This is an Application Brief and does not contain a detailed Experimental section.

This application brief illustrates continuing development of the AutoSpec Ultima NT.

Looking to perform ultra low-level trace analysis in complex matrices?

As the market leaders in magnetic sector mass spectrometry, Waters is committed to continuing the development of this technology. With an installed base of more than 620 AutoSpec users worldwide, recent innovations in hardware and software to improve performance, usability and reliability continue to help AutoSpec users become more successful in the laboratory.

The AutoSpec Ultima NT is a double-focusing magnetic sector mass spectrometer using Waters patented tri-sector (EBE) geometry and an especially wide-gap magnet that provides a unique combination of high sensitivity, high resolution and low background noise. This makes the AutoSpec Ultima NT the instrument of choice for ultra low-level trace detection applications, such as the determination of dioxins, furans and other environmental pollutants, and the detection of performance enhancing drugs in sport.

On a magnetic sector instrument, slits are used to restrict the number of ions that enter the analyzer region, and to define the beam prior to detection. The important qualities of any slit design are to have straight, parallel slit blades exactly perpendicular to the optical axis of the beam. The blades have to be durable (to minimize maintenance and down time) and close light tight, ensuring that they are parallel with respect to each other. The positioning of the slits has to be reproducible to a very accurate level, less than 1 μm.

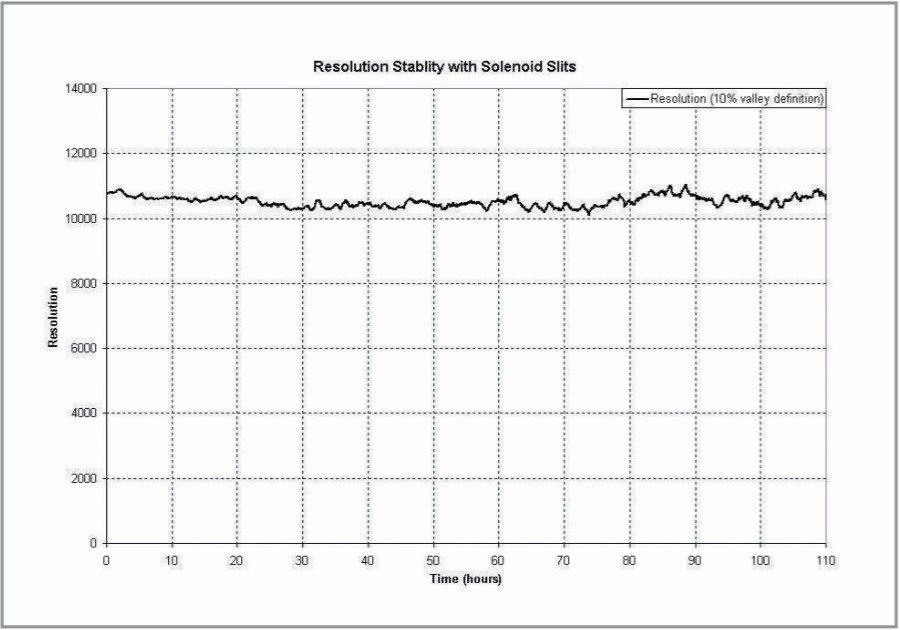

The new slit is actuated by a pair of solenoids applying force to two rare-earth permanent magnets, seated upon slit carriages. The use of the new solenoid controlled slits enables fast, accurate and reproducible slit positioning and is a significant improvement over previous designs. New, sophisticated electronics are used to power the slits via a current-regulated power supply. This provides excellent stability over prolonged periods. The speed of the solenoid slits also facilitates rapid and reproducible automated tuning.

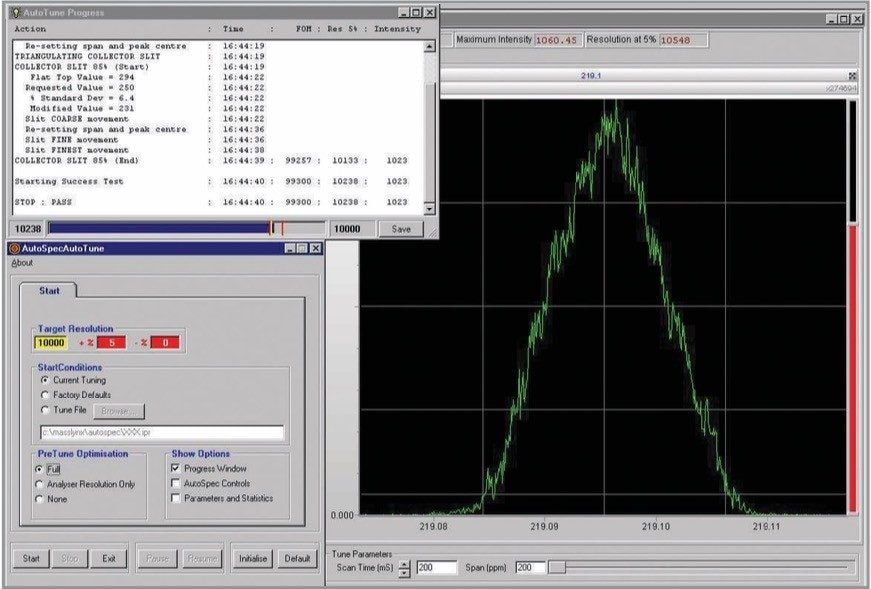

The AutoTune facility has been developed as a time saving tool to assist both inexperienced and experienced instrument users. A sophisticated tuning algorithm, combined with the latest in automated ion optics, can reliably produce the desired resolution with good sensitivity.

The AutoTune program can be set to achieve any resolution between 1000 and 15000 (10% valley definition) from any starting resolution where a peak is visible in the tune window.

Resolution Checker can be added as a post-acquisition processing option to any sample in the sample list, and will provide hardcopy evidence that instrument resolution has been maintained over the analysis period.

Resolution Checker will ascertain the resolution of all reference peaks within the experimental mass range, in an identical fashion to the calibration. The utility will lock on to the reference peak and average a number of scans to derive the mean resolution of the peak. After verifying the resolution of the experiment, Resolution Checker can print a report, providing hard-copy evidence of the resolution at every reference mass checked. If the resolution is outside a specified tolerance, Resolution Checker is capable of "pausing" the sample list, preventing the loss of valuable samples.

This functionality helps to satisfy the stringent conditions of regulatory analytical protocols, such as US EPA Method 1613.

720000718, August 2003