taiwanese authorities have stated that melamine should not be detected in any foods, whereas, the U.S. FDA has stated that a tolerance of 2.5 ppm may be applied to food other than infant formula for which a level has not been set. This method was applied to the detection of melamine in infant formula and demonstrated detection and confirmation at the LOQ of 20 ppb, as shown in Figure 4.

Using MRMs for melamine and by the inclusion of a stable isotope-labeled internal standard, infant formula and liquid milk could be screened, confirmed, and the concentration accurately quantified in a single analysis, as shown in Figure 5.

There is a need for a rapid, sensitive method for the analysis of melamine in infant formula and other milk products. This work describes a method that employs a specific solid phase extraction of melamine, using Oasis MCX, from these products following acidification. It is worth noting that the method described here used perchloric acid, but preliminary studies indicate that trichloroacetic acid may equally be substituted.

Following extraction, the ACQUITY UPLC System combined with the TQ Detector provides rapid chromatography (retention time < 2 minutes), with tandem MS detection. Application of UPLC offers significant advantages for speed of analysis resulting in high throughput. Combining UPLC with the TQ detector also offers excellent sensitivity. The addition of a stable isotope internal standard affords good linearity across a wide range of concentrations, resulting in confident quantification of melamine in infant milk and formula.

With the desire of food producers worldwide to demonstrate due diligence regarding the safety and quality of milk products, the method described offers significant business advantages in meeting the challenge of timely, uninterrupted supply of product whilst simultaneously and unequivocally ensuring the safety of consumers.

720002823, October 2008