This is an Application Brief and does not contain a detailed Experimental section.

The full characterization of food materials, processes, and products is essential to assuring consistent product quality. Monitoring the free amino acid profile can be a useful tool in assessing the stages of production as well as a final product. Waters turnkey application, UPLC Amino Acid Analysis Solution, has been used to monitor free amino acids in raw materials, processes, and final product quality of food products. As an example of this application, we have followed a yeast fermentation in the production of a beer.

Food products have different desirability and value based in part on palatability and flavor profile. Controlling the manufacture of these food products to consistently meet the expectations and requirements of the consumer can be a difficult challenge. The materials and process that are combined to achieve that finished product can introduce many variables that can ultimately alter the product characteristics.

To ensure product quality, consistency in starting materials is required. Food constituents can have different characteristics based on origin and seasonal variation. The natural products may also have been processed by another manufacturer. All of these factors become further complicated when applying them to a complex process, such as fermentation.

It is, therefore, necessary to verify the quality of the starting materials. Chemical changes in those materials during processing can be monitored to ensure maximum yield of good product. The analysis of the final product assures that consumers always receive quality product. One useful class of chemical markers is amino acids.

Free amino acids can exist as nutrients, metabolic intermediates, or as waste products to a biological process and can be used to identify the genotype and origin of a plant. In a similar fashion, amino acids can be used to relate a profile to valuable characteristics in high value foods. By monitoring the free amino acids during and after a process, it is possible to identify and control physiology that affects the product quality.

Waters turnkey application, UPLC Amino Acid Analysis Solution, has been used to monitor free amino acids in raw materials, processes, and final product quality of food products. As an example of this application, we have followed a yeast fermentation in the production of a beer. Characterization of raw materials is demonstrated with the free amino analysis of three different starting fermentation barley malts. Each of these malt varieties were then carried through a fermentation process, and the changes in free amino acid levels were observed at different stages of the fermentation. Finally, free amino acid analysis was performed on multiple lots of two commercially-produced pale ales to differentiate the brands and determine the manufacturing lot consistency.

The derivatization reagent reacts with both primary and secondary amines at an optimal pH of 8.5. The batch-derivatized samples are stable at room temperature for up to one week when tightly capped. Conditions for pre-column derivatization and analysis are described in detail in the Waters UPLC Amino Acid Analysis Solution System Guide (P/N 71500129702).

The Waters UPLC Amino Acid Analysis Application Solution is provided with all the Empower methods necessary for acquisition and processing of the samples, as well as reporting of the results. Details of the methods can be found in the Waters UPLC Amino Acid Analysis Solution System Guide.

|

LC System: |

Waters ACQUITY UPLC System |

|

Column: |

AccQ•Tag Ultra, 2.1 x 100 mm, 1.7 μm |

|

Column Temp: |

60 °C |

|

Sample Temp: |

20 °C |

|

Flow Rate: |

700 μL/min. |

|

Mobile Phase A: |

1:10 Dilution of AccQ•Tag Ultra Eluent A with Milli-Q water |

|

Mobile Phase B: |

AccQ•Tag Ultra Eluent B |

|

Weak Needle Wash: |

95:5 Water:Acetonitirile |

|

Strong Needle Wash: |

5:95 Water:Acetonitrile |

|

Gradient: |

AccQ•Tag Ultra Cell Culture Method (provided in the UPLC Amino Acid Analysis Solution) |

|

Total Run Time: |

9.5 min |

|

Injection Volume: |

1 μL, Partial loop with needle overfill |

|

Detection: |

UV (TUV), 260 nm |

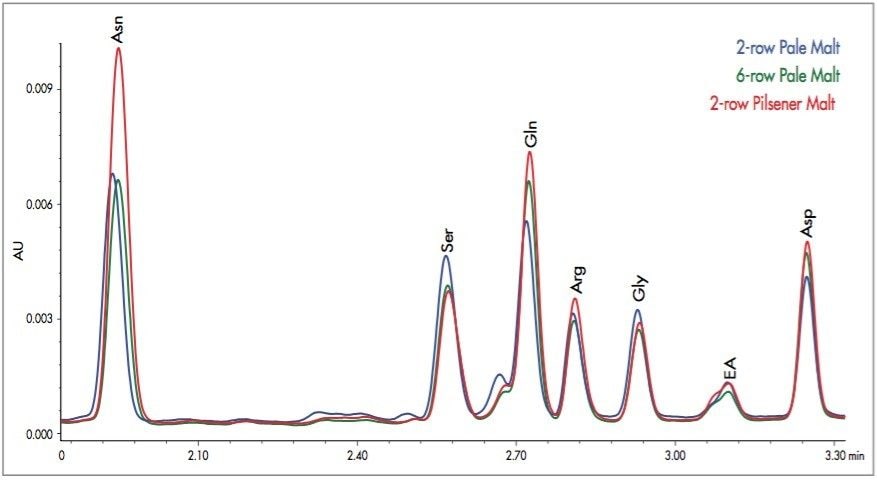

Three batches of the same recipe of beer were produced, each using different starting malts (barley grain). These malts were chosen to represent some of the varietal, regional, seasonal, and malting process differences. This selection reflects the genetic varieties (2-row Pale Malt and 6-row Pale Malt) and malting processes (2-row Pale Malt and 2-row Pilsener Malt). The segment of the amino acid analysis chromatogram of Figure 2 shows the differences in free amino acid levels for the various starting malts. Some amino acids are constant across the different grain varieties, but asparagine (Asn) is higher for the 2-row Pilsener malt. Glutamine (Gln) levels are different for each of the starting malts.

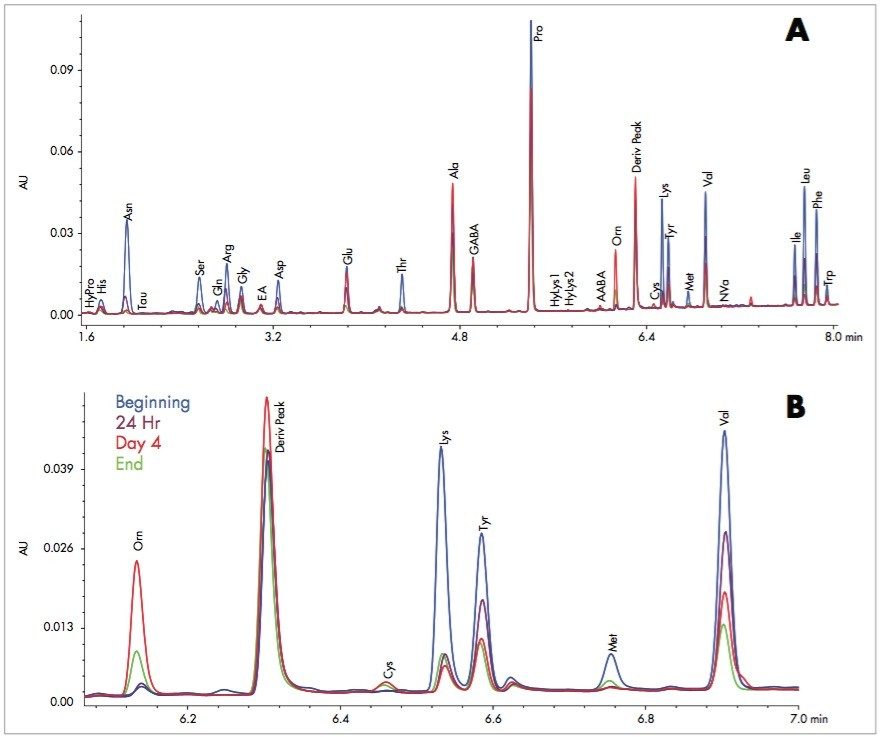

These same three batches used to compare the starting malts were monitored throughout the entire process. Figure 3 shows time-dependent changes throughout primary fermentation. Some amino acids, such as valine (Val), were slowly depleted throughout fermentation. Others, like lysine (Lys), decreased dramatically in the first day of fermentation, and then maintained a constant level. Ornithine (Orn), on the other hand, increased during the first four days of fermentation, then dropped once the yeast activity ceased.

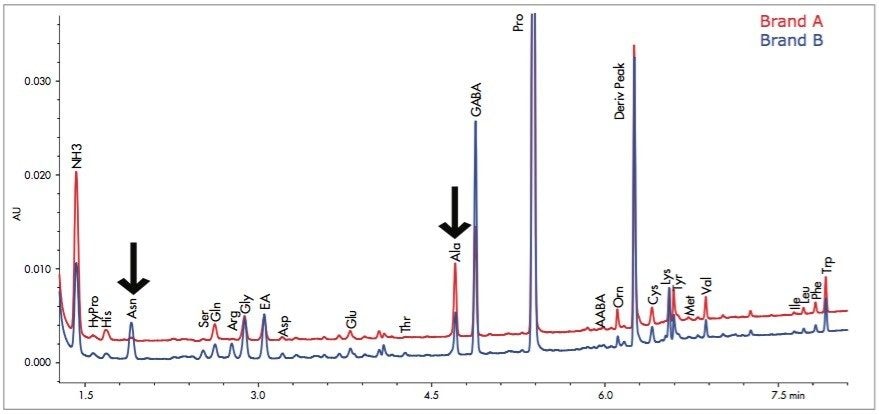

To demonstrate the analysis of the method for finished products, two commercially-produced pale ales were analyzed for their free amino acid content. The chromatogram in Figure 4 shows the differences between the two brands. Brand B has higher amounts of free amino acids than Brand A. In particular, there is a significant amount of asparagine in Brand B, while it is virtually absent from the Brand A. Alanine, on the other hand, is higher in Brand A.

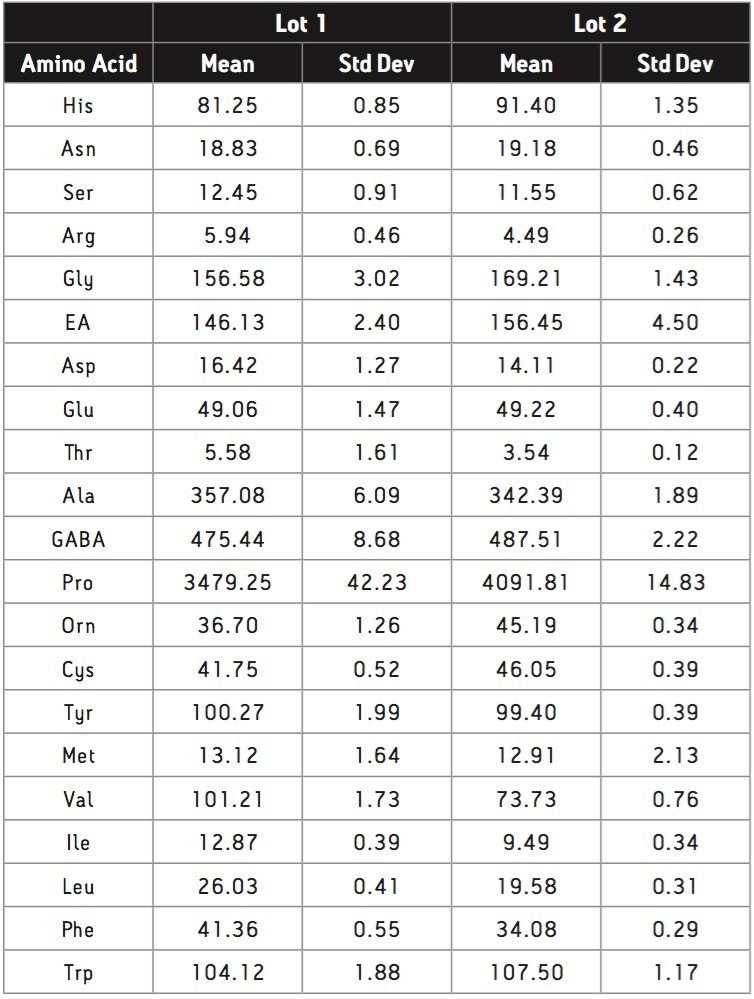

Multiple lots were tested for each brand of the pale ales. Table 1 shows the average amounts for two separate lots of Brand B of pale ale. The small standard deviations for the six determinations allows for recognition of differences between the lots. While the asparagine and glutamic acid levels are the same in each lot, within the variability of the data set, significant differences can be observed for proline, valine, and alanine. These differences could indicate a change to the materials or process.

The full characterization of food materials, processes, and products is essential to assuring consistent product quality. Monitoring the free amino acid profile can be a useful tool in assessing the stages of production as well as a final product.

Waters UPLC Amino Acid Analysis Solution was successfully applied to all stages of the process. Neither modifications to the method nor any special sample preparation was required.

Differences observed in the levels of amino acids for the starting malts show how raw materials can be verified for consistency prior to use in a manufacturing process.

Quantitative changes during the fermentation process were observed. Both increasing and decreasing concentrations of amino acids were readily measured.

Analysis of finished product showed differences both between brands as well as between lots of a single brand. These reliable measurements of chemical markers can reflect palatability or consumer acceptance of the product.

Waters UPLC Amino Acid Analysis Solution is a total system solution that is well suited to provide meaningful results for these applications. The small amounts of sample required make additional sample handling unnecessary in many cases. The rapid and reproducible results provide confidence to the user in making quality decisions about the material and processes that go into making a food product.

720003357, March 2010