Development of a Fully Scalable High Efficiency 5 µm Solid-Core Particle to Support HPLC Workflows

Abstract

The use of superficially porous, or solid-core, stationary phases for liquid chromatography workflows dates to the 1960’s where glass beads were used as the non-porous center and layers of porous material were adhered to it.1 While these columns were used for ion exchange chromatography, eventually the use of these particles migrated to reversed-phase liquid chromatography. The use of these particles increases column efficiency without added pressure increases compared to fully porous particles of the same size. These particles are now present in a variety of workflows and are available from multiple vendors across particle sizes allowing their use on HPLC instrumentation as well as newer UHPLC instruments as well. Their use in HPLC workflows is of particular interest as they can increase overall separation efficiency without the need for newer and often times more expensive instrumentation.

Having fully scalable technology across particle sizes is particularly important for the development of methods which will be transferred to other laboratories. This allows seamless migration of these methods without the need for costly rework or re-development of the method. Additionally, the use of a column which can be scaled across particle sizes allows any laboratory to employ the method regardless of what instrumentation they have available. This application note examines three different vendors of solid-core materials and compares the “scalability” of particles from sub-2 µm to 5 µm. Additionally, the column efficiencies of 5 µm particle size solid-core columns from various vendors were also compared using a batch test procedure. Theories will be provided as to why different results are obtained when scaling between particle sizes as well as the discrepancies in column efficiency.

Benefits

- Development of a fully scalable 5 µm solid-core particle stationary phase

- Comparable retention achieved across three particle sizes of CORTECS™ Premier C18 Column stationary phases

- Comparisons to two separate vendors are shown with more accurate scalability of the CORTECS Premier C18 Column phase

Introduction

High Performance Liquid Chromatography (HPLC) is a well understood and widely implemented technology to analyze different samples. While it has many documented methods and uses, the biggest limitation of this platform is the operating pressure and resolution power of the system. Often, these systems operate at ~5,000 psi, sometimes less depending on the manufacturer and the technology used in the HPLC pump. Newer instrumentation has been developed to overcome this limitation, but for many laboratories HPLC systems are still the gold standard for analysis. Due to the lower operational pressures of the system larger particle columns are needed to limit pressure increases. This also means that longer columns are needed to achieve the required column efficiency needed to separate complex samples, especially when fully porous particles are used.

One way to improve separation efficiency is to reduce particle size from 5 µm to 3.5 µm while maintaining column dimensions. This would effectively increase column efficiency and therefore separation performance, but at the cost of increased pressure. Also, scaling to a smaller particle may not be viable as some validated methods do not allow any changes to be made to particle size or column configuration. The use of solid-core particles is another way to improve column efficiency without having to scale method conditions. Solid-core particles are designed to have a non-porous center and a porous outer layer. This improves several aspects of the column manufacturing process including but not limited to particle size distribution and packing procedure efficiency. Figure 1 shows a cross-section of a solid-core particle (1B) compared to a fully porous particle (1A). Columns packed with solid-core particles often have lower backpressures compared to those packed with fully-porous particles of the same size due to the higher interstitial porosity of the columns.

Having access to 5 µm solid-core particles can greatly impact separation performance of HPLC separations, however not all solid-core columns are the same. Between differences in manufacturing processes, materials, and packing conditions two solid-core columns from different vendors can give drastically different results. In this application, multiple solid-core columns are compared. First, efficiency measurements were performed using an Alliance™ HPLC System to determine the impact of their use on an HPLC System, looking not only at efficiency but also system pressure. Next, a scaling experiment was performed using solid-core columns ranging from sub-2 µm to 5 µm from three different vendors. Comparisons were made across the scaled experiments to determine the “scalability” of the materials. Having high efficiency columns that are scalable between platforms is vital to ensure longevity of the method, while also adding accessibility in terms of appropriate system platforms that can be used.

Experimental

Scaling Sample Description

Sample mixture containing the following compounds created from stock solutions. Uracil (1 µg/mL), pyrenesulfonic acid (6.5 µg/mL), promethazine (3 µg/mL), amitriptyline (8 µg/mL), butylparaben (3.5 µg/mL), and naphthalene (20 µg/mL) combined and placed on system for injection. A fresh vial of sample was used to evaluate each column.

Efficiency Sample Description

Vials of the Neutrals QC Reference Material (p/n: 186006360) purchased and placed on the system for analysis. Separate vials were used for each column to ensure no evaporative loss of analyte or sample diluent. Each vial contains 10 µL/mL acetone, 0.25 mg/mL naphthalene, and 0.40 mg/mL acenaphthene in 50:50 acetonitrile:water (v:v).

LC Conditions

|

LC system: |

ACQUITY™ UPLC™ System with TUV Detector (Scaling) Alliance HPLC System with TUV Detector (Efficiency) |

|

Detection: |

UV @ 254 nm |

|

Columns (Scaling): |

CORTECS Premier C₁₈, 2.1 x 50 mm, 1.6 µm (p/n: 186007093) CORTECS Premier C₁₈, 2.1 x 50 mm, 2.7 µm (p/n: 186007365) CORTECS Premier C₁₈, 2.1 x 50 mm, 5 µm (p/n: 186010784) Vendor H C₁₈, 2.1 x 50 mm, 2 µm Vendor H C₁₈, 2.1 x 50 mm, 2.7 µm Vendor H C₁₈, 2.1 x 50 mm, 5 µm Vendor A C₁₈, 2.1 x 50 mm, 1.9 µm Vendor A C₁₈, 2.1 x 50 mm, 2.7 µm Vendor A C₁₈, 2.1 x 50 mm, 4 µm |

|

Columns (Efficiency): |

Fully Porous C₁₈, 4.6 x 50 mm, 5 µm Fully Porous C₁₈, 4.6 x 50 mm, 3.5 µm CORTECS Premier C₁₈, 4.6 x 50 mm, 5 µm (p/n: 186010790) Vendor H C₁₈, 4.6 x 50 mm, 5 µm Vendor S C₁₈, 4.6 x 50 mm, 5 µm Vendor A C₁₈, 4.6 x 50 mm, 4 µm Vendor P C₁₈, 4.6 x 50 mm, 5 µm Vendor M RP₁₈, 4.6 x 50 mm, 5 µm |

|

Column temperature: |

30 °C |

|

Sample temperature: |

10 °C |

|

Injection volume: |

3.0 µL (Scaling) 2.0 µL (Efficiency) |

|

Flow rate: |

0.25 mL/min (Scaling) 1.03 mL/min (Efficiency – 5 µm) 1.53 mL/min (Efficiency – 3.5 µm) |

|

Mobile phase: |

35/65 (v/v) Acetonitrile/15.4 mM ammonium formate pH 3 (Scaling) 65/35 (v/v) Acetonitrile:Water (Efficiency) |

|

Wash solvent: |

50/50 Acetonitrile/Water |

|

Purge solvent: |

10/90 Acetonitrile/Water |

Data Mangement

|

Chromatography software: |

Empower 3 Service Release 5 |

Results and Discussion

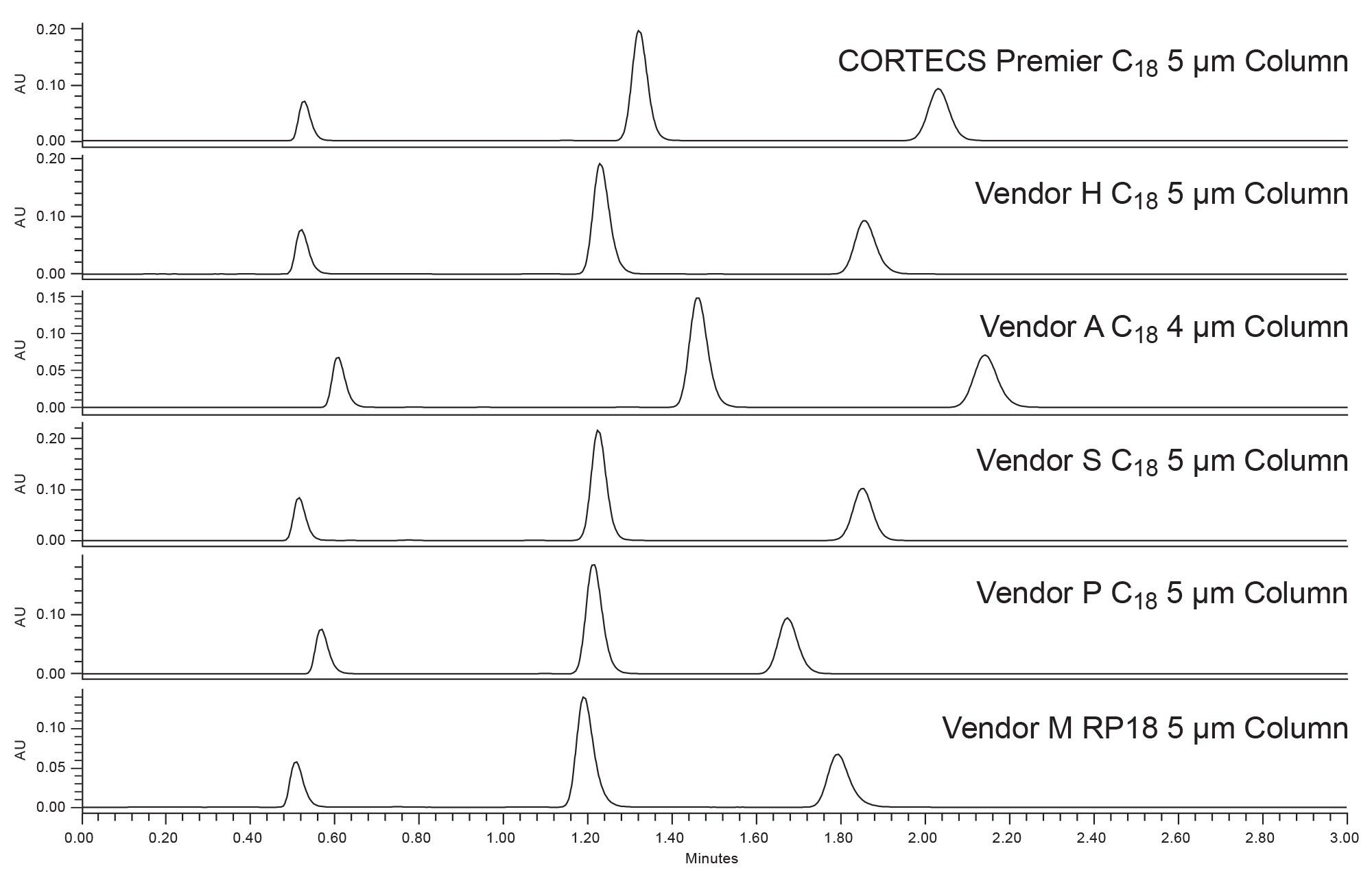

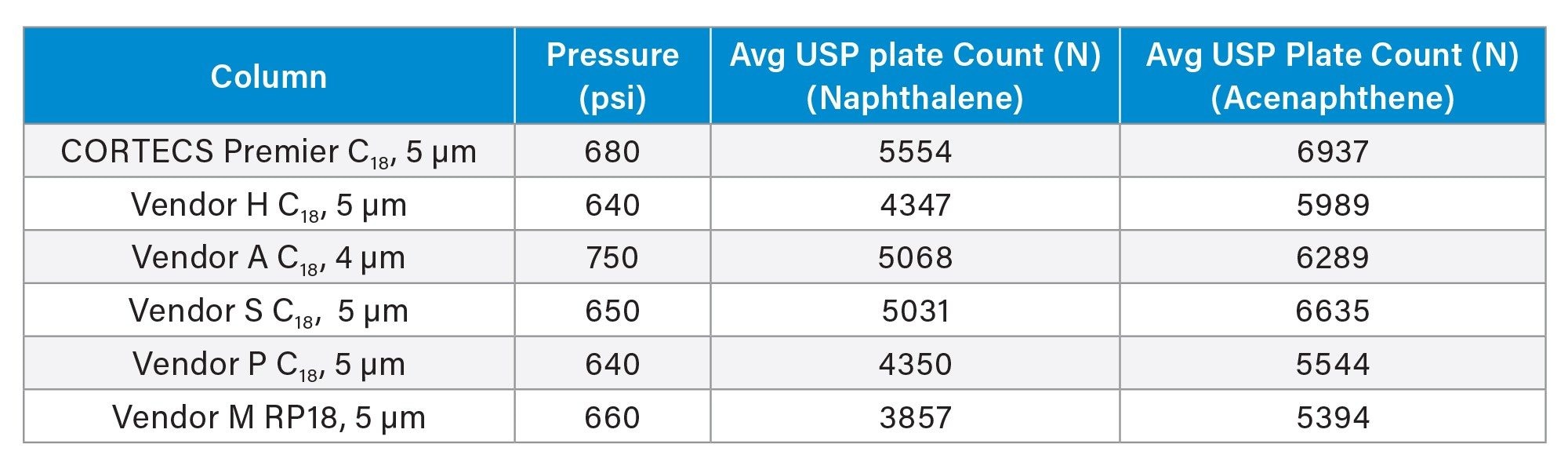

To determine the efficiency of different solid-core particle columns a test was employed using generic conditions which were appropriate for all columns tested. An isocratic separation of three components, acetone, naphthalene and acenaphthene was performed using 65:35 Acetonitrile:Water mobile phase. The average USP plate count (n=5), a measure of column efficiency for both naphthalene and acenapthene was recorded for each column along with system pressure on the Alliance HPLC System. Figure 2 shows the chromatograms for the efficiency test across six solid-core columns from different vendors.

Initial results show comparable retentivity of the six columns with Vendor A having the highest retention followed by the CORTECS Premier C18 Column. The least retentive phases were from Vendor P and Vendor M respectively, although good separation of the components is still achieved. Average USP plate count (n=5) and system pressure was recorded and shown in Table 1.

Starting first with the differences in system pressure, unsurprisingly the Vendor A column showed the highest pressure at ~750 psi. This is understandable given that the particle size is 4 µm compared to the other columns tested which are all listed as 5 µm. The other five columns tested all have approximately the same system pressure in the mid to high 600 psi range. Looking next at USP Plate Count for acenaphthene, it is determined that the CORTECS Premier C18 Column has the highest efficiency with an average value of 6937. The next closest is Vendor S which has an efficiency of 6635, 4% lower than the CORTECS Premier Column. The lowest efficiency columns tested were those from Vendor M and Vendor P which achieved 5394 and 5544 respectively. These are ~20% lower than the CORTECS Premier Column. The discrepancies in efficiency across the vendors products’ can be attributed to differences in manufacturing and packing procedures which can affect overall performance. The CORTECS Premier Columns are all made in-house with tight control over every step of the manufacturing and packing processes in order to create the highest efficiency column possible while also maintaining strong batch to batch reproducibility.

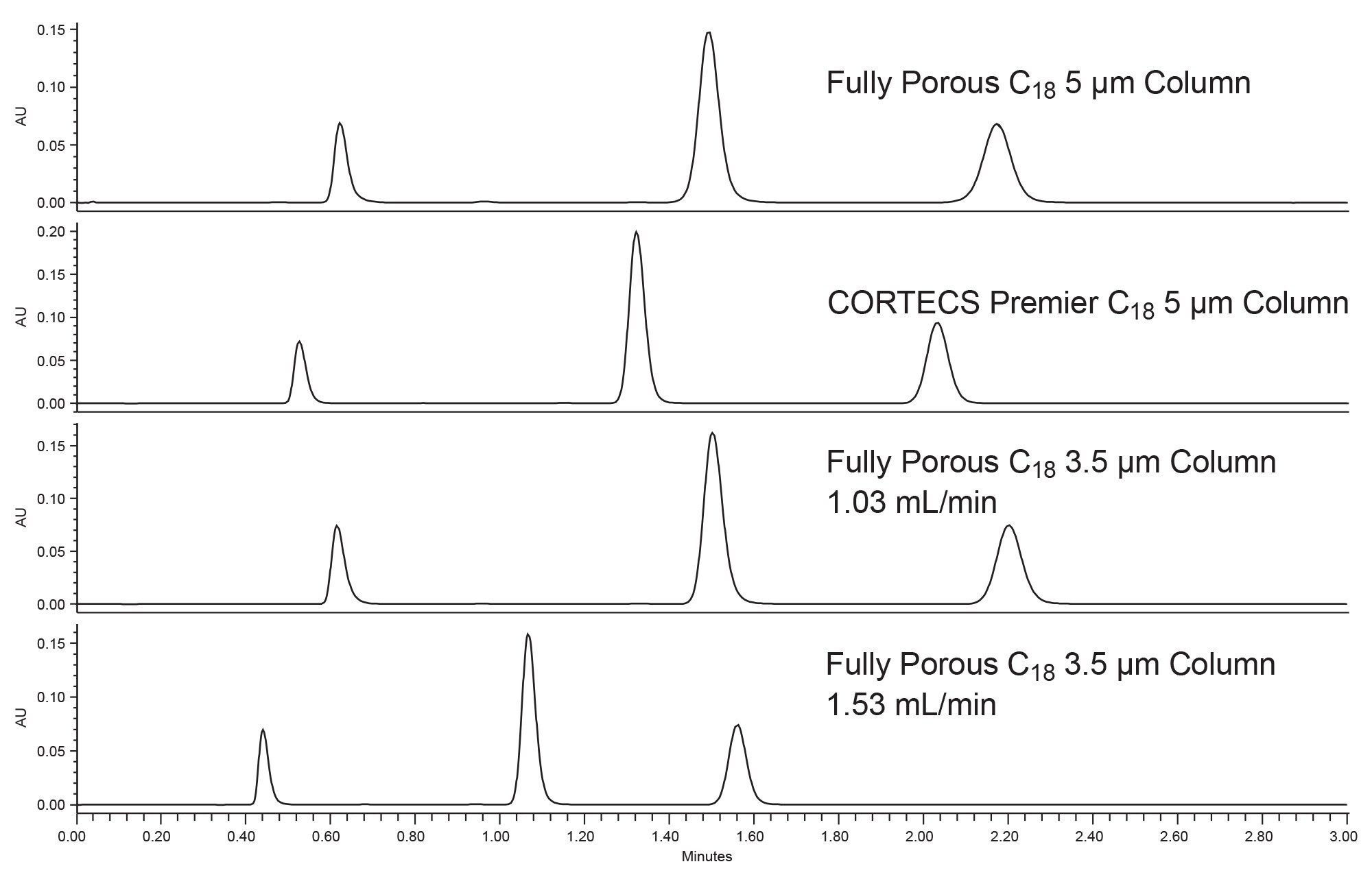

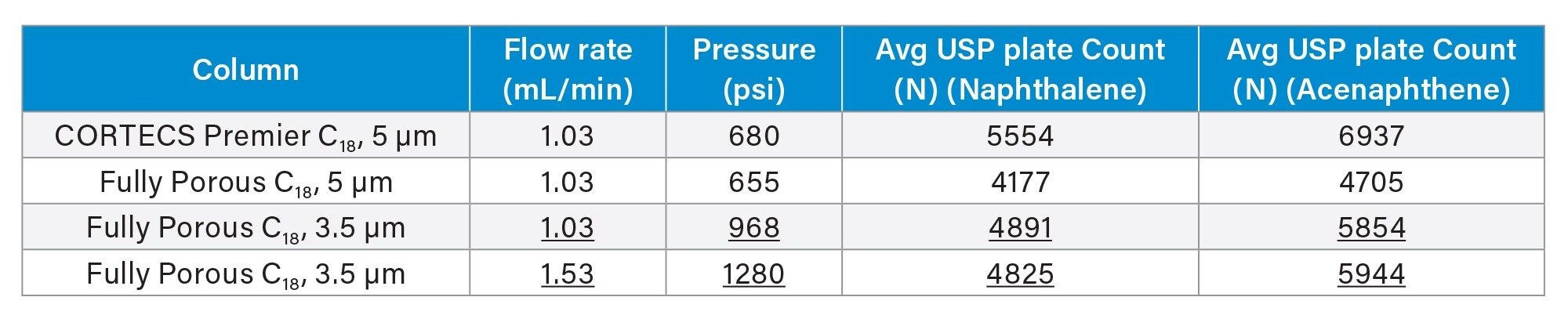

Having a high efficiency solid-core column for critical assays is important, however the argument could be made that using 3.5 µm fully-porous particle columns will also provide increased performance. In order to compare the efficiency of CORTECS Premier C18 5 µm Columns to fully porous columns, the same efficiency test procedure employed above was used. Figure 3 shows the chromatograms for the comparison of a CORTECS Premier C18 5 µm Column to a fully porous C18 5 µm Column, and a fully porous C18 3.5 µm Column. For the 3.5 µm column, two different flow rates were used. A flow rate of 1.03 mL/min was used to match the flow rate of the 5 µm particle columns, and then a scaled flow rate of 1.53 mL/min was used to match linear velocity through the column taking into account the differences in particle size.

As expected the columns show similar retention when the same flow rate is used. In fact, the fully porous 5 µm column and fully porous 3.5 µm column show very good scalability under the same test conditions. The CORTECS Premier C18 5 µm Column shows slightly less retention compared to the 5 µm fully-porous column which is expected as solid-core particles tend to be less retentive. The bottom-most chromatogram shows the 3.5 µm column tested with a scaled flow rate of 1.53 mL/min. In theory, given the smaller particles in the same column length, this column should have higher USP plate count values than the fully porous 5 µm column. Table 2 shows the tabular results of the testing.

Examining the system pressure first the CORTECS Premier Column has only slightly higher pressure compared to the fully porous 5 µm column. This difference is negligible and can be attributed to narrower particle size distribution and lower interstitial porosity of the solid-core particles compared to fully-porous. The fully porous 3.5 µm Column however has a pressure of 968 psi when the same flow rate is used, which is a 50% increase compared to the 5 µm column tested. Scaling the flow rate to 1.53 mL/min further increases the pressure to 1280 psi, essentially double that of the 5 µm columns. For longer column configurations, which are typical in HPLC analyses, the use of the 3.5 µm column may be problematic as the increased pressure associated with the smaller particles may limit flow rates in order to stay within the system’s operational pressure.

Next examining the average USP plate counts for acenaphthene the highest efficiency column is still the CORTECS Premier 5 µm Column. The fully porous 5 µm column had an efficiency of 4705, a 32% decrease compared to the CORTECS Premier Column. The fully porous 3.5 µm Column showed the next highest with a value of 5944 when using the scaled flow rate and 5854 with the original flow rate. So, while the 3.5 µm column does outperform the 5 µm column at the cost of higher system pressure, the CORTECS Premier 5 µm Column is still able to achieve higher efficiencies without the added system pressure. For complex samples requiring long columns, the CORTECS 5 µm particles should provide the best efficiencies without causing the system to overpressure.

Looking back at Figure 3, it is important to note the scalability of the fully porous columns tested. Having a scalable technology provides flexibility for method developers and allows for modernization of older assays. It is important to consider the scalability of a column during method development as many methods eventually get transferred to other labs, which may be limited in what systems are available, and therefore what particle sizes can be used. For already existing methods, having a scalable column technology allows for modernization which can reduce not only run time but also solvent usage. Achieving a fully scalable technology, from sub-2 µm particles all the way up to 5 µm, requires a thorough understanding of the particle morphology as well as tight control of the manufacturing process.

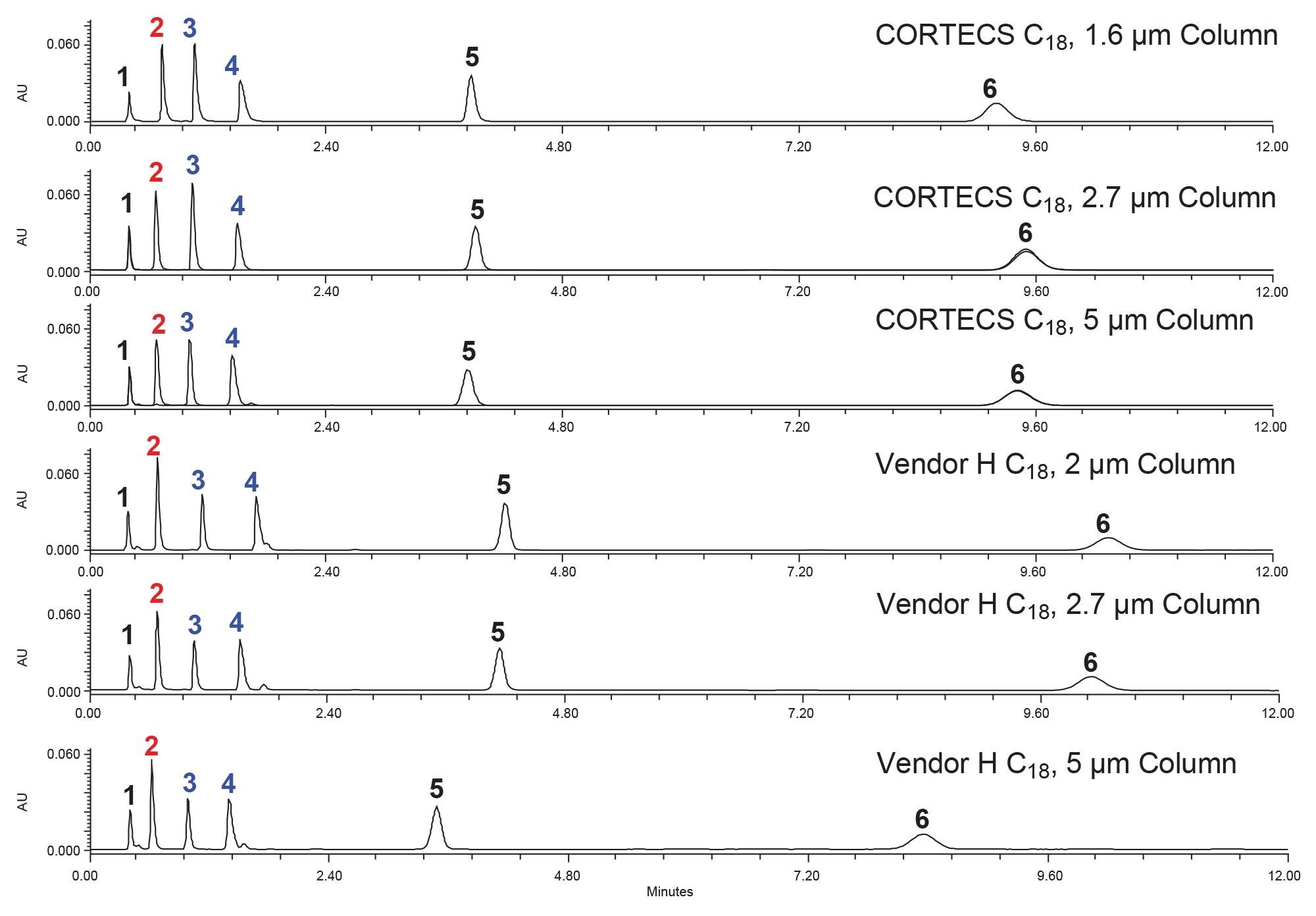

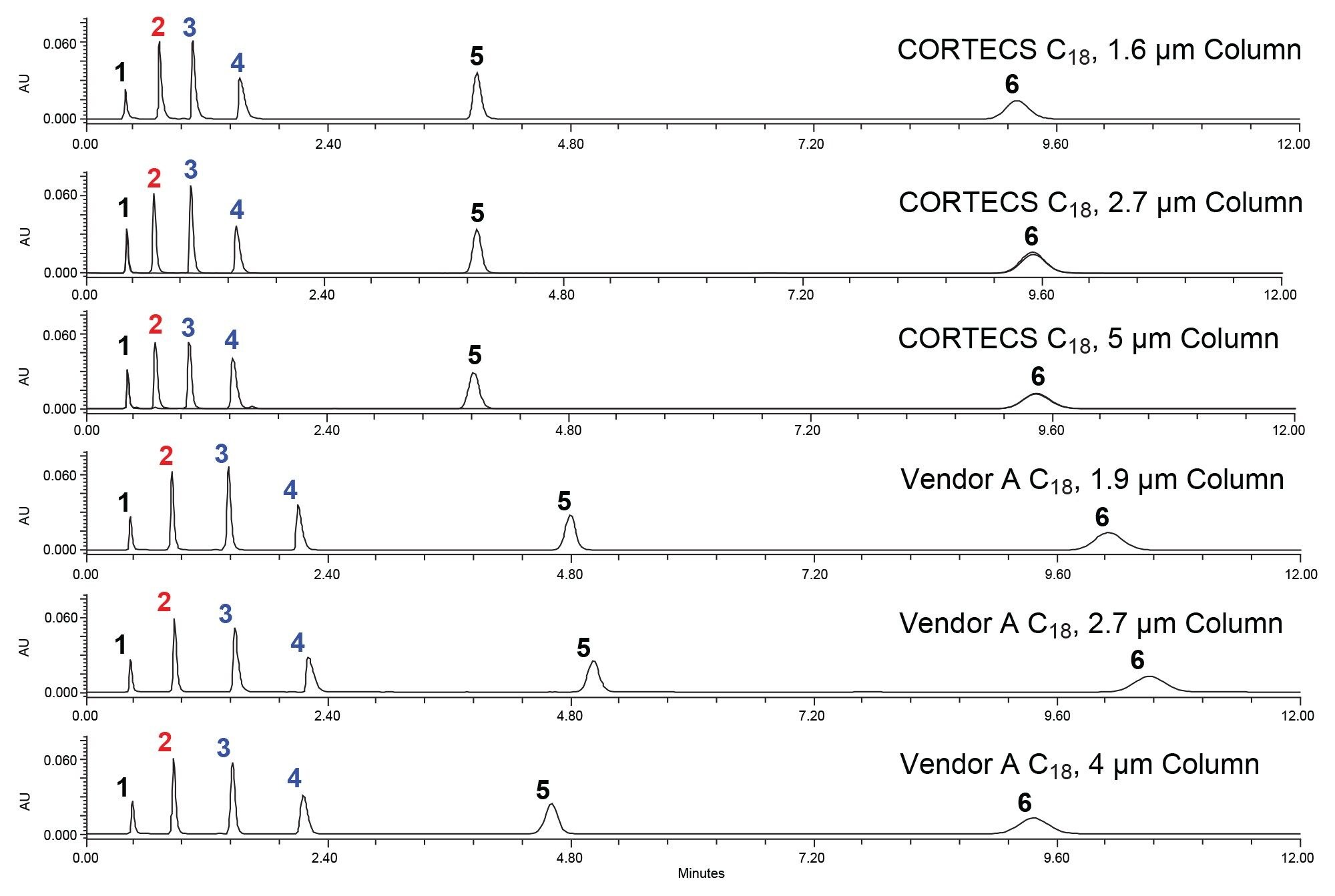

Figure 4 shows the chromatograms of solid-core columns ranging from sub-2 µm up to 5 µm from two separate vendors. Ideally, if the stationary phases are scalable, the retention times should be very similar.

The results show that the CORTECS columns tested are scalable from the 1.6 µm all the way up to the 5 µm. Vendor H however shows that the columns are only scalable between the 2 µm and 2.7 µm columns, with the 5 µm variant having significantly lower retention. This is less than ideal for an assay because it means that a method developed using a Vendor H solid-core C18 column can not be properly scaled up to the 5 µm column without some additional considerations around retention changes, limiting its applicability in both method development as well as method transfer between labs. A similar experiment was performed using Vendor A columns, shown in Figure 5.

Similar to Vendor H, the Vendor A columns show reasonable scalability at the smaller particle sizes, but the larger particle columns, in this case a 4 µm particle shows lower retention. For both Vendor A and Vendor H, the cause of the lower retention of the larger particle size columns could be due to a difference in rho value, or ratio between the solid-core diameter compared to diameter of the final particle. The different rho values could contribute to the changes in retention as higher rho values, indicative of a thinner porous outer layer, lead to less fully porous material in which the analyte is retained. Maintaining a rho value across particle size allows for seamless scalability across particle sizes, allowing methods to be migrated more easily across LC platforms.

CORTECS Premier 5 µm Columns were developed specifically to meet the needs of HPLC users who want to take advantage of the solid-core particles. However, in order to do so, the column must be scalable between particle sizes so that a method developed can be readily transferred between labs which may or may not have different instrument platforms available. CORTECS Premier 5 µm Columns are manufactured with tight control over all aspects of the process, ensuring reliable and reproducible materials ideally suited for HPLC methods which will run for years to come.

Conclusion

HPLC analyses often use large column configurations packed with large particle stationary phases in order to achieve the desired column efficiency. From a practical standpoint, the larger particle sizes are needed to ensure the system does not over-pressurize, typically 5 µm sizes. However, for some assays the use of 3.5 µm particles is possible as they improve column efficiency at the cost of higher system pressure. Some particles available for use on HPLC systems employ solid-core particles which boost column efficiency without increasing system pressure. These columns are especially useful for complicated analyses where efficiency and resolution are required.

CORTECS Premier 5 µm Columns use solid-core particles packed into MaxPeak™ Premier High Performance Surfaces Technology. This provides not only a high efficiency column, but also one that mitigates secondary interactions between analytes and the metal surface of the column hardware. As shown in this application note CORTECS Premier Columns have higher column efficiency than competitive solid-core columns with the same particle sizes. Additionally, the CORTECS particles are fully scalable from 5 µm down to sub-2 µm particle sizes. This allows the CORTECS Premier Columns to be used regardless of instrumentation type.

References

- Majors R. Historical Development in HPLC and UHPLC Column Technology: The Past 25 Years. LCGC International. (2015) 33,11. 818–840.

720008396, June 2024